- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

Active Warp Control 2.0 - Advanced automatic warp thread control system

Optical and non-contact state of the art technology

The 100% controlled identification and handling of warp yarns to achieve the highest quality and reliability in warp processing – namely during automatic drawing-in – is the purpose of Stäubli’s advanced technology “Active Warp Control 2.0” (AWC 2.0).

The central aspect of AWC 2.0 is the optical, non-contact recognition and measurement of yarn characteristics by cameras. Updated high-performance processors analyze the images and deliver precise data at millisecond intervals on the condition of the warp yarns to be processed. This data is compared with the target data, both from the programmed draw-in repeat and the weaving mill’s empirical values, to detect errors with enhanced certainty.

Drawing-in with SAFIR systems featuring Stäubli AWC 2.0 ensures weavers profit from a faultlessly drawn-in harness and maximum productivity in the weaving process.

Discover SAFIR's range of automatic drawing-in machines

-

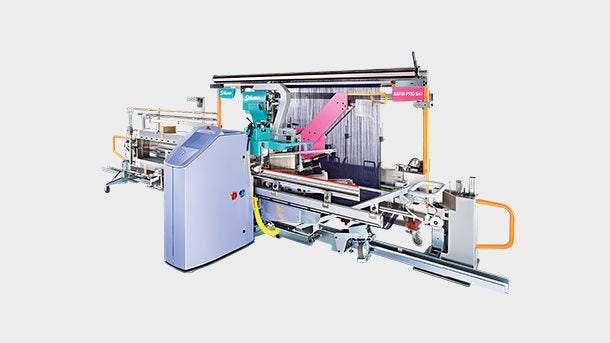

SAFIR PRO S47 high-speed drawing-in machine

The SAFIR PRO S47 high-speed automatic drawing-in machine is the ideal solution for mills producing a variety of standard applications. -

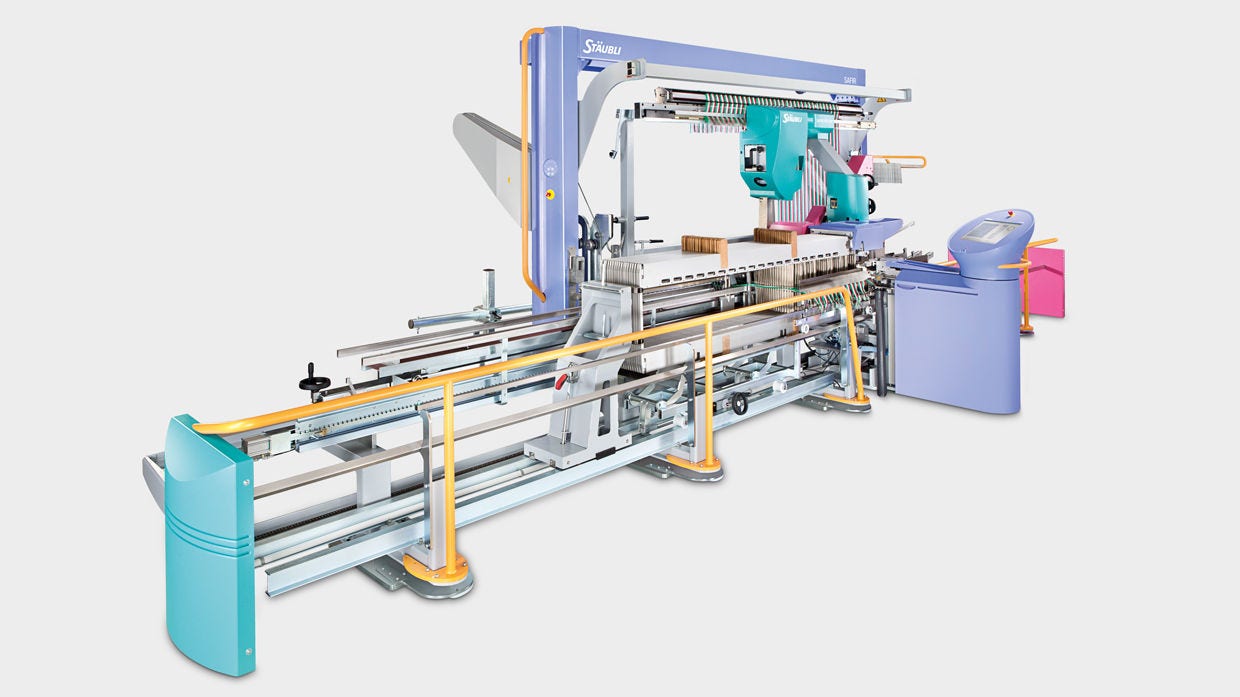

SAFIR PRO S67 high-speed drawing-in machine

The SAFIR PRO S67 high-speed automatic drawing-in machine is designed for universal use in producing various fabric types of medium complexity. -

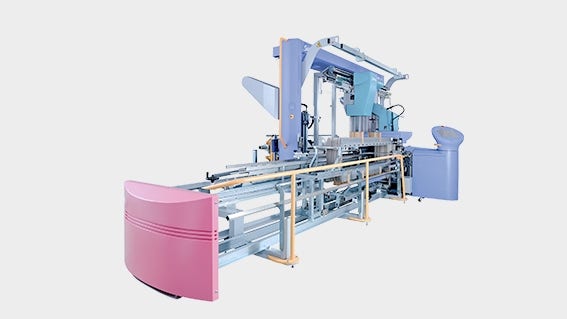

SAFIR S80 drawing-in machine

The SAFIR S80 automatic drawing-in machine is the perfect solution for manufacturing complex fabrics woven with 1 or 2 warp beams.