- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

A complete program from sizing to weaving

Efficient warp and style changes are decisive factors for flexibility and productivity in the weaving mill. Stäubli offers advanced system solutions for reading in of warps at sizing machines, automatic drawing-in, warp leasing, and warp tying, as well as supporting means for quick style changes on the weaving machine.

Stäubli’s weaving preparation systems can be used in all weaving mills and with all types of weaving machines. By working closely with customers as well as manufacturers of weaving machines and transport equipment, we have optimised and adapted our systems to meet a wide variety of requirements

EASY INTEGRATION INTO EXISITING PROCESSES

Stäubli automation solutions are flexible in terms of application, layout, and space requirements, meeting the requirements of different types of organization in the weaving preparation hall.

To optimize style changes, weavers can easily adapt or add options to SAFIR automatic drawing-in machines, e.g. Active Warp Control (AWC) options for yarn sorting and yarn controlling and Initial Condition Settings (ICS) options for fancy, hairy, or technical yarns. ICS expands AWC with additional features for specific yarn types, enabling even faster start-up after style changes.

All machines are designed to be user friendly, and mill personnel can be quickly trained to efficiently operate the machinery and systems.

MATERIAL FLOW

Find the best solution for your need

Reset filterDiscover complete range of weaving preparation machinery

-

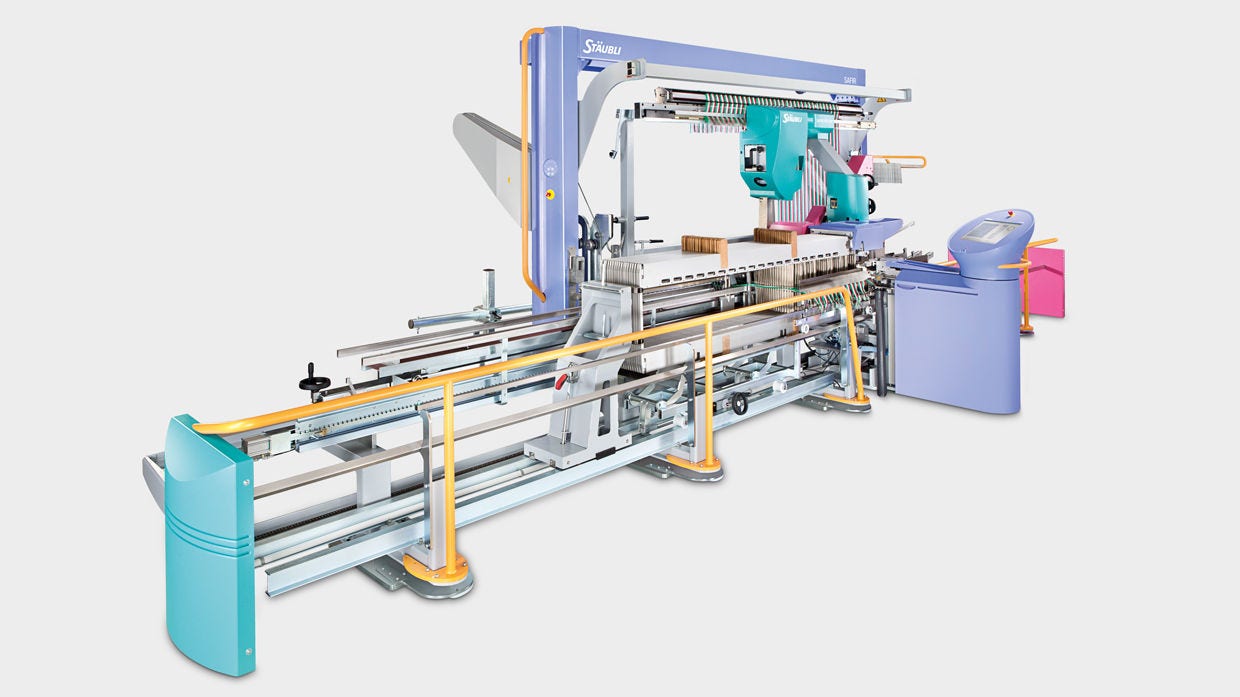

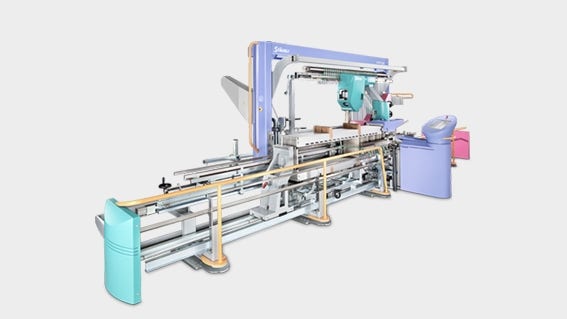

SAFIR PRO S67 high-speed drawing-in machine

The SAFIR PRO S67 high-speed automatic drawing-in machine is designed for universal use in producing various fabric types of medium complexity. -

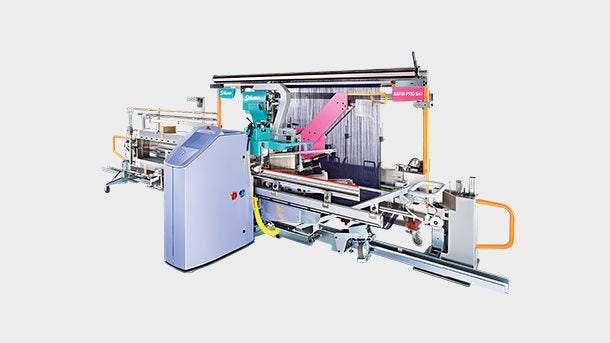

SAFIR PRO S47 high-speed drawing-in machine

The SAFIR PRO S47 high-speed automatic drawing-in machine is the ideal solution for mills producing a variety of standard applications. -

SAFIR S32 drawing-in machine

The SAFIR S32 automatic drawing-in machine is perfect for weaving mills that process filament yarns. -

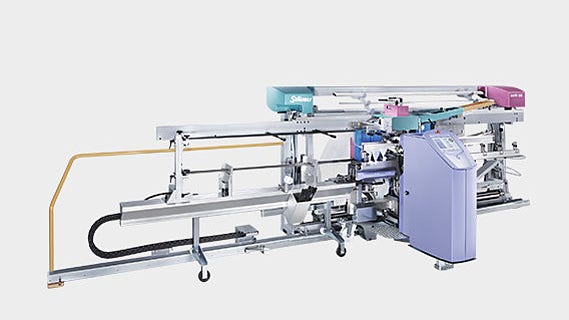

SAFIR S40 drawing-in machine

The SAFIR S40 automatic drawing-in machine is the ideal solution for mills producing a variety of standard applications. -

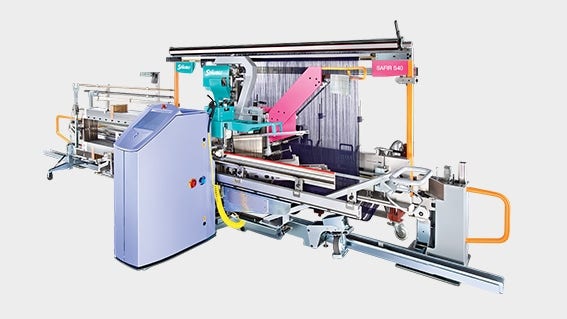

SAFIR S60 drawing-in machine

The SAFIR S60 automatic drawing-in machine is designed for universal use in producing various fabric types of medium complexity. -

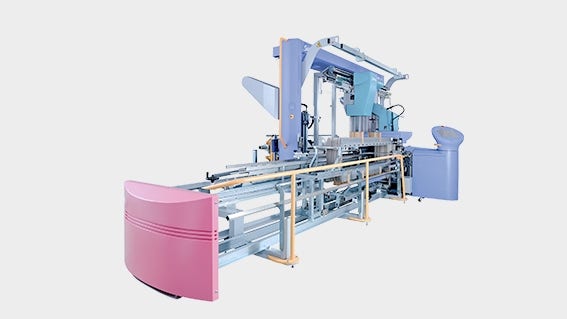

SAFIR S80 drawing-in machine

The SAFIR S80 automatic drawing-in machine is the perfect solution for manufacturing complex fabrics woven with 1 or 2 warp beams. -

TIEPRO warp tying machine

The TIEPRO warp tying machine is dedicated to operating standard yarn types. -

TOPMATIC warp tying machine

The TOPMATIC warp tying machine supports operating versatile and finest yarn types. -

MAGMA warp tying machine

The MAGMA warp tying machine is the ideal solution for coarse and technical yarn types. -

TPF warp tying frame

The TPF tying frame offers easy warp sheet preparation. -

OPAL multi-layer leasing machine

The OPAL multi-layer leasing machine draws in a 1:1 lease into warps for an optimized drawing-in or tying process. -

UNI-LINK

UNI-LINK components help optimize processes between the warp beam stock and weaving machine. -

BEAMPRO reading-in machine

The BEAMPRO reading-in machine perfectly assembles directly on the sizing machine the sheet layers of beam dyed multicoloured warps.

Related success stories

- Slide 1

- Slide 3