SUCCESS STORY

On a knife’s edge

Fully automated knife sharpening with a robot. This vision once seemed too difficult to achieve. But with the expertise of an experienced systems integrator and the use of a high-performance robot, it has become a reality.

CUSTOMER BENEFITS

- Significant increase in meat production

- High flexibility

- Reliable batch size 1 processing

- Increased throughput

- Reproducible quality of sharpening processes

TASK

Robot-based knife sharpening for meat processing

It is clear from the numbers just how important perfectly sharpened knives are when it comes to meat processing. In comparison to sharpening knives by hand, fully automated sharpening processes can optimize output by 0.5%. This means for 10,000 tons of processed meat, output would increase by 50,000 kilograms.

It is no wonder that Knecht Maschinenbau, a technology leader in automated sharpening and grinding systems for food production, continuously works on optimizing existing processes. Knecht’s approach to the task posed by GLAESS Software & Automation, an experienced systems integrator, was to redesign a robot-based sharpening system that would exceed the performance of the 4-axis portal machines it previously used in terms of quality and flexibility.

The challenge here: Each knife has a unique shape, which changes with use. This means sharpening knives in batch size 1.

SOLUTION

Sharpening with a repeatability of 0.03mm

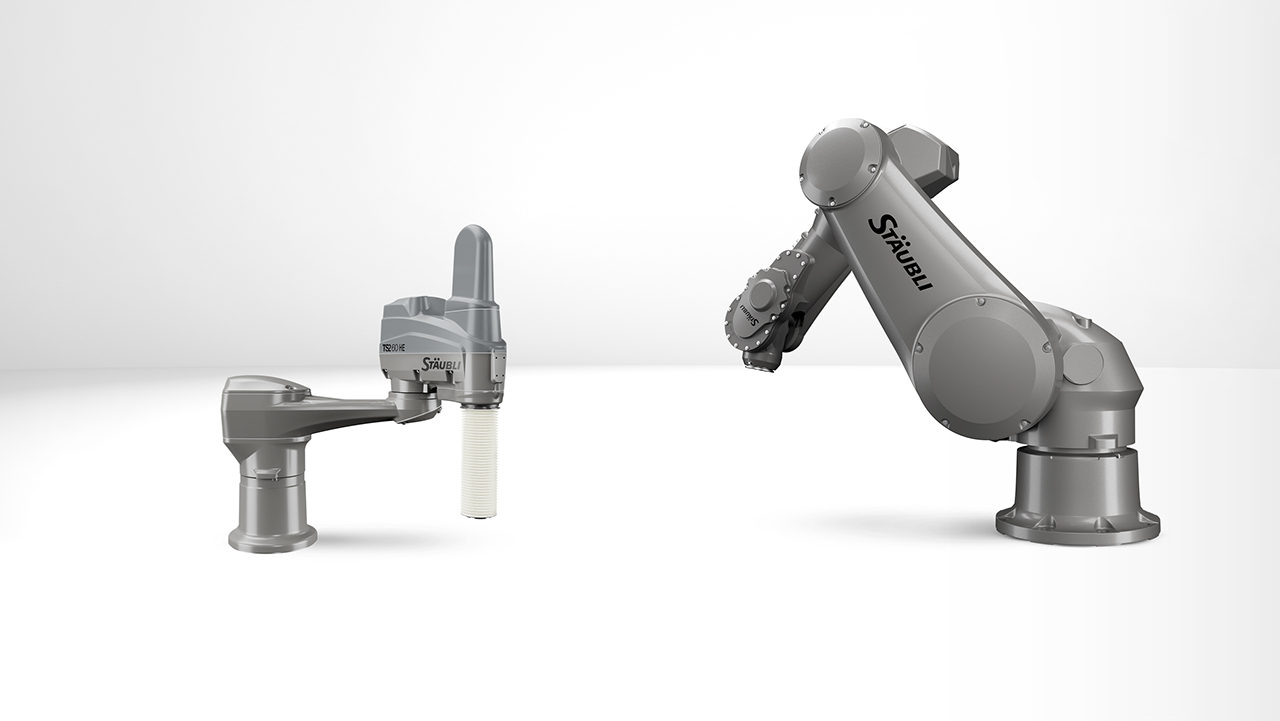

GLAESS’s proprietary sharpening method, which Knecht has implemented with its Series E 50 RT machines, starts by determining the shape of the blade. A highly accurate Stäubli TX2-90 removes a knife from the magazine and passes it through a laser measuring station. The positioning data captured here is sent to the PLC in real time and cached alongside measurement data from the sensor. This data determines the robot’s path.

In the second step, the 6-axis robot precisely guides the knife through a sharpening tool with a repeatability of 0.03mm. The knife sharpening is finalized during subsequent deburring and polishing, which is carried out quickly and gently on both sides simultaneously. Optionally users can order the E 50 RT with a fully automated, robot-guided sharpness testing station. The knife goes through a test medium, and the measured sharpness is shown on the display.

CUSTOMER USAGE

680 knives per shift with perfect quality

Along with the very high repeatability and rigidity required in sharpening processes, Stäubli’s proprietary robot encapsulation also proves advantageous in this application. The TX2-90 in the HE (humid environment) version is ideally suited to working with exposure to grinding dust and cooling agents, thanks to its IP65 protection class and internal cable assembly.

The E 50 RT has an output of up to 680 knives per eight-hour shift, depending on the size and shape of the blades. Due to the robot’s high dynamics, this is 1.5 times faster than Knecht’s 4-axis machines. The machine's knife magazine consists of two drums and can hold a total of 576 knives. It can be reloaded while processing, so there is minimal downtime, if any.

To Knecht and its customers in the meat processing industry, however, the extremely high levels of repeatability of the sharpening process are even more important than its throughput capabilities. Knives are perfectly sharpened without losing their individual shape.