SUCCESS STORY

High-tech testing methods for aviation

The highest demands are placed on robots used in ultrasonic testing of fuselage components for modern jets. Perfect synchronization and exceptional precision are required, and Stäubli six-axis robots deliver exactly that.

CUSTOMER BENEFITS

- Precisely synchronized movements

- Accurate inspection of large composite components

- Adapted for use in humid environments

- Excellent support from Stäubli UK

TASK

Robot-assisted ultrasonic testing of composite components

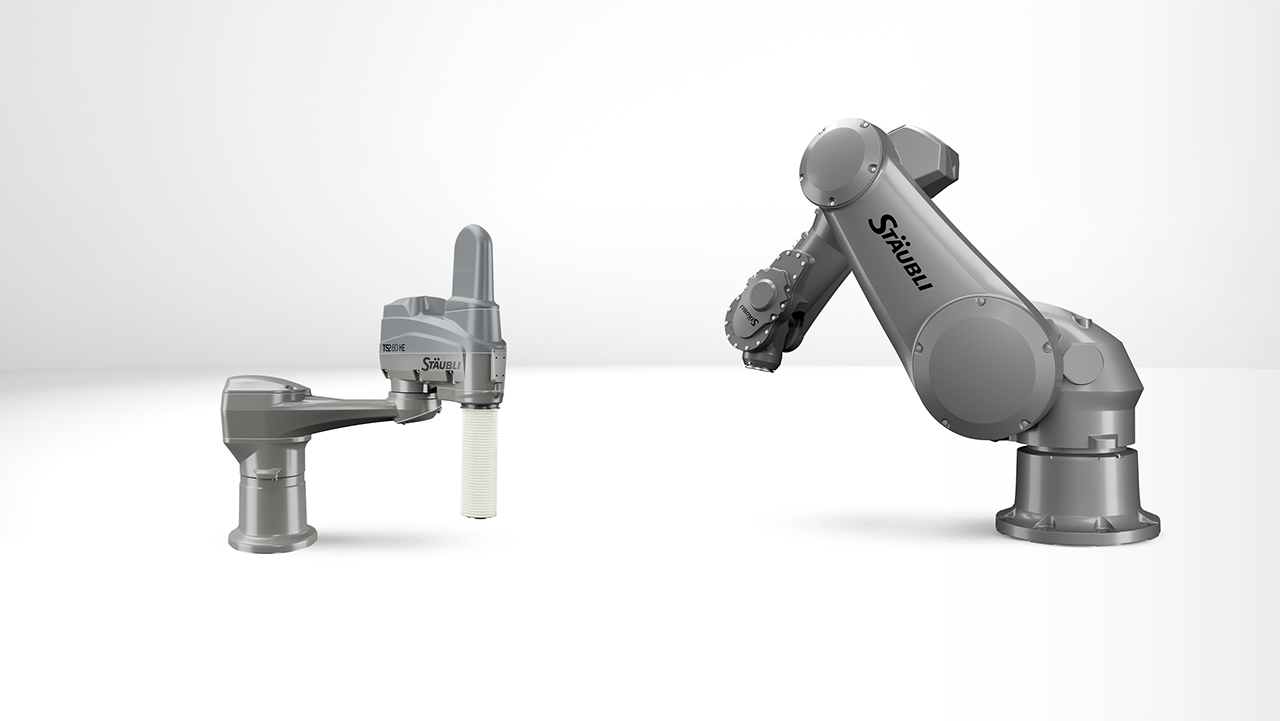

British company Ultrasonic Sciences Ltd. (USL) builds systems for ultrasonic testing of components and structures such as aircraft fuselages. During testing, two robots with a total of 18 axes must be coordinated and synchronized—with maximum precision under humid conditions. The highest demands are placed on precision, which is where Stäubli six-axis robots in the HE design excel.

When used in critical applications, fiber-reinforced composite components must be tested for defects such as delamination or gas inclusions. This is done with an ultrasonic method using water as the carrier substance. Small parts are tested in a water bath. Larger components, such as aircraft fuselage half-shells, are simultaneously exposed on both sides to synchronized moving water jets, which must contact both sides at the same time and at the same angle. This requires the control and coordination of multi-axis movements with the highest precision.

SOLUTION

Paired robots with 18 synchronized axes

In USL’s ultrasonic systems, these movements are performed by two Stäubli TX200L HE six-axis robots, each moving on a linear axis. The “L” stands for “long reach.” These robots are equipped with a longer arm with a reach of 2609 mm, enabling them to inspect large fuselage parts. The “HE” designation indicates robots designed for use in humid environments.

The two robots, synchronized via their control systems, perform their tasks with the utmost precision. Parallelism and perpendicularity meet the strict requirements of the application. The Stäubli robot controllers interface with USL’s “master” multi-axis controller, an Omron CK3E PMAC, which controls up to 32 axes simultaneously: six robot axes per side, a seventh linear axis, and an eighth for the dynamic motorized end effectors. With the pump control system, this totals 18 controlled axes per testing system. Despite the complexity of this process, users can configure testing for new component types themselves using USL’s scanner software.

- Teaser

- Teaser

CUSTOMER USAGE

Impressive precision

Testing such a system without components demonstrates how precisely the robots, along with the linear axis and peripherals, operate. The two Stäubli robots then perform complex, perfectly synchronized or opposing movements, not only on all their own axes, but also on the seventh linear axis. They move in such a way that the two water jets from their tools meet exactly in the middle, forming a fountain in the shape of an umbrella, centered precisely between the water jets and vertically aligned. This makes an impressive visual display of their precision. And manufacturers of composite components can be sure that even the slightest irregularity will be detected.