Chinese know-how combined with Stäubli expertise

Luthai Textile Co. Ltd is a renowned Chinese manufacturer of high-quality yarn-dyed shirt fabrics. The company was founded in 1988. With 25,000 employees, Luthai operates the world’s largest production facility for shirt fabrics, supplying world-famous brands such as Burberry, Calvin Klein, Gucci, and Uniqlo.

Luthai produces over 210 million meters of yarn-dyed fabrics and more than 85 million meters of printed and dyed fabrics, making over 20,000 different variations and designs of shirt fabrics every year. Supplying fabric for over 30 million shirts annually, the company is one of the world’s largest producers of shirt fabrics.

The challenge

Luthai exports nearly 80 percent of its annual production to over 30 countries including the USA, Japan, Germany, Italy, and Spain. As part of the Chinese textile industry, the company contributes to the production of 50 million tons of textile per year (Chinese market), representing 54 percent of the global textile market, according to the Textile Development Report. But even this giant in the textile world faces challenges due to rising personnel costs and the demand for high flexibility. Chinese mills are investing more and more in automated production systems in order to meet these challenges.

Customer benefits

- High degree of flexibility in weaving preparation and weaving

- Quick style change

- High-quality and efficiency in production

- Extensive services and experiences

The solution

The challenges can be mastered thanks to Stäubli’s high-speed and highly accurate leasing machines, warp drawing-in machines, and warp typing machines, improving the quality of the yarn-dyed shirt fabrics. Additionally, Stäubli’s comprehensive product range and its extensive experience and technical know-how help Luthai produce more efficiently and save costs. Stäubli has built up a strong relationship with this company over the past 15 years. Today, Luthai operates over 3,700 Stäubli machines.

What does the customer say?

"Stäubli meets our high standards and requirements, both in terms of technology, and service, and helps us to keep moving forward and to achieve our vision of Luthai as a world first-class and Century-old company."

Fangshui Wang, Deputy General Manager and Chief Engineer of Luthai Textile Co. Ltd

Product solution for this type of application

-

SX PRO Jacquard machine

Electronic Jacquard machine is ideal for weaving flat fabrics, terry cloth and technical fabrics on all types of air-jet, rapier and water-jet machines, up to 2,688 hooks. -

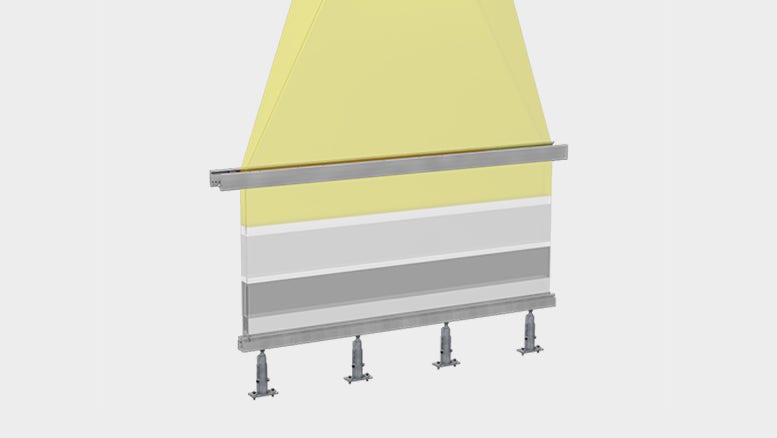

Jacquard Harnesses

Stäubli high quality Jacquard harnesses and Jacquard harness accessories make the perfect link between the Jacquard machine and the warp threads of the weaving machine. -

Rotary dobby series S3000

High-speed electronically controlled rotary dobbies for all types of patterned fabrics in water-jet, air-jet or rapier weaving machines depends on the application.

Stäubli success stories

-

Luxury apparel – Denis & Fils

Denis & Fils, a prestigious weaving company specializing in textiles for women's wear and leading French fashion brands, shares why Stäubli's SX PRO is an essential part of its success. -

Home textile – Penedo

Household and hotel textile manufacturer benefits from great flexibility offered by a large number of hooks in Stäubli Jacquard machines. -

Eco-responsible textiles - Les Tissages de Charlieu

Find out how the SX PRO Jacquard Machine supports Les Tissages de Charlieu in their mission to prove the effectiveness and profitability of sustainable development in textile production.