- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

Payload up to 35 kg

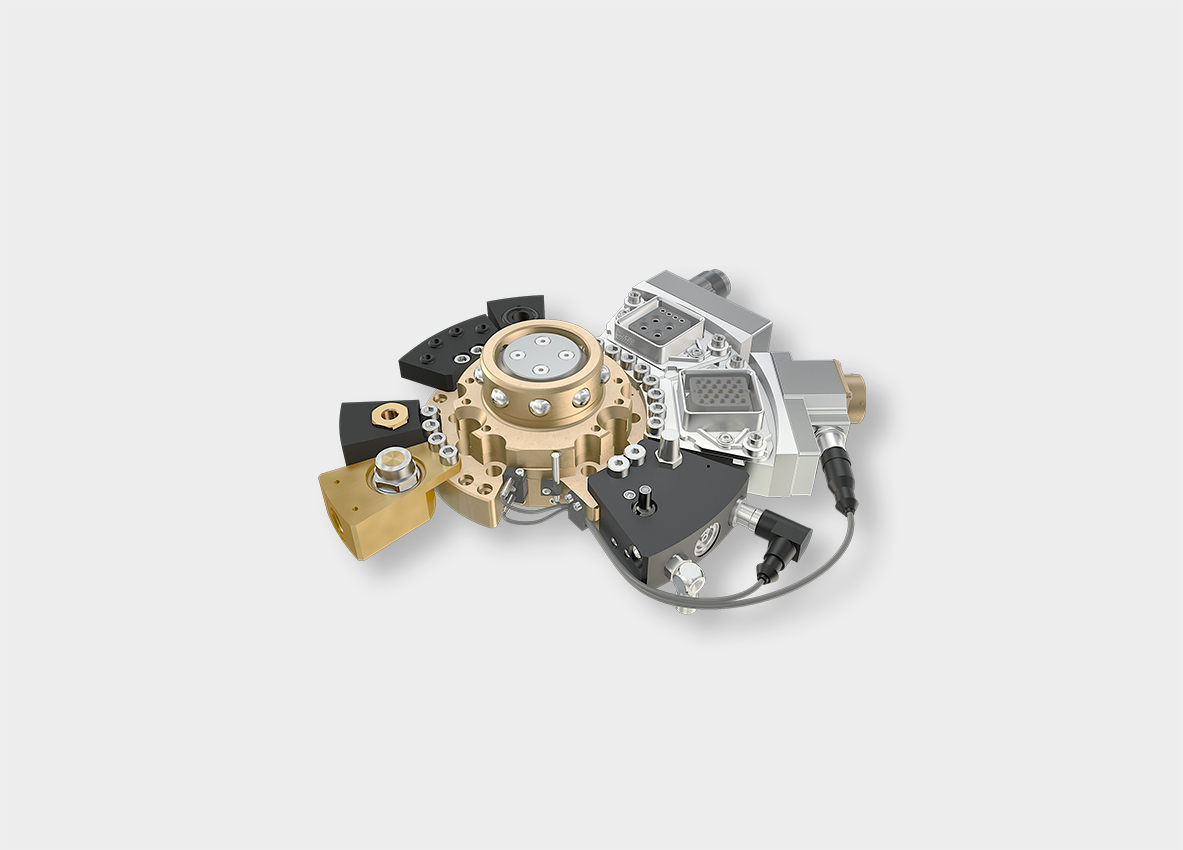

Robotic tool changer MPS 035

The MPS 035 is a highly versatile robotic tool changing system designed for small payload applications. This mid-range tool changer has a payload capacity of up to 35 kg and a compact, modular design that makes it easy to adapt to different media, data and power transfer requirements.

The system offers impressive precision and repeatability, with a repeatability of +/- 0.0015 mm and the ability to handle maximum static and dynamic moments of up to 90 Nm and 319 Nm, respectively. The robot adapter flange features an ISO 9409-1-50-4-M6 pitch diameter, making it compatible with a wide range of robots and small payload applications.

The MPS 035 is specifically designed to operate in harsh environments with an operating pressure range of 0.45 - 1.0 MPa and an operating temperature range of 0 °C to +50 °C. This rugged tool changer is an excellent solution for those looking for a small system with the precision, versatility and reliability to handle small payloads with ease.

APPLICATION

- Automotive manufacturing

- Electronics manufacturing

- Food and beverage production

- Medical device manufacturing

- Aerospace manufacturing

- All types of assembly lines and material handling

Repatibility:

+/- 0.0015 mm

Payload:

up to 35 kg

Max. static moment:

80 Nm

Modul places:

6

Robotic tool changers - modular solutions for every requirement

Whether your projects have individual and comprehensive requirements or need a fast solution, Stäubli's range of robotic tool changers can quickly meet all complex demands thanks to the modular product concept.

Technical specifications

| MPS 035 | |

| Payload | 35 kg |

| Max. static moment (Mx/My) | 80 Nm |

| Max. static moment (Mz) | 80 Nm |

| Max. dynamic moment (Mx/My) | 280 Nm |

| Max. dynamic moment (Mz) | 280 Nm |

| Operating pressure | 0.45 - 1.0 MPa |

| Operating temperature | 0 °C - +50 °C |

| Repeatability | +/- 0.0015 mm |

| Height (coupled) | 46 mm |

| Pitch circle diameter (PCD) robot adapter flange | ISO 9409-1-50-4-M6 |

| Module places | 6 |

MODULES AND ACCESSORIES

- Transmission Modules

- Tool stand

- Teaching aid

- Safety+

Transmission Modules

- Pneumatic & vacuum module FTM

- Pneumatic module ROK

- Ground Pin Module

- Tool coding module

- Electric module for signal and data transmission M8/M12

- Giga module

- RFID module

Tool stand

- Flexibility: With the single system components, your own individual storage solutions can be compiled and also easily integrated into existing systems.

- Modularity: Choose between preconfigured complete systems or single modules that can be used directly with standard profile solutions.

- Longevity: The floating bearing in the upper part of the system ensures that the tool is optimally held in the drop-off position. The load on the components is minimized.

- Economical: One tool storage system that can be used as a vertical or 90 ° rotated solution offers a wide range of possible uses.

- Process reliability: A mechanical fixation with adjustable retention force enables additional securing of the dropped -off tools. The system can optionally be expanded with integrated sensors for status indication.

Teaching aid

- Simple installation of programming support with a click function

- Quick and easy determination of coupling position

- Exact positioning for quick and fault-free docking processes and a long service life

- No additional software necessary

Safety+

System for personal and system safety.