Tek bir dakikada hızlı kalıp değişimi için genel otomatik çözümler

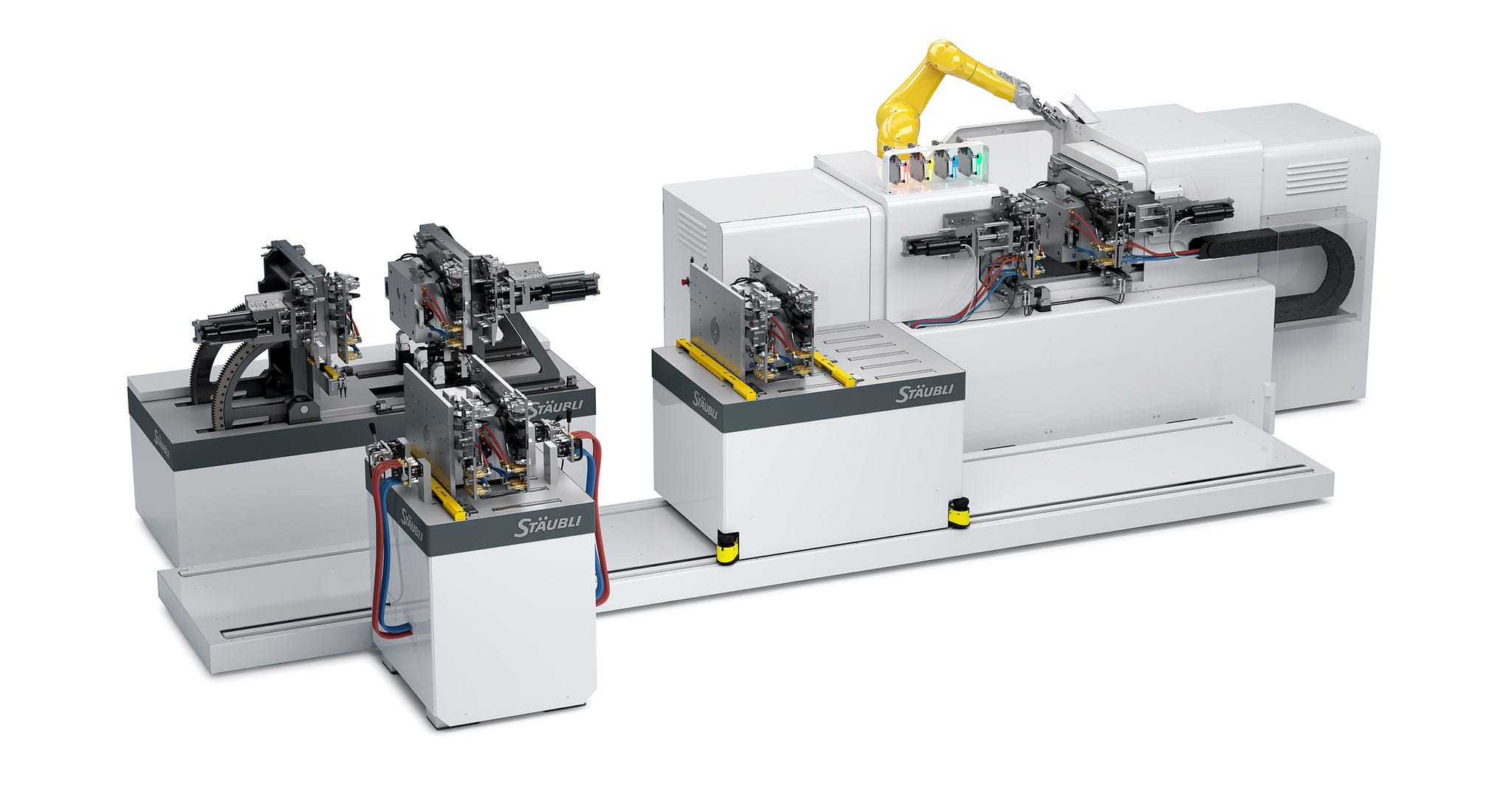

Stäubli'nin süreç otomasyonu, performans ve inovasyona odaklanan QMC (Hızlı Kalıp Değiştirme) çözümleri, SMED (Tek Dakikada Kalıp Değişimi) süreci için çok önemlidir. Kalıp yükleme ve bağlama, enerji bağlantısı ve robotik sistemlerdeki uzmanlığıyla Stäubli, plastik endüstrisinde üretkenliği ve kaliteyi optimize etmek için hedefli veya küresel çözümler sunar.

Kalıp muayenesi

Stäubli iş istasyonları, çok büyük kalıplar üzerinde çalışmayı daha kolay ve güvenli hale getirir.

Parça taşıma

Birden fazla kalıp değişikliğine yönelik artan taleplerle birlikte, rekabetçi kalabilmek için esneklik çok önemlidir. Robotik endüstriyel süreçler için modüler çözümler, robotun aletleri tam otomatik bir şekilde ve zamanında değiştirmesine olanak tanır.

Kalıp transferi ve yükleme

Sabit iş istasyonları ve mekik arabaları: aletlerin, makinelerin ve üretim süreçlerinin özelliklerine göre özelleştirilmiş çözümler.

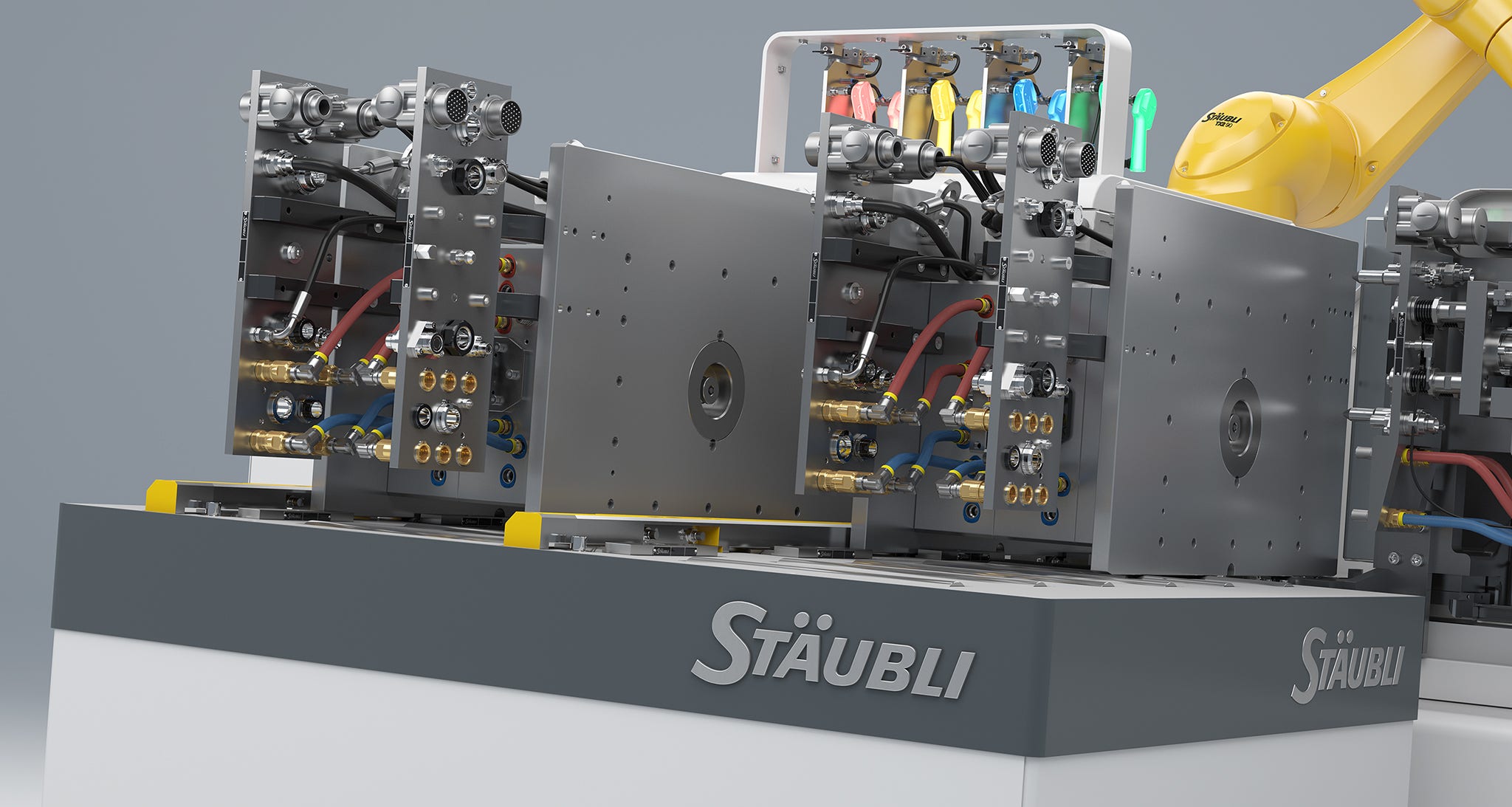

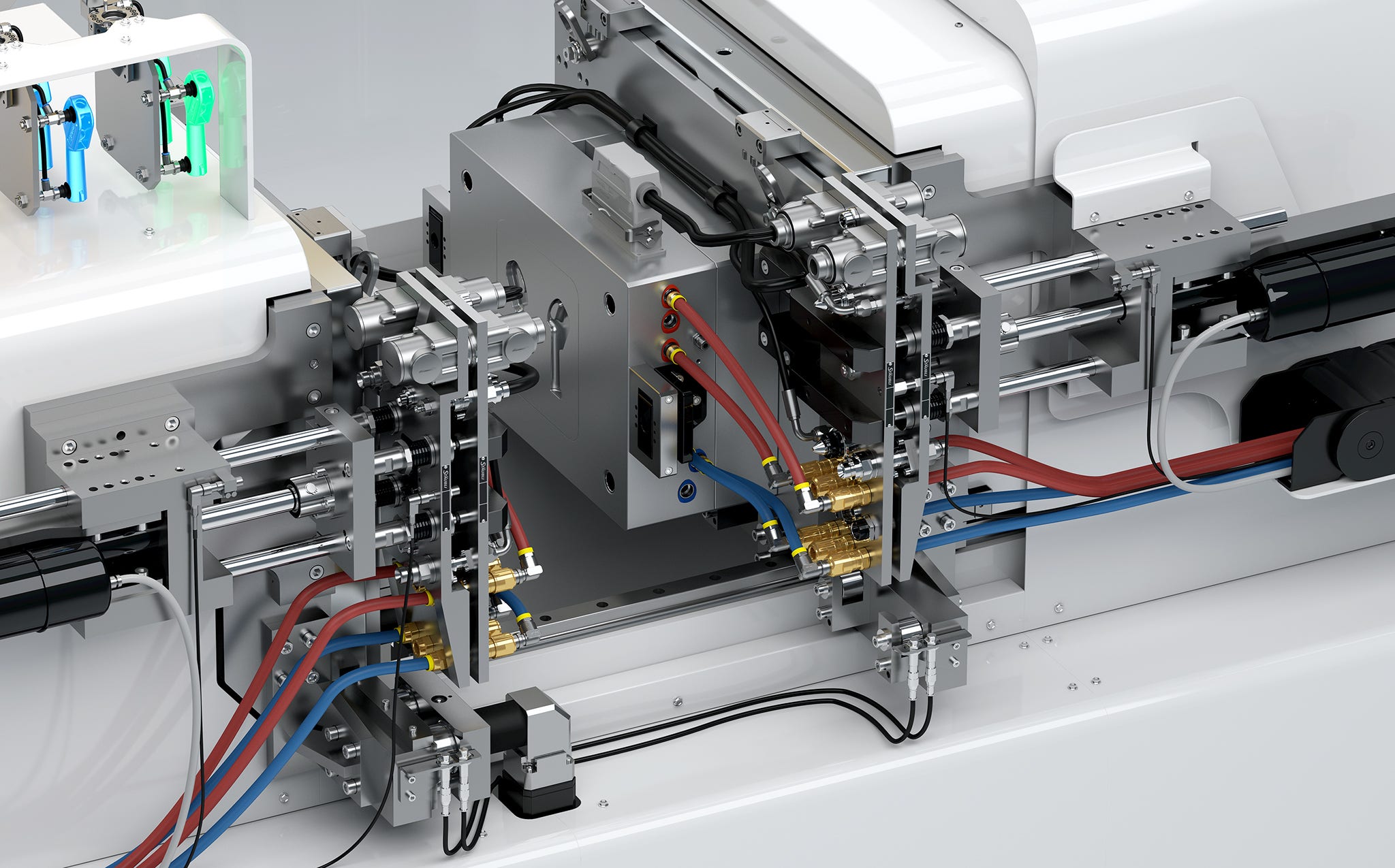

Enerji devrelerinin bağlanması

Kalıpların, hidrolik uygulamaların ve elektrik devrelerinin termal yönetimi için hızlı bağlantı elemanları ve merkezi bağlantılar.

Kalıp sıkma

Mekanik, hidrolik veya manyetik: Size uygun çözümü garanti eden üç mevcut Staubli bağlama teknolojisi.

Kalıp ön ısıtma

Ön ısıtma istasyonları, mevcut kalıp hala kullanımdayken bir sonraki kalıbın çalışma sıcaklığına ulaşmasını sağlar. Bu, kalıp değişimleri arasındaki duruş süresini minimuma indirir.

Plastik işleme uygulamaları

Stäubli'nin plastik endüstrisine yönelik çözümleri, kalıp değiştirme sürecinin her kritik aşamasını ele alarak güvenlik, hız ve verimlilik sağlar. Bu uygulamalar, kalıp bağlantısı ve bağlamadan robotik takım değiştiriciler aracılığıyla yükleme, denetim ve otomasyona kadar uzanır ve üreticilerin tutarlı kaliteyi korurken üretkenliği artırmalarına yardımcı olur.

- Kalıp bağlantısı

- Kalıp sıkma

- Kalıp yükleme

- Kalıp muayenesi

- Robotlar ve robotik takım değiştiriciler

Plastik üretim zincirinin her adımını optimize etmek

Stäubli, SMED metodolojisi ile değişim sürelerinin azaltılmasından yüksek performanslı robotlarla üretimin otomatikleştirilmesine kadar plastik üreticilerini dönüşüm yolculuklarının her aşamasında destekliyor. Akışkan konnektörleri ve robotik alanındaki bölümler arası uzmanlığımızın daha akıllı, daha çevik ve daha rekabetçi üretim ortamları oluşturmaya nasıl yardımcı olduğunu keşfedin.

Plastik endüstrisindeki kapsamlı çözüm yelpazemizi keşfedin

Sezgisel Ürün Bulucumuz ile plastik işleme ihtiyaçlarınız için en uygun Stäubli çözümlerini hızlı bir şekilde belirleyin. İster kalıp bağlama sistemleri, ister hızlı kalıp konektörleri veya robotik takım değiştiriciler arıyor olun, bu araç kapsamlı portföyümüzde gezinmenize ve özel uygulama gereksinimlerinize göre uyarlanmış doğru ürünleri bulmanıza yardımcı olur.

Neden Stäubli'yi seçmelisiniz?

Endüstrinin gelişen taleplerini karşılamak için inovasyondan daha fazlasına ihtiyacınız var: kanıtlanmış, verimli çözümlere ihtiyacınız var. Bağlantı teknolojilerinde küresel bir lider olan Stäubli, plastik üreticilerinin arıza süresini azaltmasına, güvenliği artırmasına ve Endüstri 4.0'ı benimsemesine yardımcı oluyor. Uzmanlarımızın manyetik kelepçeleme, merkezi bağlantılar ve daha fazlasıyla ilgili temel zorlukları nasıl ele aldığını görmek için üç kısa videoyu izleyin.

Müşterilerimize nasıl yardımcı olduğumuzu öğrenin

Müşterilerimizin başarı hikayeleri

Stäubli, üretkenliği ve verimliliği artıran yenilikçi ve güvenilir çözümler sunarak plastik endüstrisindeki müşteri beklentilerini sürekli olarak karşılamaktadır. Müşterilerimiz, benzersiz uzmanlığımız ve kaliteye olan bağlılığımız için bize güvenerek uzun vadeli başarılarını ve memnuniyetlerini garanti eder. Başarı hikayelerimizi keşfedin!

Uzmanımızla iletişime geçin!

Plastik üretim sürecindeki hızlı bağlantı sistemleri hakkında ayrıntılı bilgi için uzmanımızla iletişime geçin.

Belgeleri edinin

Özel içerik için kaydolun!

Stäubli yenilikleriyle bir adım önde olun, Stäubli güncellemeleri için kaydolun!