- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

Save Time, Think Performance - Quick Connectors for Aerospace & Defense

Stäubli has been a trusted partner to the Aerospace & Defense industry for over 40 years, collaborating on major international projects. Recognized for its expertise, Stäubli provides connection solutions that meet the stringent requirements of this critical sector. The company excels in delivering exceptionally safe, clean, lightweight and compact quick connectors for applications such as thermal management, air conditioning, breathing air, compressed air, fuel and hydraulics.

Stäubli offers innovative solutions for all types of systems: radars, armored vehicles, directed energy, aircrafts, submarines, UAVs, drones, ships, as well as spacecrafts. Thanks to its advanced technologies and commitment to quality, Stäubli remains a key player in the Aerospace and Defense sector, reliably and efficiently meeting the needs of its customers.

Solutions for Aerospace & Defense applications

- Air conditioning - Electronic liquid cooling

- Fuel & airport

- Power packs & test benches

- Medical breathing air

- Fuel cell & batteries

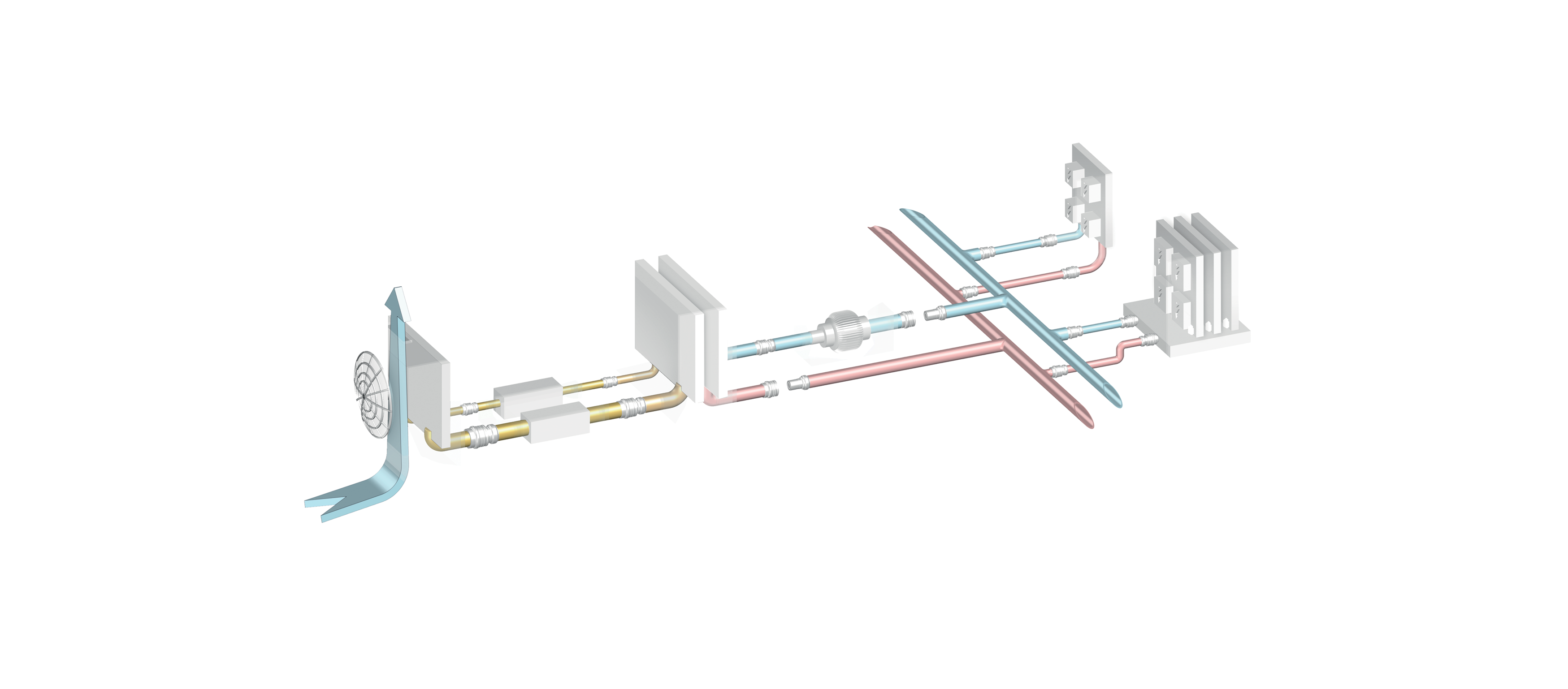

Split system

Quick-release couplings on air-conditioning components (compressor, condenser, evaporator), enable assembly and disassembly of the system without draining and refilling the refrigerant circuit.

Refrigerant – fill & drain

In the commissioning phase or for deeper maintenance processes, the line must be completely drained and refilled. Stäubli connectors facilitate this process quickly and reliably.

Liquid cooling – main supply

Stäubli high-flow, flat-face couplings deliver maximum reliability, while pressure-relief systems ensure safety.

Liquid cooling – cold plate connection

Electronic components are increasingly cooled by liquid-filled cold plates. Bayonet locking systems provides a high degree of ergonomic and safety.

Blind mate connection of individual cold plates

For compactness reasons cold plates must be racked in a chassis. CGO and CGD couplings allow connection without spillage and level out different misalignments.

Fuel logistics

From the refinery to the consumer, fuel logistic requires many connection points. Whether STANAG or specific dedicated profiles, Stäubli assures safe and non-spill connections.

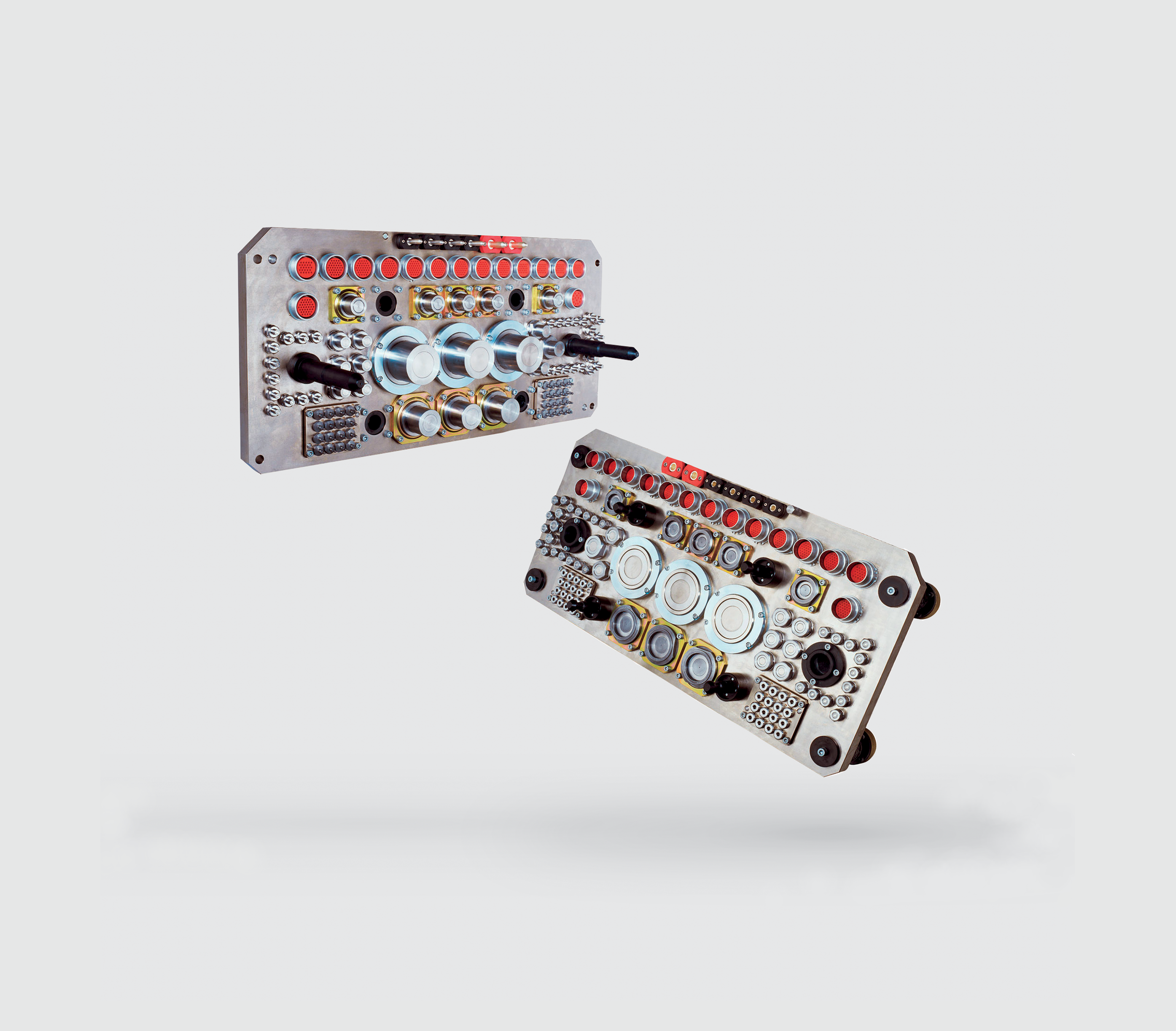

Testing

Quick connections are the key to completing testing processes in the best conditions of safety and quality.

Airport

Airport processes demand flexibility. Quick-release couplings from Stäubli deliver optimum efficiency in modular systems.

Filling coupling for deicing process

Extreme temperatures and humidity conditions require the aircrafts to be preapared with a spray of glycol on their surface. Glycol logistic can be simplified with the use of quick release couplings.

Fuel lines and coolant

Fuel connection from tank to engine and everything in between. Coolant and heating lines: Quick, secure and non-spill connections from engine to radiator and heating system.

Hydraulic lines

For braking and steering. High or low pressure, vibrations, shocks and/or pressure picks, Stäubli connectors are compliant to those difficult environments.

Test benches

Stäubli test-bench connectors eliminate the risk of misconnection, improve quality, and reduce process-preparation time.

Refrigerant – fill & drain

In the commissioning phase or for deeper maintenance processes, the line must be completely drained and refilled. Stäubli connectors facilitate this process quickly and reliably.

Coolant line

Quick change of the radiater for replacement or access to other parts of the engine. Connection to the heater inside the cabin, all without purging the line.

Split system

Quick-release couplings on air-conditioning components (compressor, condenser, evaporator), enable assembly and disassembly of the system without draining and refilling the refrigerant circuit.

Oxygen low pressure

The oxygen supply at different locations of an hospital must be deployed rapidely but with caution, the connection must avoid pollution in the line. Flat face coupling technology complies with this requirement.

Logistics and transportation

Stäubli connectors ensure high-pressure bottles are connected safely during filling and use.

Breathing air

Emergency situations or harsh environments require human operation and an autonomous breathing air system must be used.

Oxygen bottle filling

High pressure filling is a delicate operation due to the adiabatic pressure. A specifc coupling must be used for the quick connection of the bottles to the high pressure supply line.

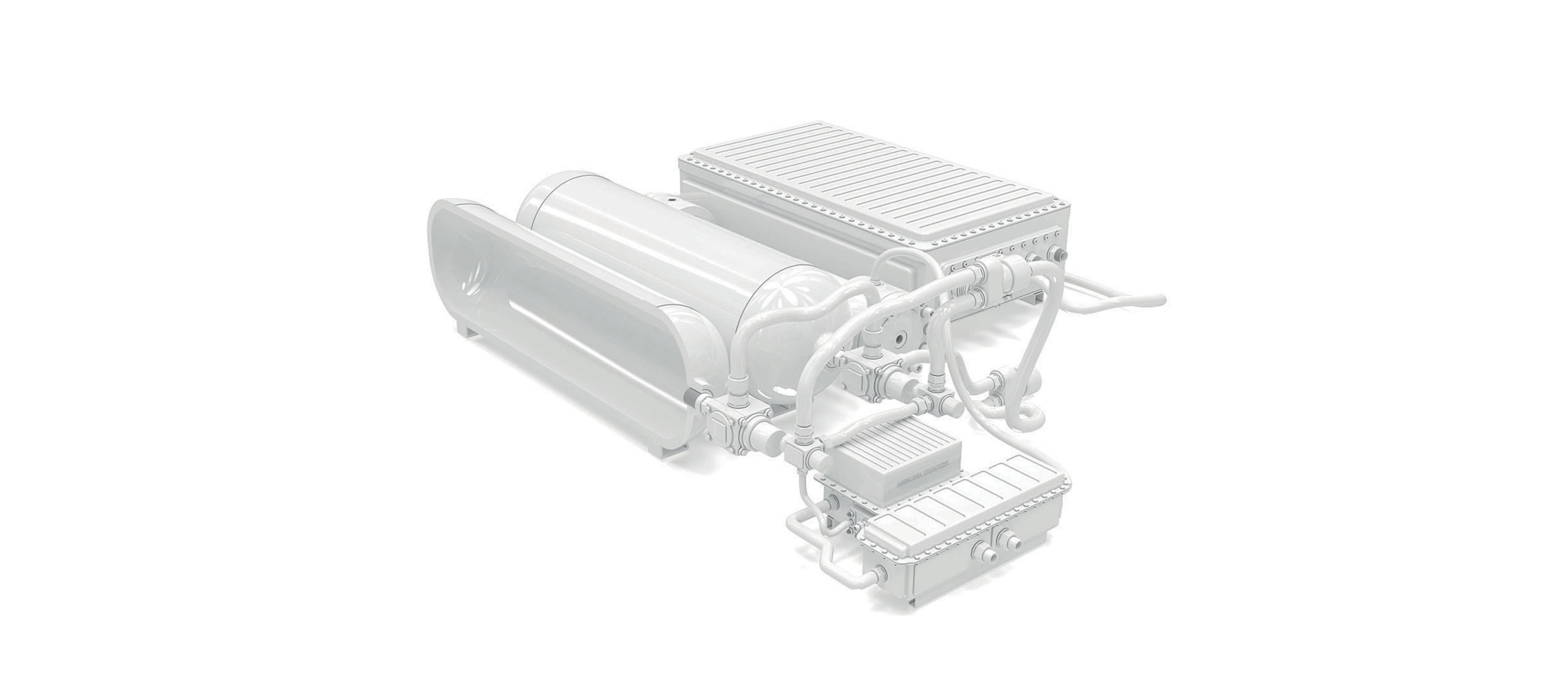

Cooling

In the fuel cell and further in the batteries, heat is generated and must be evacuated. Liquid cooling lines are embedded and so the requested time for the maintenance process can be reduced with appropriate QRCs.

Hydrogen filling

High pressure hydrogen bottles can be rapidely connected to the supply line. After the filling process, the pressure is released for disconnection

Low pressure hydrogen line

After expansion, the low pressure hydrogen is led to the fuel cell. The maintenance of the sytem is simplified by the connection with QRCs.

High pressure hydrogen line

From the high pressure bottle to the pressure reducer, the line can be connected and disconneted with the dedicated coupling

Product finder