- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

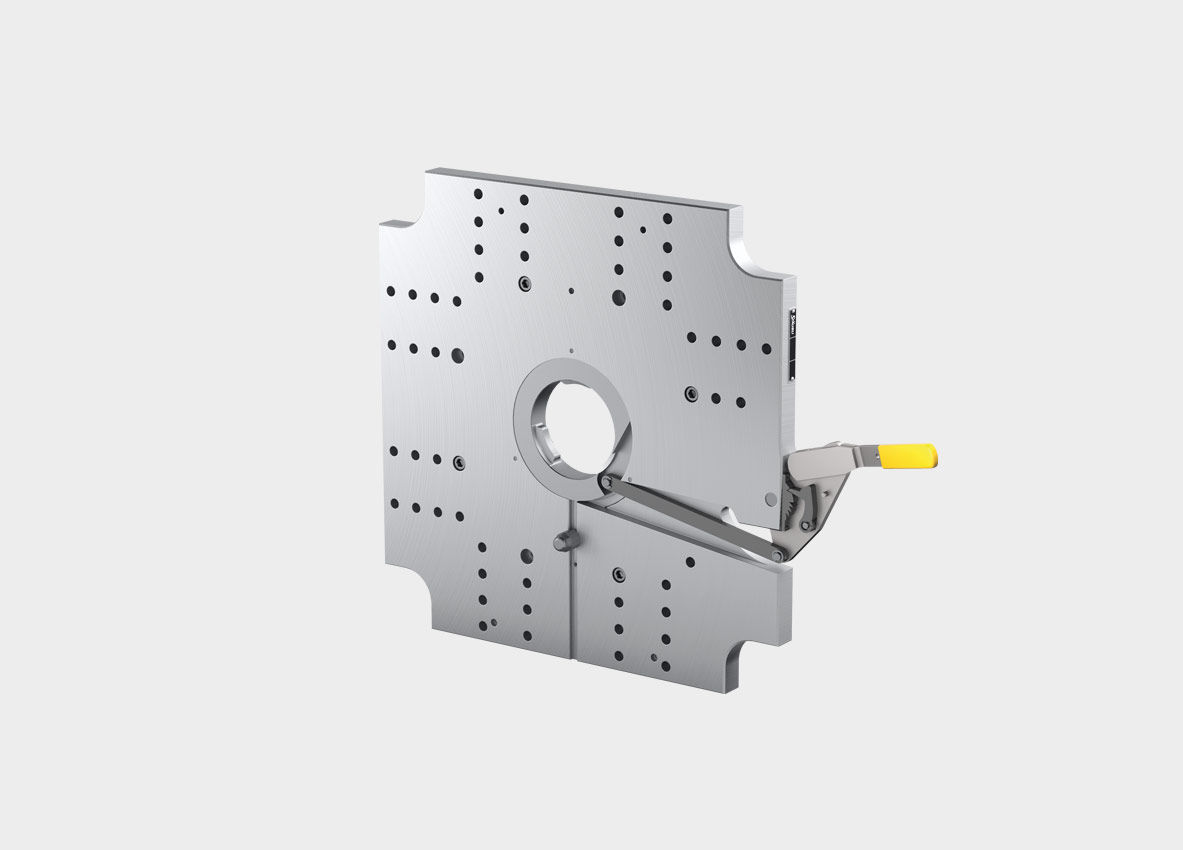

QMC123: Essential & Premium line - 2 solutions fitting distinctive needs

The QMC123 magnetic clamping systems, next generation offers many advantages during quick mold change operations: total security, high efficiency, and optimized profitability. Active safety, interactivity with the operator, and exact measurement of the clamping force are innovative functions made possible by the IMAG technology developed by Stäubli. Thanks to design and many inspections carried out during clamping operations and production, these Stäubli solutions significantly help increase productivity.

APPLICATION

- Plastics industry – mold clamping on injection presses and plastics machinery (50 to +4000 t)

- Designed to speed-up the productivity & reinforce the safety of those who have to change molds frequetly

The QMC123 magnetic clamping systems ranges

Key benefits

- Integration

- Operation

- Profitability

Technical characteristics

| Technical characteristics | Construction | Safety functions |

|

| By integrating the many features enabling anticipation of malfunctions, the QMC solution creates a reduction in machine downtime.

|

- Increase safety, reliability and productivity

Sign up for exclusive content

Get the latest solutions from Stäubli delivered right to your inbox!

RELATED PRODUCTS

This might interest you

-

Mechanical clamping

Simple and safe: mechanical bayonet clamping system for safe tool clamping in one easy movement. -

Hydraulic clamping

Compact and robust: hydraulic clamping system for automated tool change under harsh operating conditions. -

Plastics process

Quick couplings for temperature control and hydraulic circuits, mold loading and clamping systems for QMC applications.