- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

404 - page not found

This page has been moved or is no longer available

Sorry, the requested page could not be found.

You may use our seach function above to find the content you were looking for. Or find the direct links to our Division pages below.

Please do not hesitate to simply contact us getting direct answers to your questions or for any assistance finding the information you need.

More information about our four Divisions

Electrical Connectors

Stäubli Electrical Connectors develops highly reliable connection solutions based on the reliable MULTILAM contact technology. In the field of photovoltaics, Stäubli is a pioneer and global market leader with its MC4 connector portfolio. Stäubli provides connections for life in industries such as renewable energies, industrial automation applications, power transmission and distribution, railway, welding automation, test and measurement, medical devices and E-mobility.

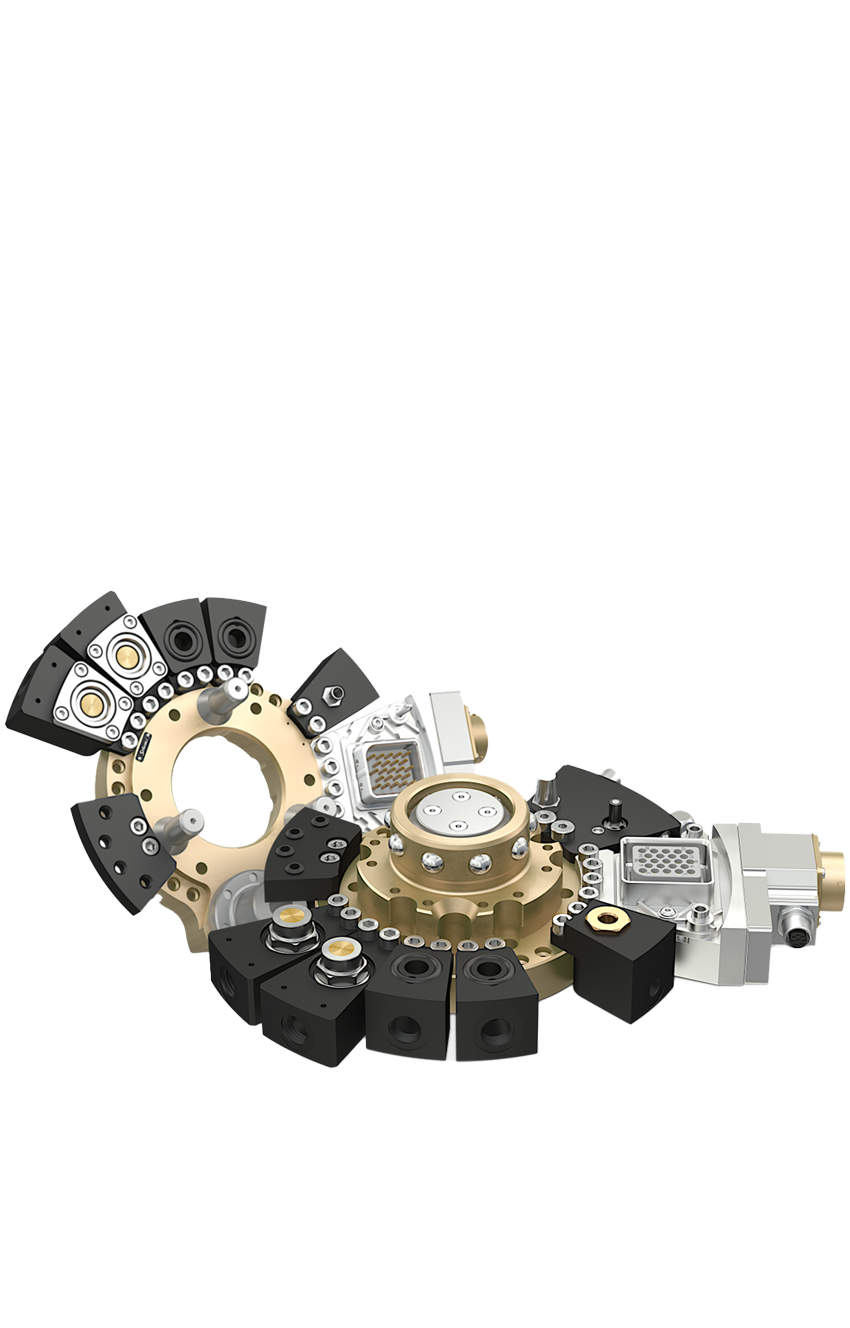

Fluid Connectors

Stäubli Fluid Connectors covers connection needs for all types of fluids, gases and electrical power. Stäubli offers standard and customized products, including quick and dry disconnect couplings, multi-connection solutions, safety break-away couplings, robotic tool changers and End-of-Arm-Tooling as well as quick mold change systems. All of them combine performance, quality, safety, dependability and durability.

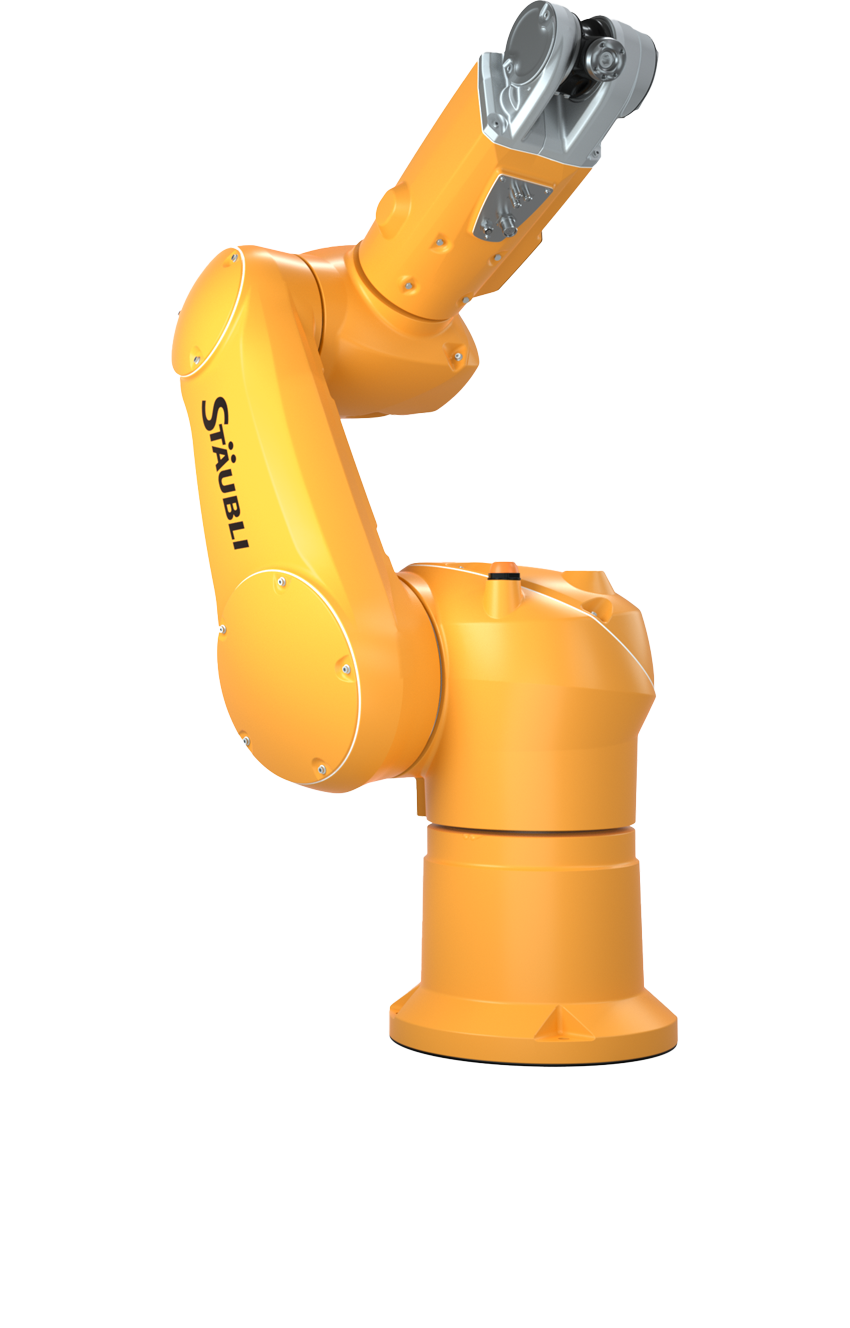

Robotics

Stäubli Robotics’ unique product portfolio contains 4 and 6 axis industrial robots, cobots, mobile robotics and Automated Guided Vehicles. The powerful, high precision solutions allow clients in many demanding industries to tackle the challenges of Industry 4.0 under specific manufacturing conditions.

Textile

As a technological pioneer in weaving industry, Stäubli Textile has been developing and producing high-quality systems since 1892. Under the roof of performance, energy savings and longevity, the comprehensive range of reliable high-performance machines for frame and Jacquard weaving as well as weaving systems for carpets and technical textiles and automation solutions for weaving preparation, allow weaving mills to optimize their production process and increase productivity.