- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

End-of-Arm-Tooling (EOAT): Indispensable to robotics

1. Introduction

Defining End-of-Arm-Tooling

In robotics, end-of-arm tools refer to equipment attached to the robot's arm that performs physical work or interacts with the environment. Typical examples of such tools are gripper systems, vacuum tools, welding tools, or similar process equipment.

Modern robotics groups tools like this under the umbrella term of "End-of-Arm-Tooling" (EOAT). End-of-arm tooling is crucial in the manufacturing industry since it contributes heavily to the automation of manufacturing processes. EOAT makes it possible to exploit the full potential of cutting-edge robotics.

The significance of EOAT in industry

Robotics has been continuously evolving in recent years. The stereotype of the bulky industrial robot that "does the heavy lifting" (of heavy parts, for instance) no longer reflects reality. Modern, high-precision robot systems that can be integrated seamlessly into automated production processes have stepped into their place.

End-of-arm tooling has played a key role in this evolution: Situated at the interface between the robot and the object being manipulated are the tools that actually give the robot its full range of capabilities. Only then is it possible to exploit the full potential of process automation.

This eliminates the need for humans to perform labor-intensive and time-consuming tasks, resulting in increased speed, efficiency, and precision in the entire manufacturing process. By using end-of-arm tools, businesses not only achieve significant cost savings, but the use of robots also reduces the risk of manufacturing defects and workplace accidents.

2. Advantages of robots with End-of-Arm-Tools

In the manufacturing and automation industry, using end-of-arm tools brings far-reaching benefits. Some of these benefits include:

Higher productivity

Robots were originally designed mainly for heavy, dangerous tasks, but in an Industry 4.0 context, their main benefit lies in the massive productivity gains from automated manufacturing processes. The EOAT process devices enjoy another key role here, as the proper tool insert is required to interact physically with the object. End-of-arm tools function precisely, with maximum efficiency and zero error, resulting in much higher productivity at lower cycle times.

Quality standards

EOAT solutions ensure higher quality, especially in the case of repetitive work steps such as gripping, positioning, driving screws, drilling, or welding. Modern industrial robots are capable of working with high precision and zero error. The result: Significantly fewer rejects, which is also a boon for material efficiency and the company's environmental footprint. In addition, robotics also takes a great deal of strain off the shoulders of the quality assurance division.

Lower costs

From a high-level strategic viewpoint, investing in modern end-of-arm tools pays for itself multiple times over, thanks to significant cost savings in the production process. Unlike manual labor, robots aren't just more safe and precise in their work in, they're also much faster. Robotics makes it possible to rebalance personnel resources to more complex tasks, or to reduce personnel costs outright.

3. Different types of End-of-Arm-Tools

End-of-arm tools are also known as robot end effectors. They comprise a wide spectrum of process devices. Besides tools for handling parts, such as grippers or vacuum ends, there are also tools that carry out fully automated manufacturing steps such as drilling, screwing, or welding. End-of-arm tools also include sensors such as collision sensors or torque sensors.

Below, we present some of the most important end-of-arm tools in the area of material handling.

Grippers

Grippers are a classic end-of-arm tool. They are used in numerous automated manufacturing processes. Gripper technology allows for precise picking, transporting, positioning, and assembly of components in manufacturing processes. Small or even very large components can be safely and securely picked up and placed back down. Robot grippers can be customized to the characteristics of the component in question. For example, angular grippers can securely pick up parts that are thicker at the front than at the back; and needle grippers are specially suited for materials that can neither be vacuum-picked or grabbed.

- Parallel grippers

- Angular grippers

- 3-finger grippers

- Needle grippers

- Internal grippers

Parallel grippers are gripper systems with two or more parallel jaws that grasp the object. Parallel grippers are popular mainly for their simple construction and versatile application. This gripper system is a shoe-in for EOAT applications that require a high gripping force.

Angular grippers are capable of gripping components at a defined angle. The jaws of this type of gripper system are not parallel, but instead are angled. This makes it possible to grip components that are slimmer toward the back, or to clamp components.

The 3-finger gripper is able to grip components at three contact points, allowing for especially precise, stable picking, and placing. Round components are one typical reason for using this type of gripper.

Needle grippers are used to securely grip objects that are porous, sensitive, or otherwise difficult to pick using suction. A needle gripper has multiple needles that can extend and retract to hold an object securely. This type of gripper is often used in the textile and electronics industries to handle sensitive materials such as fabric, fiber composite materials, circuit boards, or wires.

Internal grippers are end effectors that can grip and grasp objects from inner surfaces. An internal gripper consists of specialized jaws that open and close, or otherwise uses an expanding element that swells using a medium under pressure. This allows an object to be clamped from the inside while maintaining sufficient contact with the inside surfaces of the object. Internal grippers are often used to pick and move objects with cylindrical or rectangular cavities, such as pipes.

When selecting a suitable gripper, users have access to a wide portfolio of various gripper types. For most typical customer requirements, there is a suitable end-of-arm tool.

Vacuum end effectors

Suction has become an integral part of modern robotics. Like gripper jaws, vacuum suction tips are used mainly for picking and moving objects. Here, one or more channels transmit a suction force that holds the object to the vacuum tip in an airtight seal.

Robot vacuum grippers either have a flat design or feature rubber bellows and are used for a dizzying range of handling tasks. Typical applications are the handling of sheet metal or glass, picking deformable or soft boxes in the packaging industry, or processing foodstuffs.

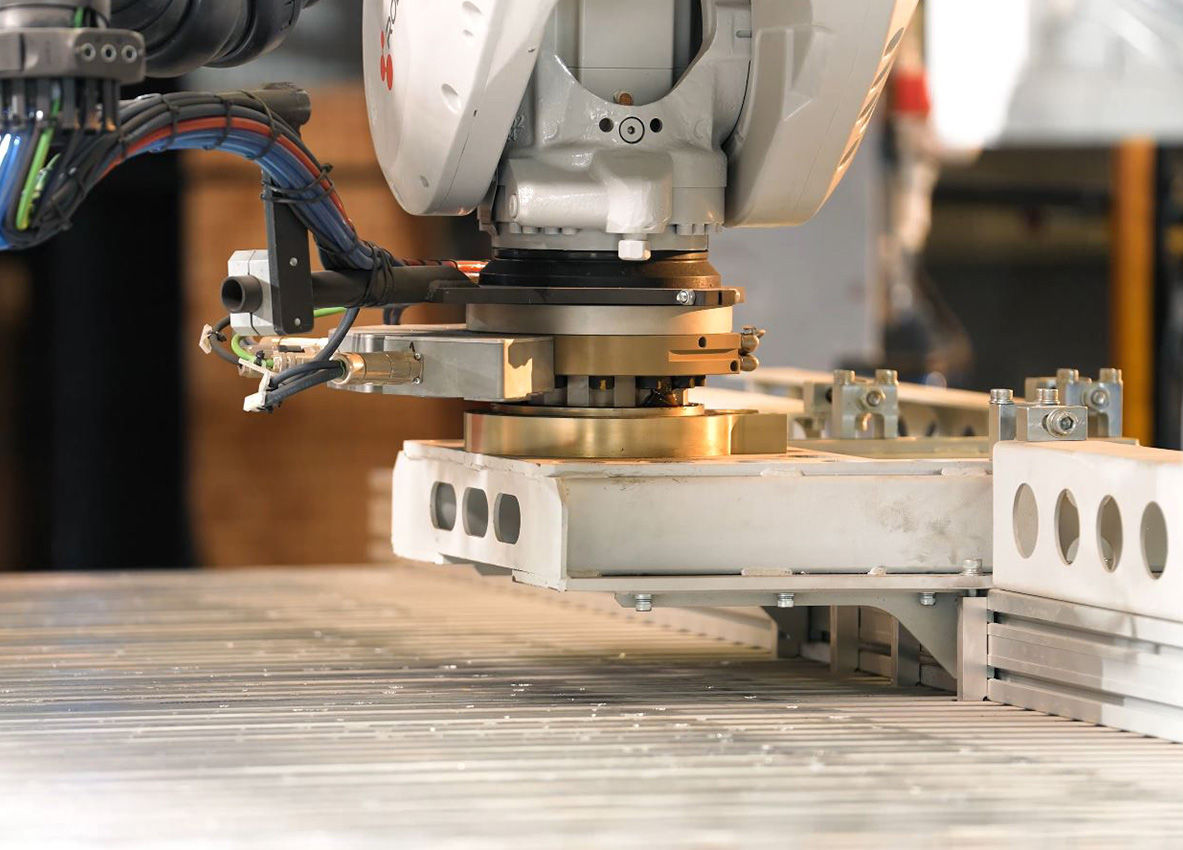

Robotic tool changer systems for robots

Tool changers make it possible to change between a wide array of robot end effectors efficiently. In such a situation, the EOAT tool changer system can either be manual or automatic. Tool changer systems greatly expand the spectrum of applications of robots. Therefore, they are most common in robot applications involving many different tasks.

Tool changers are situated at the interface between the wrist (flange) of the robot and the end effector. For this reason, tool changers must be precisely calibrated to the requirements of both the robot and the tool. What's more, tool changers also transmit electric signals, data, water, compressed air, welding media, and servo force.

- Automatic robotic tool changer systems

- Manual robotic tool changer systems

Automatic Robotic Tool Changers (ATCs) allow for automatic switching between different process end effectors. This makes it possible to increase the degree of automation, boost productivity and reduce personnel costs at the same time. An automatic tool changing system is particularly useful when tools have to be changed frequently during the process.

Angular grippers are capable of gripping components at a defined angle. The jaws of this type of gripper system are not parallel, but instead are angled. This makes it possible to grip components that are slimmer toward the back, or to clamp components.

Welding guns

Robots are used for welding in numerous industries, particularly in the automotive industry. Using EOAT solutions makes it possible to automate most of the welding process, enabling high-quality welds with minimum cycle times. EOAT applications are commonly used for spot welding.

Cameras and sensors

EOAT solutions are suitable for the physical handling of components, inspection, and quality control. Cameras, ultrasound sensors, infra-red sensors, laser scanners, and other such systems are used here to inspect parts.

EOAT for manufacturing processes

End-of-arm tools are also used for subtractive manufacturing, primarily in the metalworking and plastic processing industries. Typical applications include drilling, cutting, deburring, and grinding of components.

4. Challenges when working with EOAT solutions

There are various technical and economic aspects to consider when developing, implementing, and operating end-of-arm tools for robotic systems. These are, in particular, the following challenges:

Design complexity

Designing modern EOAT systems requires a deep understanding of robotics, especially with applications requiring high precision or speed. The end-of-arm tool must be precisely matched to the application while considering specifications for the weight and form of components, for the drive systems and controllers, spatial limitations, and other aspects.

Investment costs

Depending on the application, implementing EOAT solutions can be quite costly. Therefore, before investing in end-of-arm tools, it is advisable to draw up a detailed economic feasibility calculation. The gains in both the top and bottom-lines resulting from efficiency increases and lower personnel requirements must be balanced against the upfront costs and overhead costs of implementing EOAT solutions.

Servicing and maintenance

EOAT systems typically contain many moving parts that experience a natural wearing process. When integrating end-of-arm tools into the manufacturing process, you should therefore try to choose low-wear components that can be quickly replaced when necessary. This will keep servicing and maintenance costs to a minimum.

System integration

The integration of the end-of-arm tool into the robot system and the wider manufacturing environment should be considered as early as the design phase. When doing so, all component systems should be carefully coordinated with one another and compatibility ensured. System integration pertains not only to the physical parameters of the robot arm, tool changer, and EOAT, but also has implications for the specifications of the software and the controller.

Safety aspects

When implementing end-of-arm tools, safety is always the top priority. This is especially true in cobot systems, where people and robots work side by side. In this case, it is necessary to take safety precautions to prevent workplace accidents. These include, for example, sensors for process monitoring and automatically shut-off devices.

Conclusion: More productivity and precision thanks to End-of-Arm-Tools

Thanks to their many benefits, EOAT systems have become a mainstay of the manufacturing industry. Modern robot end effectors not only make it possible to design manufacturing processes with greater precision and efficiency, they also noticeably increase industrial safety and product quality standards. In a globalizing economic environment, EOAT holds the potential to sustainably improve your competitiveness in production.

Implementing versatile, flexible EOAT solutions makes it possible to tune production processes to new requirements quickly, and exploiting the principle of modularity will allow you to make maximally efficient use of available robotic systems. For example, a single robot can complete a wide range of tasks without human intervention, thanks to a suitable tool changer and end-of-arm tools.

Modern robotic systems with EOAT solutions today are showing off their strengths in numerous applications. These include assembly, material handling, feeding and unloading machines, as well as picking, packing, palletizing, welding, and drilling components.

More topics in focus

Our topics serve as your comprehensive resource for understanding the critical role of robot tool changers in enhancing efficiency across a multitude of applications.

Contact us for more information.

Stäubli is a leading technological pioneer in the construction and development of robotic tool-changing systems solutions.

Discover the versatility and efficiency of Stäubli's advanced robotic tool-changing systems by downloading our showcases of innovative solutions.

Success Stories

Find out our solutions and customer testimonials!

-

Volvo Trucks - Automotive

Provide robot tool change systems which meet Volvo’s demanding reliability target. -

Silberhorn - Industrial Machinery

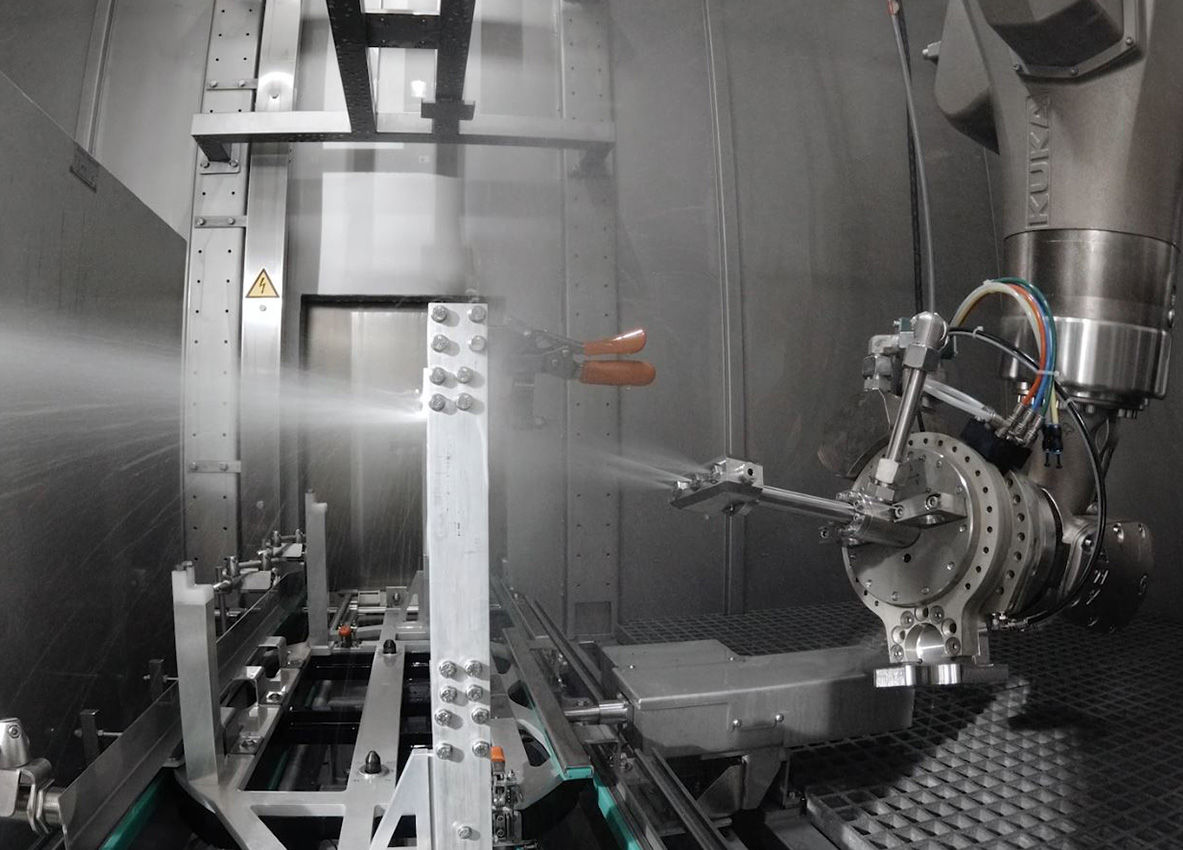

Component cleaning for metalworking in the tightest of spaces - Robot tool change in the wet cell. -

Robinova / Teksan - Industrial Machinery

A field proven solution which saves time, improves robot utilization, and enhances operator safety.