- 1

- 2

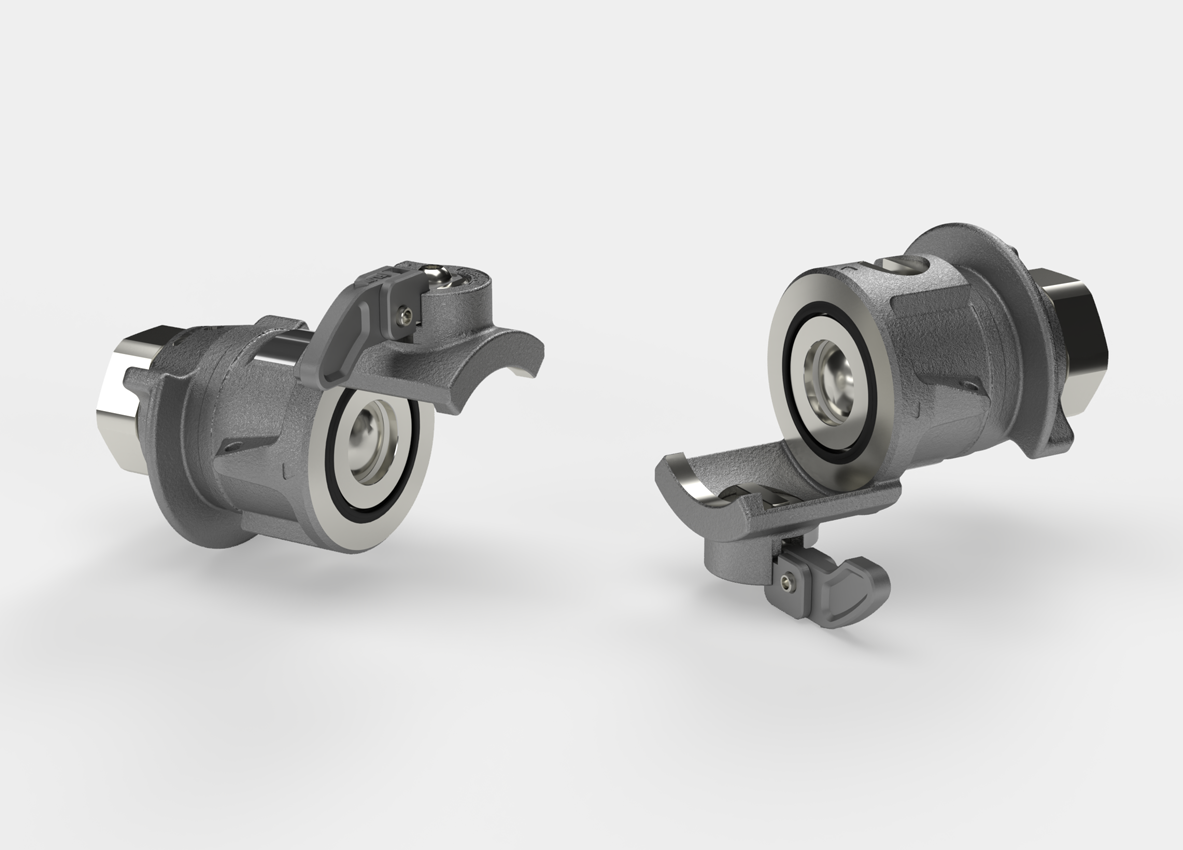

Universal Automatic Quick Disconnect UQD & UQDB for cooling data centers and supercomputers

Discover Stäubli's solution for data centers and supercomputers: the Universal Quick Disconnect (UQD), an automatic universal quick coupling designed to efficiently meet the cooling challenges intensified by AI (Artificial Intelligence).

Essential liquid cooling is now an undeniable reality for your installations. With the shift toward standardization, such as OCP (Open Compute Project) standards, and the increasing necessity for multisourcing, the UQD positions itself as the optimal reference. Benefit from Stäubli's expertise, backed by 30 years of experience in liquid cooling and 10 in electronic cooling, for seamless integration and superior cooling performance, ensuring the reliability and efficiency of your cutting-edge equipment.

Data Centers & Supercomputers: Increasingly significant needs

The rise of data centers and supercomputers is inextricably linked with contemporary technological advancements, particularly those related to Artificial Intelligence (AI). These facilities, which are essential for processing and analyzing data on a large scale, generate considerable heat that must be efficiently managed to prevent any risk of failure. Liquid cooling solutions are vital for this purpose, significantly outperforming the capabilities of traditional air cooling systems.

The market demands not only highly efficient cooling systems but also ones that are flexible and standardized to allow multisourcing. This is crucial for ensuring the continuity of operations, even in the event of a component malfunction. Compliance with OCP (Open Compute Project) standards is becoming increasingly important, enabling market players to access multisourcing options.

Approved by NVIDIA.

APPLICATIONS

- Data center

- HPC

- Internet switch

- Electronics (Liquid cooling of electronics)

- Supercomputers

- Thermal Management

- Rack Systems

- IT Cooling

Get UQD documentation

How Stäubli UQD & UQDB are answering these needs?

Superior spillage control

Designed with superior sealing control and a dripping rate that exceeds OCP specifications, Stäubli's UQD ensures unprecedented reliability.

Optimized flow Rate and Pressure Drop

The optimized design provides excellent flow with minimal pressure loss, thus enhancing the overall efficiency of the cooling system.

Intuitive visual marking

Practicality is also a major advantage of the UQD, with its visual marking in blue and red to easily identify the inlet and outlet circuits

Effortless automatic connection

The automatic connection mechanism facilitates integration into high-density spaces and ensures simplified connectivity, even within blade servers.

The Stäubli UQD & UQDB range characteristics

Characteristics UQDB blind mate

- For blind mate connection behind blades

- Superior choice for densely packed and hard-to-reach environments

- Ideal for server rack systems where accessibility is limited

- Misalignment technology, up to 0,8mm for an optimized integration

| Technical specifications | Fluids | Construction |

|

| Stainless steel |

Characteristics UQD Universal Quick disconnect

- For connection between racks and liquid cooling system via hoses

- For liquid cooling distribution inside blades

- Ideal for easy manual operations and intuitive use

- Adapted to high-density spaces

| Technical specifications | Fluids | Construction |

|

| Stainless steel |

*depending on the model and operating conditions