Stäubli Tool Changer Helps TPR’s Aerospace Project Take Off

The challenge

Maximise Robot Utilisation During Drilling & Inspection Tasks

True Position Robotics (TPR) provides smart solutions for robot drilling and inspection, designed to fit within a digital landscape. As part of the Innovate UK funded ADI Project (Automated Drilling & Inspection), TPR’s technology plays a key role in transferring robot programmes which have been created offline, to the real robot, and guiding the robot in space to become a true digital twin.

As part of the project, multi-tasking robots are required prior to and following machining operations. To optimise the utilisation of the robot in this application a robot tool changing system would be required. A necessary condition however is, that any tool changer system used would be able to not only deliver the different media and services required, but crucially provide consistent availability, precision, and performance.

The solution

Stäubli Tool Changer Helps TPR’s Aerospace Project Take Off

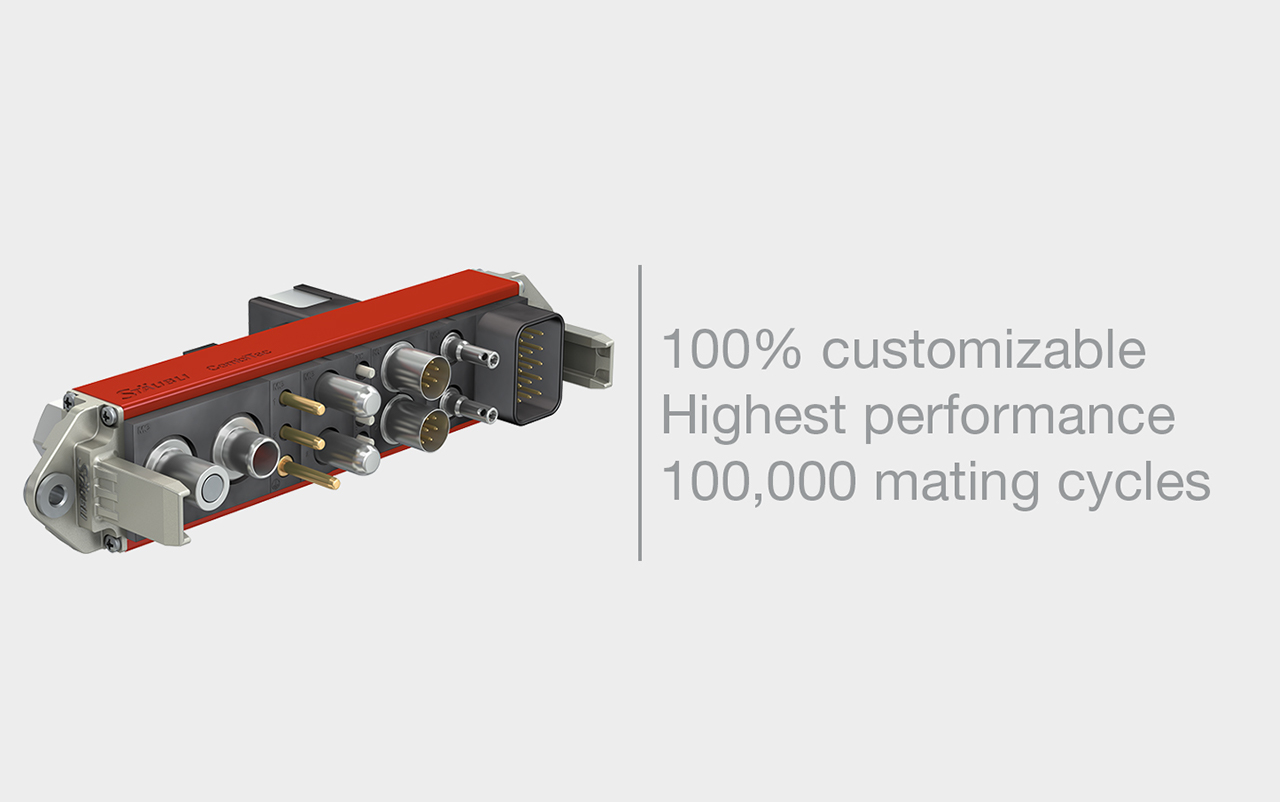

Stäubli worked closely with TPR Limited on this project to specify the MPS 130 robot tool changer to manage different applications and CombiTac connectors which connect the water, air, power, and data signals required for this aerospace project.

The ability to obtain both the connector and tool changing technologies from a single source, as opposed to using hybrid technologies from different suppliers, is seen as a benefit as the manufacturing processes, materials, tolerances and ultimately product reliability and compatibility is guaranteed.

The result

Reliable & Efficient Robot Processing

Stäubli’s MPS 130 robot tool changer and CombiTac connectors are now at the heart of this innovative system, performing the tool changing operations between the inspection systems used to define datums prior to machining, the drilling technology used to produce and countersink the holes, and finally the laser scanning system for final process verification.

THE PARTNER

True Position Robotics (TPR Limited) are technology providers and recognised as leaders in the field of smart solutions for robotic drilling and inspection, providing levels of accuracy that are ten times better than that of an off the shelf robot.

The company’s technology is helping to revolutionise manufacturing processes within the aerospace, automotive and urban transportation sectors.

“The main benefit for us is when we disconnect and then re-connect the different tools, we don’t have to worry about the consistency or quality of the different services.

We can take that for granted as we have full confidence in Stäubli’s solution.”

Roger Holden, Director