SUCCESS STORY

Fully automated cheese care system with robot

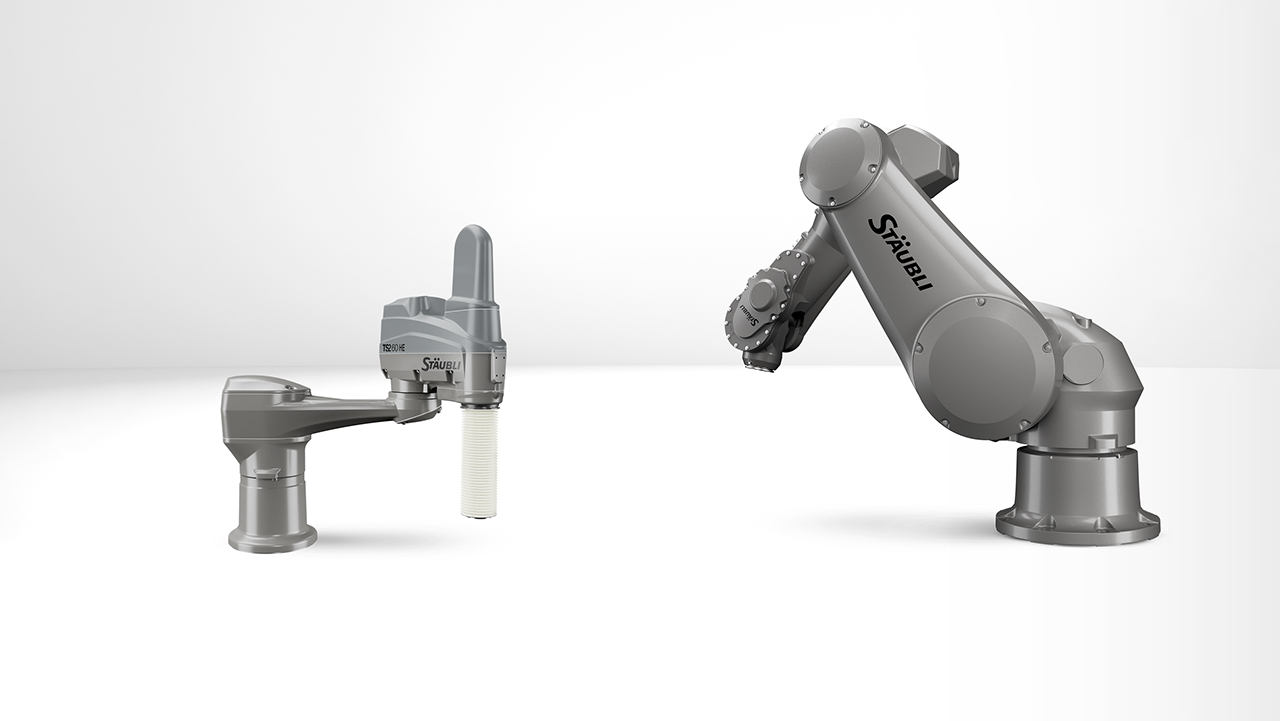

The Leupolz farm cheese dairy is setting standards with an innovative cheese care system. A powerful Stäubli six-axis TX200L HE shows its best side handling 80-kilogram cheese wheels.

CUSTOMER BENEFITS

- Employees saved from weekend work and overtime

- More cost effective and highly efficient system operation

- Meets the highest hygienic standards

- Increase in product yields

- Intensified cheese care for even better quality

TASK

Automated Care of Emmental cheese wheels

Proper care of cheese while it is ripening is critically important to the quality of the end product. This is precisely why the Leupolz Emmental cheese dairy in the Allgäu region of Germany relies on an innovative cheese care system in which a large Stäubli six-axis robot handles the 80-kilogram cheese wheels.

The Leupolz farm cheese dairy processes around 45 million liters of milk annually, equivalent to about 125,000 liters per day. One of their specialties is 80-kg round wheels, of which some 6000 units leave the dairy annually, around 10% of which are Demeter quality.

For optimum quality, the cheese wheels require care three times a week. During the average ripening time of four months, the wheels must be washed, brushed and salted 40 to 50 times, costing considerable time and money. It is no wonder that Leupolz sought an efficient and cost-effective solution for cheese care.

SOLUTION

Hygienic robots handle 80 cheese wheels per hour

Today, a robot-assisted system built by Lemmermeyer, a proven German system integrator, handles cheese care completely automatically. The system meets strict hygienic standards and offers impressive performance. Some 80 cheese wheels pass through the system in an hour. The HE (humid environment) version of the TX200L is tasked with loading and unloading the four- and eight-shelf racks where the cheese wheels are stored. These shelves are brought to the system by forklift and transported back to the ripening room when care is complete.

To handle the wheel, the six-axis robot is equipped with a special gripper, which it uses to pick up the cheese wheel positioned on a wooden board and place it on the system’s conveyor belt. In the next step, the board and cheese wheel are separated from one another. This is followed by cleaning the board and washing and brushing the cheese, which is then sprayed with salt and dried. In the final step, the cheese wheel is placed back on its board and the two travel on the conveyor belt to a defined transfer position. Here, the TX200L HE grips the board together with the cheese wheel and returns them to the correct shelving compartment.

The six-axis robot is mounted on a pedestal so it can easily approach all stations. The TX200L has a reach of nearly 2.6 meters, and with an operating weight of 100 kilograms – an 80-kg cheese wheel, 5-kg wooden board and 15-kg gripper – it reaches its maximum payload. Nevertheless, the TX200L HE runs absolutely trouble-free. The same is true of the entire system. Even the daily cleaning procedures cannot harm the system or the robot. Stäubli HE version robots are designed for rigorous cleaning procedures with aqueous media and pH between 2 and 12.

CUSTOMER USAGE

Higher quality – more satisfied employees

From an economic standpoint, use of the robot has been a winner: in the past, three people were needed to attend to the cheese. Today it is done by “half” an employee. This saves personnel costs and eliminates the need for employees to work weekends and overtime. The work environment and workload have improved significantly thanks to the higher level of automation.

Another important aspect has to do with the care of the cheese itself. The enormous capacity of the robot system enables washing intervals to be reduced significantly, which means more intense care. Thanks to the robot, the wheels can be cared for up to three times weekly. The more intensive care positively impacts cheese quality and increases product yields. And consumers can taste these benefits. Emmental from Allgäu has never been better.