photovoltaics

PV cell manufacturing

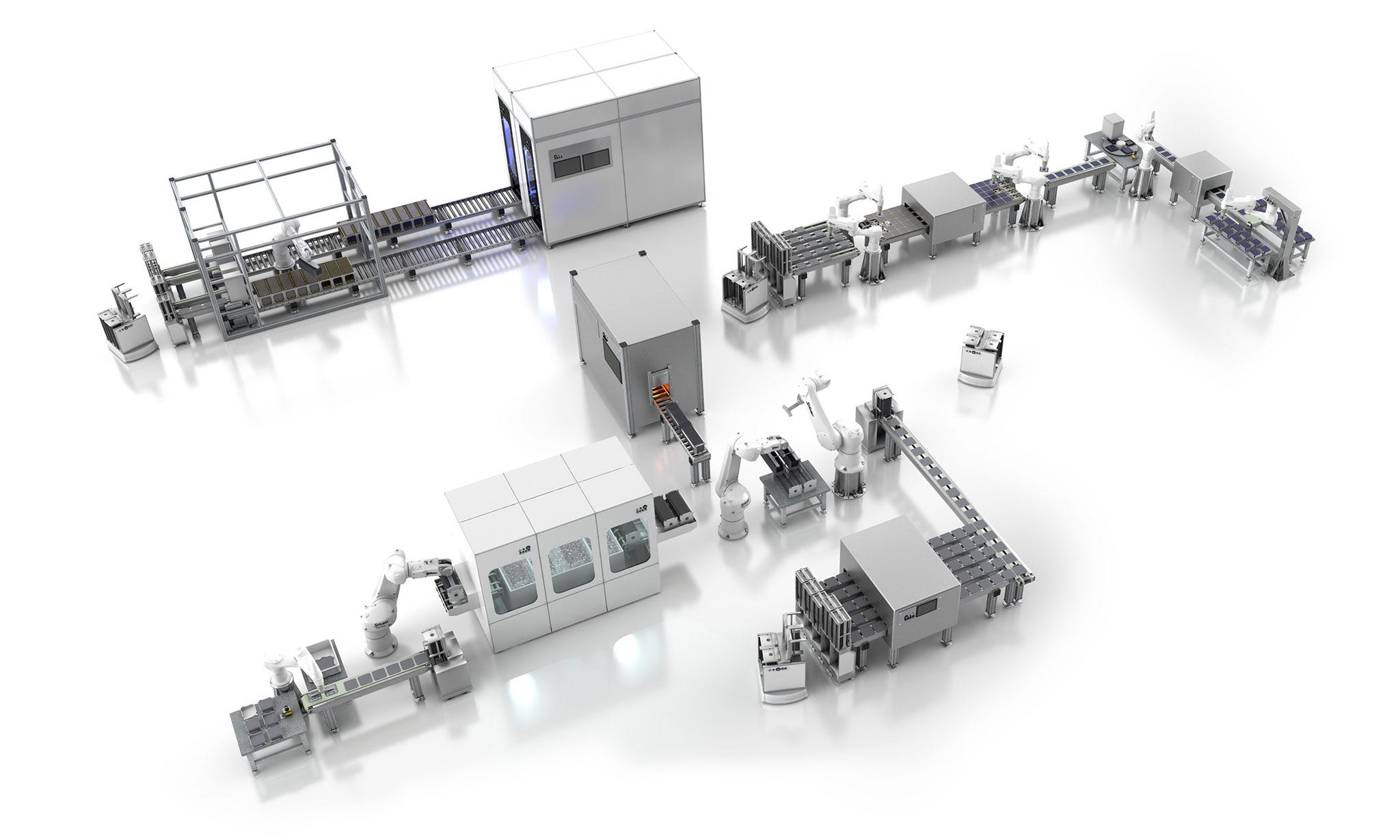

Whether for the classical BSF/P-PERC cells, or for the latest N-type/Tandem cells, Stäubli has the right robots in its portfolio for all cell’s formats (till M12/210mm cell), different handling manners (in batch or in piece) and process (from texturing, diffusion to PECVD and sorting) . The four-axis and six-axis robots of the TS2 and TX2 series are world leaders in the disciplines of dynamics, precision and reliability, not least because of their superior drive technology. At the same time, the robots handle the valuable load with extreme care, so that wafer breakage or other damage is largely excluded. The encapsulated design of the machines also ensures exemplary cleanroom suitability.

From silicon wafer to finished solar cell

Wafer quality control

The TS2 robots allow the quick loading/unloading of raw wafer on vision control system as a first step.

Texturing

The Stäubli TX2-140/160 robots transfer the cassettes with raw wafers for texturing

Diffusion

Batch of wafers are transferred from cassettes to quartz boats by TX2 robots for Boron or Phosphorus diffusion

Cell loading/unloading for batch process

The Stäubli TX2 6 axis robots is the ideal solution for handling batches of cells for PECVD and LPCVD process. They have been widely appreciated by cell manufacturers for high precision and smooth trajectory when moving fast.

Cell loading/unloading for inline process

The Stäubli TS2 robots could meet all challenges of flexible and high speed loading/unloading of all inline processes, either for the classical texturing/wet bench, or for the latest PECVD/PVD of HJT cells.

Cell sorting and packaging

Final solar cells are tested and sorted. With the high speed TS2 robots, the handling task could be proceeded with the shortest delay and lowest breakage rate.

Robotics user’s requirements

Precision

It allows a lowest breakage rate and far less downtime of the equipment.

Smooth trajectory

Cells could be handled with the best care.

Efficiency

Because a high throughput is the key of a cell manufacturer.

Long-term reliability

The robot should always have the best performance after years of usage.

Low footprint

Because you need to make use of the small space to have the large throughput.

Connectivity

Because robot is not working alone. Tracking devices, Imaging devices are all connected.