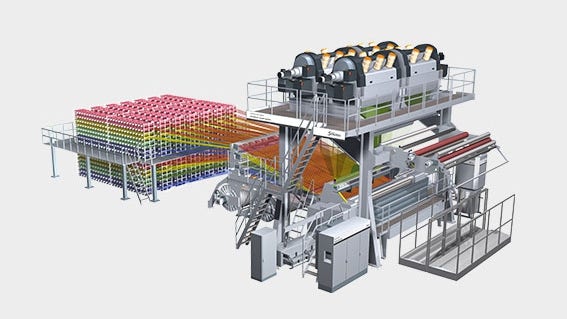

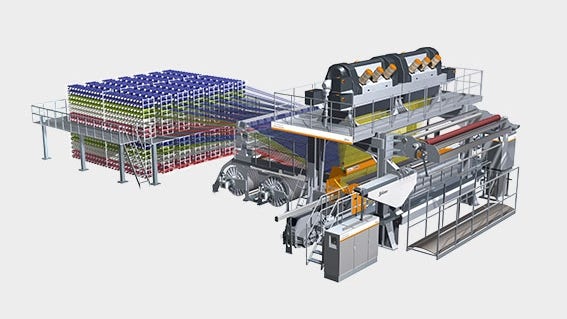

Carpet weaving machine ALPHA 580 UNIVERSAL

The ALPHA 580 UNIVERSAL carpet weaving machine has been developed for carpet manufacturers that weave a wide variety of carpet qualities, with different carpet sizes up to 5.3 m weaving width.

This weaving machine is Stäubli's answer to today's market requirements such as rapid design changes and sophisticated weave structures. Convenient yarn handling, compactness, and high operational reliability combined with long service life are decisive advantages of the ALPHA 580 UNIVERSAL carpet weaving system.

The extraordinary adaptability and productivity of the overall system will delight any carpet weaving mill searching for an efficient production solution.

Advantages

- Up to 92 colour combinations can be realized on an 8 frame machine due to the possible double and triple point technique.

- Depending on the reed density up to 16 colours are possible.

- Low, mid-range and high density carpets can be produced.

- Up to 33,792 pile threads by combining four Jacquard machines on the top.

- The system offers exceptional operational reliability.

Applications

- Cut pile

- Cut pile and flat fabrics

- Patterning on the ground

- Weft patterning

- Reverse

- Sisal

- High pile

MAIN CHARACTERISTICS

FUNCTION | ALPHA 580 UNIVERSAL |

|---|---|

Rapier principle | Double rapier system with take-over on the top, direct drive technology |

| Weft insertion | Aerostatically-guided rigid rapier ensures maximum service life of the rapier rods |

| Multi Weft Selection | Rich pattern possibilities with up to 2x6 weft channels |

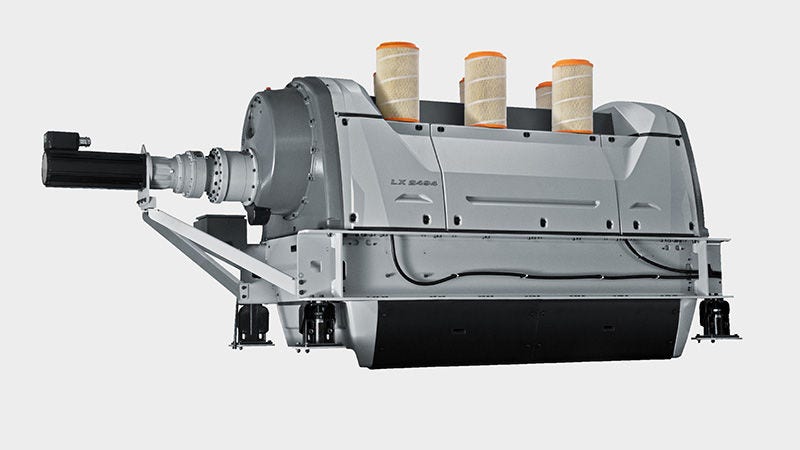

Shed formation of pile yarn | Jacquard machine LX 2494, up to 33,792 pile threads by combining 4 machines |

Shed formation of the ground warp | Electronic rotary dobby with up to 12 harness frames |

| Warp tension control | 2-tier warp beam stand supports equal warp tension; its construction allows optimum handling, operability, quick installation and shows compact design |

| Separating thread area | Ingeniously designed separating thread area offers excellent visibility of warp and pile yarns |

| Pile yarn cutting | Cutting knife actuated by toothed drive belt, with two-sided grinding units, for uniform pile heights |

| Carpet draw-off | Full-metal long-life needle rollers with high needle density, assure gentle handling, even for sensitive carpet backs |

| System Control | 1 centralized controller, permanent status display |

Stäubli Textile also offers you...

-

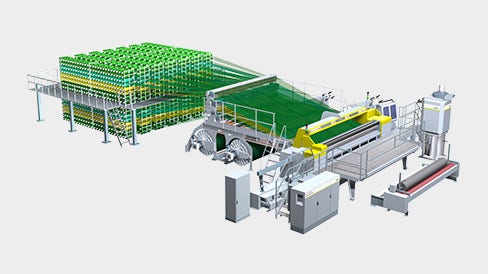

ALPHA 500 XHDC

ALPHA 500 XHDC carpet weaving machine is the ideal solution for producing high-density carpets. -

ALPHA 500 SINGLELOOP

The carpet weaving machine that is well suited for the economic production of loop and flat carpeting. -

ALPHA 500 LEANTEC

The must-have carpet weaving machine for producing specific applications such as artificial grass or shaggy. -

Carpet Qualities

Overview of binding possibilities showing ground bindings and weft effects produced on ALPHA carpet weaving machines. Weaves and fibers. -

TOPMATIC warp knotting machine

The TOPMATIC warp knotting machine supports operating versatile and finest yarn types. -

LX 2494 Jacquard machine

Electronic Jacquard machine is ideal for weaving carpet, velvet and technical fabrics on all types of weaving machines, up to 8,448 hooks, with 3-position modules.