SUCCESS STORY

“Superclean” robots for wafer handling

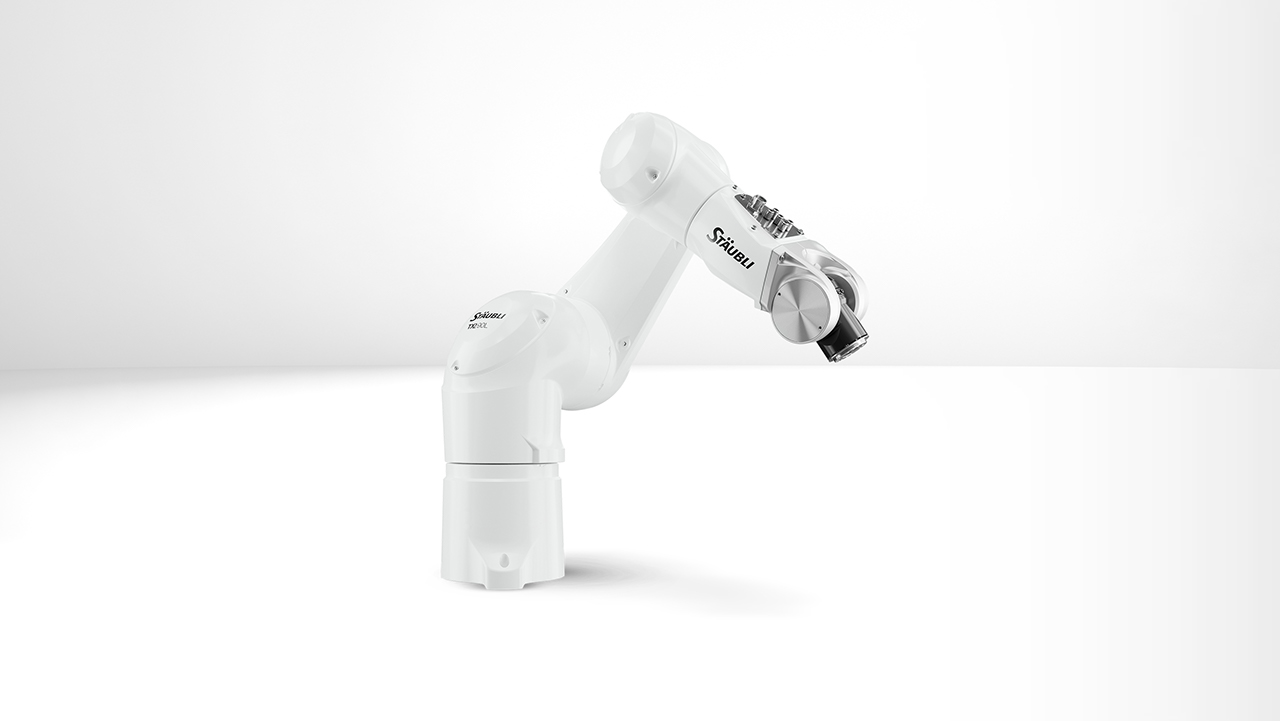

Wafer handling in Class 1 cleanrooms places particularly high demands on particle control, process reliability, and dependability. PTW SpinTec, based in Villach, Austria, relies on a Stäubli TX2-60 robot in SCR design for its various handling processes.

CUSTOMER BENEFITS

- Non-contact wafer handling with Bernoulli gripper

- High positioning accuracy

- ISO 1 – highest cleanliness class

- Flexibility thanks to automatic tool change system

Austrian company PTW SpinTec is known worldwide for its high-quality single-wafer wet etching and cleaning systems. In these high-end systems, Stäubli TX2-60 six-axis SCR, i.e., Super Cleanroom robots, handle the wafers. This entails the high-precision robot removing a wafer from the cassette and inserting it into the system’s processing chamber. Due to the highly sensitive handling involved, this is done in a fully contactless manner using a Bernoulli gripper.

The wafer is etched, cleaned, and dried in various processing chambers, and then removed again by the robot and deposited into the designated wafer slot. The robots work in a Class 1 cleanroom, and the positioning accuracy required is in the hundredth of a millimeter range, making this an extremely demanding application. What's more, because the systems can perform different cleaning and etching processes on different wafer sizes, the robots must also be flexible. Thus, automatic gripper changes are also required.

- Teaser

- Teaser

- Teaser