AUTOMOTIVE INDUSTRY

Proven automation solutions for the lithium-ion battery manufacturing process

The spectacular growth for battery demand challenges gigafactories investments in their time-to-market capabilities. While production quality remains a necessary differentiator, line flexibility becomes a critical requirement to enable future product evolutions. As a result, Stäubli SCARA range is leading electrode stacking processes with major worldwide players. The whole robot range is also extensively used in downstream operations, in assembly and inspection.

Applications

Lithium-ion battery module assembly

The advanced automation knowledge from Nordfels and the deep welding expertise from Voltlabor (powered by Miba Group), delivered an amazingly efficient solution to lithium-ion battery modules assembly. The VOLTJET is a fully integrated cell, containing multiple inspection points and full traceability with the ability to process up to 100kWh battery capacity per hour. It uses Stäubli high-performing and repeatable robots for the cylindrical battery cells testing and assembly processes with a proprietary laser welding technology to form the battery module.

Lithium Battery Stacking Application

With high-speed precision and robust performance, Stäubli SCARA robots optimize cell stacking in Z-fold units—achieving ultra-short cycle times and outstanding repeatability to meet the most demanding production standards.

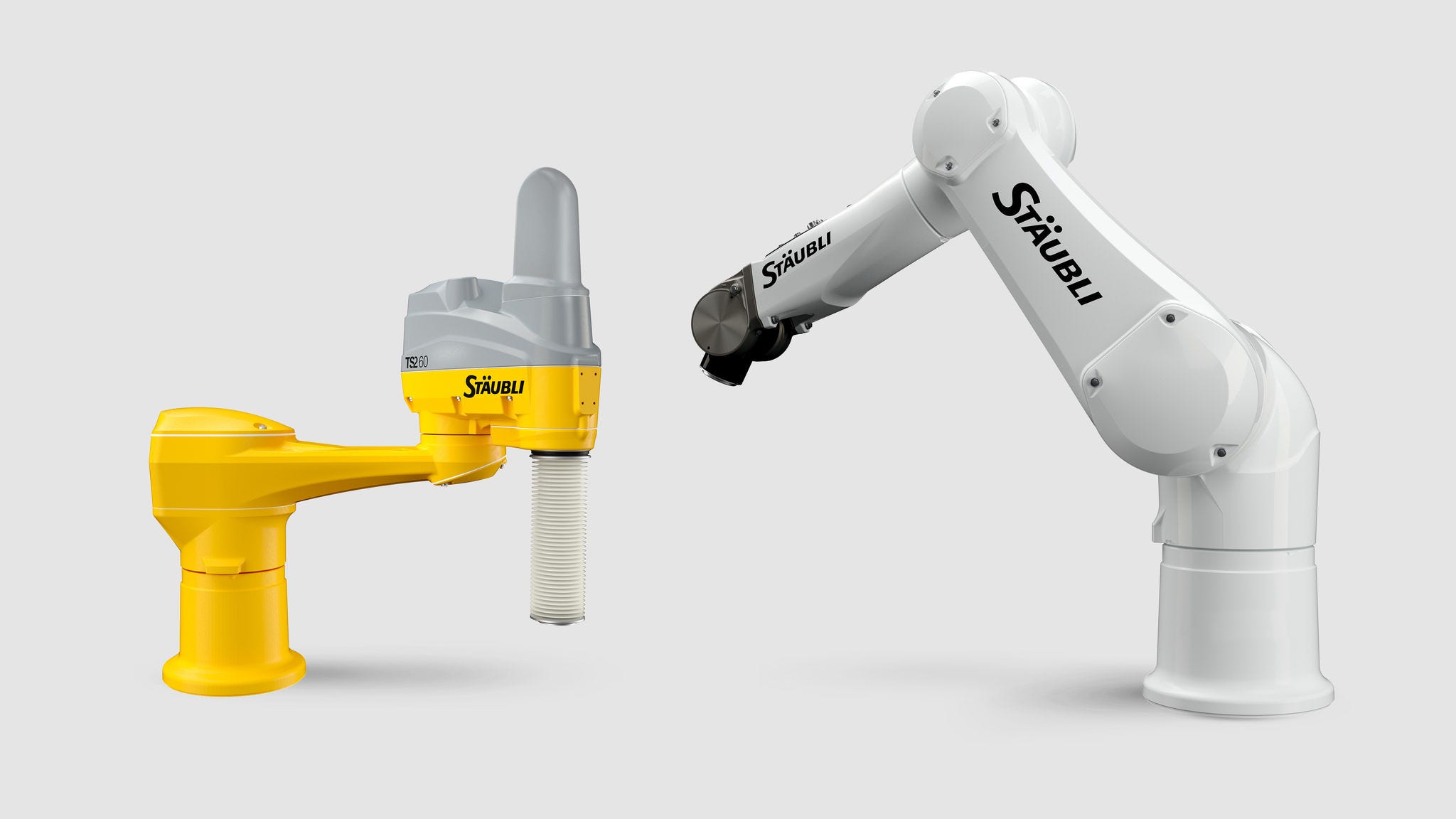

Our dedicated robot lines

-

Industrial robots

Complete line of 4 and 6 axis industrial robots designed to handle payloads of up to 170 kg. Several versions are available for sensitive environments, from cleanrooms to harsh conditions. -

ESD compliant

Our 4 and 6-axis ESD-compatible robots are designed for electronic assembly, testing and packaging operations. -

Mobile robot platform

Whatever the challenge, our modular mobile robot platforms deliver the right solution moving payload up to 450 tons with a large add-ons portfolio.