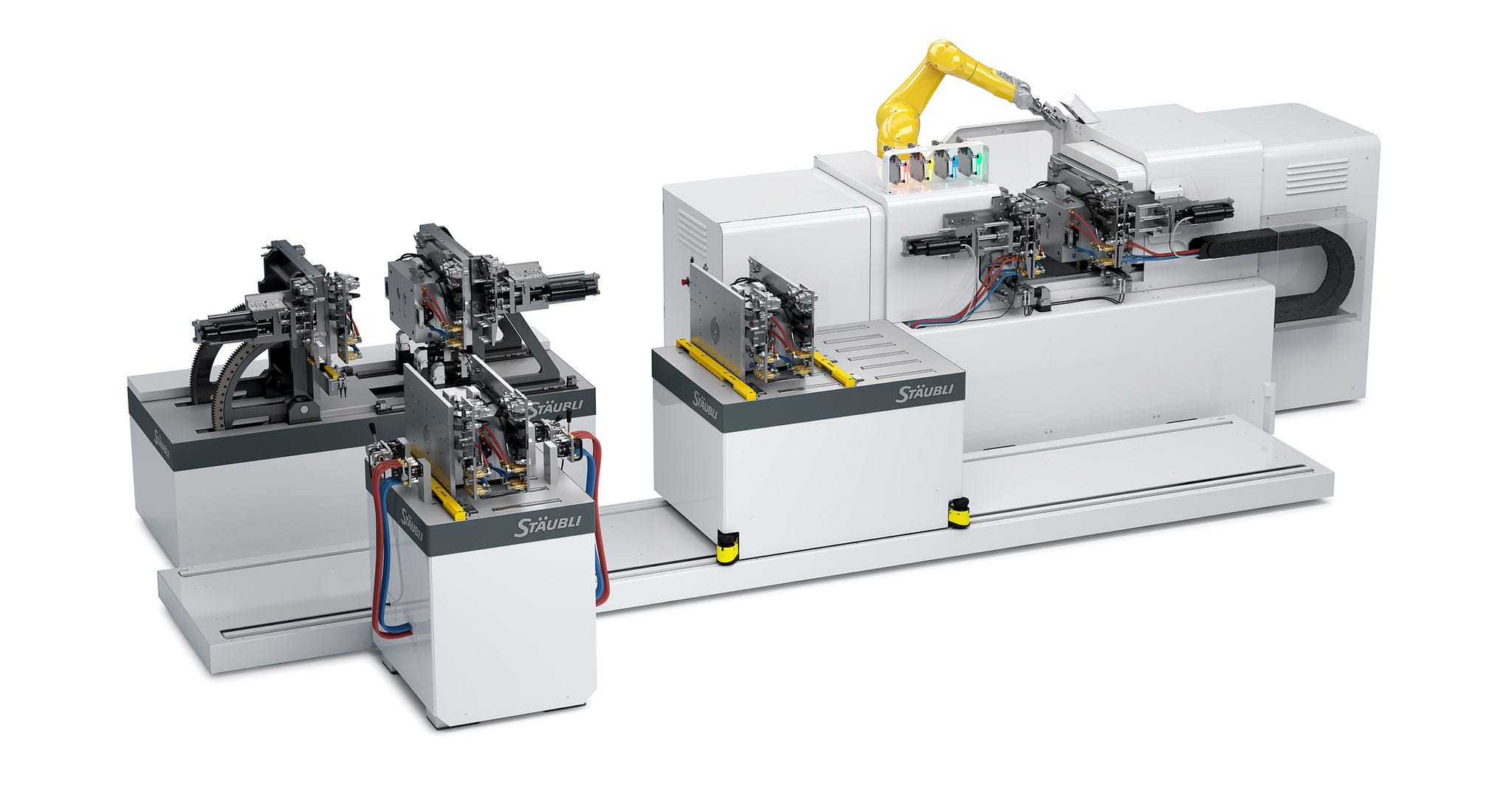

Le changement de moule en 1 minute grâce à des solutions globales et automatisées

Les solutions QMC (Quick Mold Change) de Stäubli, axées sur l’automatisation des processus, la performance et l’innovation, sont essentielles pour le processus SMED (Single-Minute Exchange of Dies). Grâce à son expertise dans le chargement et le bridage de moules, la connexion d’énergie et les solutions robotisées, Stäubli propose des solutions ciblées ou globales pour optimiser la productivité et la qualité dans l’industrie plastique.

Inspection des moisissures

Les postes de travail Stäubli facilitent et sécurisent le travail sur des moules de très grande taille.

Manutention des pièces

Avec la demande croissante de changements de moules multiples, la flexibilité est essentielle pour rester compétitif. Pour les processus industriels robotisés, les solutions modulaires permettent au robot de changer d’outil de manière entièrement automatisée et en temps opportun.

Transfert et chargement du moule

Postes de travail fixes et navettes : des solutions personnalisées en fonction des spécifications des outils, des machines et des processus de production.

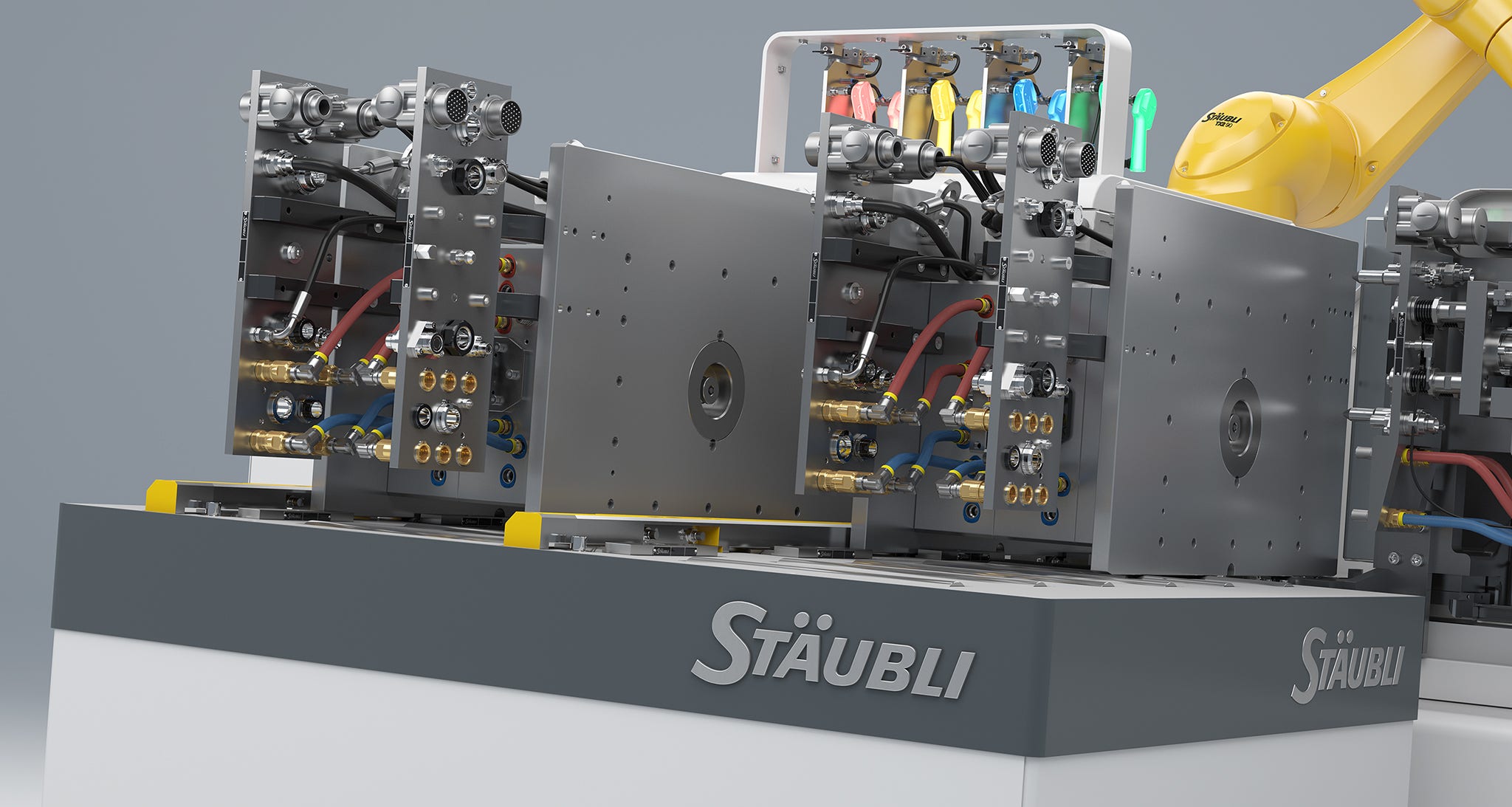

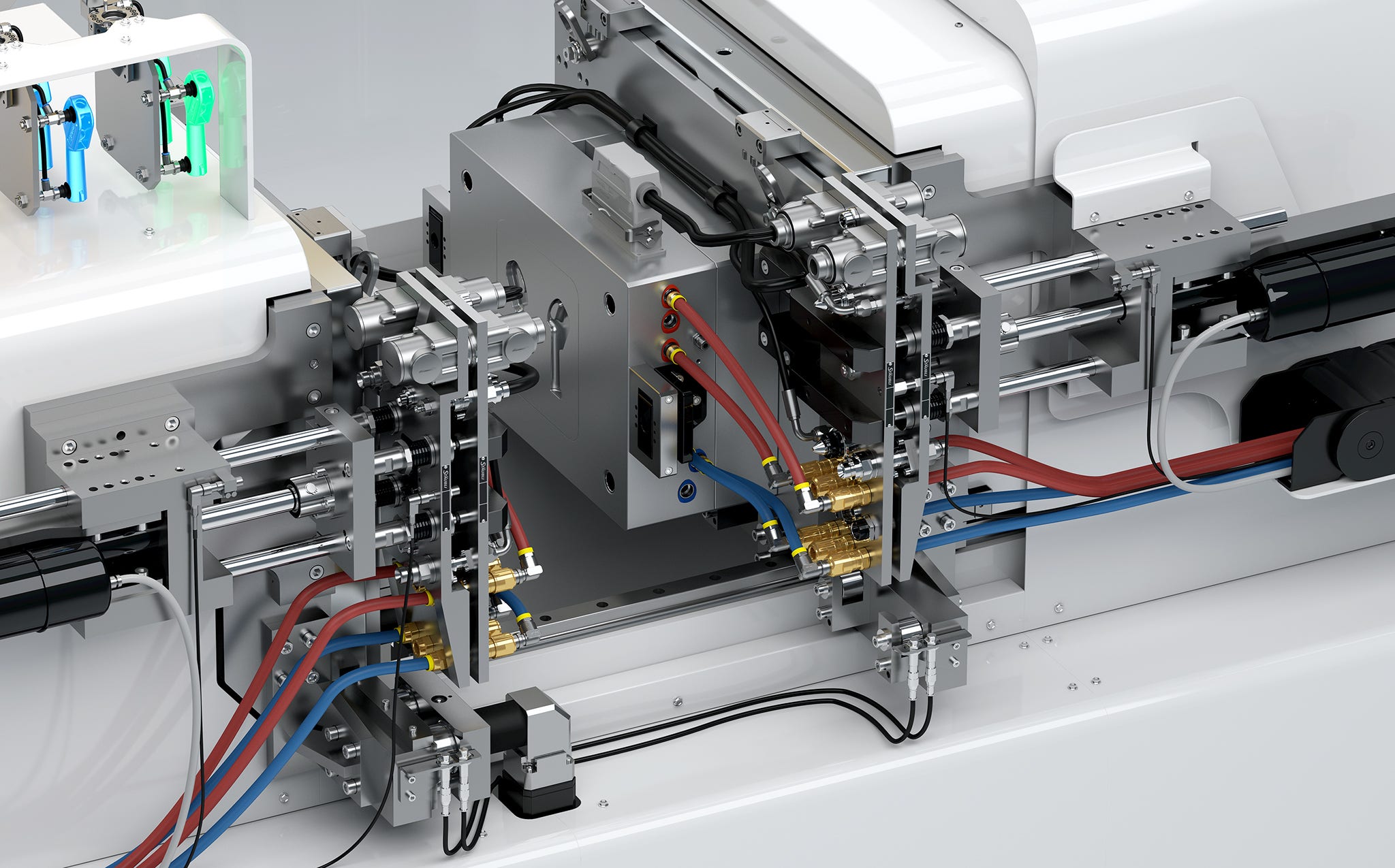

Raccordement des circuits d’énergie

Accouplements rapides et connexions centralisées pour la gestion thermique des moules, des applications hydrauliques et des circuits électriques.

Serrage du moule

Mécanique, hydraulique ou magnétique : trois technologies de serrage Staubli disponibles qui vous garantissent la solution appropriée.

Préchauffage du moule

Les stations de préchauffage permettent au moule suivant d’atteindre la température de fonctionnement pendant que le moule actuel est encore en utilisation. Cela réduit au minimum les temps d’arrêt entre les changements de moules.

Applications dans la plasturgie

Grâce à l'étendue de son offre et à son expertise, Stäubli propose des solutions sur mesure ou globales dans le domaine de la plasturgie. Chaque étape cruciale du processus de changement de moule est optimisée pour garantir sécurité, rapidité et efficacité. Que ce soit le transfert, le bridage et la thermorégulation des moules, l'inspection ou l'automatisation via des changeurs d'outils pour robots et des connexions centralisées, chacune de ces applications vise à aider les industriels à maximiser leur productivité tout en maintenant une qualité irréprochable.

- Connexion des circuits d'énergies

- Bridage des moules

- Transferts et chargements des moules

- Inspection des moules

- Robots et changeurs d’outils

Optimiser chaque étape de la chaîne de production

Stäubli accompagne les fabricants à chaque étape de leur parcours de transformation, en réduisant les temps de changement de moules avec la méthodologie SMED et en automatisant la production avec des solutions performantes. Découvrez comment notre expertise globale, de la connexion des énergies à la robotique, aide à construire des environnements de production plus intelligents, plus agiles et plus compétitifs.

Découvrez notre gamme complète de solutions dans l’industrie plasturgie

Identifiez rapidement les solutions Stäubli les plus adaptées à vos besoins grâce à notre outil de recherche de produits intuitif. Que vous soyez à la recherche de systèmes de bridage de moules, de solutions de connexion rapide ou de changeurs d’outils pour robots, cet outil vous aide à naviguer dans notre gamme complète et à trouver les produits adaptés aux exigences spécifiques de votre application.

Pourquoi choisir Stäubli ?

Pour répondre aux exigences en constante évolution de l’industrie, vous avez besoin d'innover, bien sûr, mais vous avez également besoin de solutions éprouvées et efficaces. En tant que leader mondial des technologies de connexion, Stäubli vous aide à réduire les temps d’arrêt, à améliorer la sécurité et à adopter l’industrie 4.0. Visionnez nos trois courtes vidéos pour comprendre comment nos experts relèvent les principaux défis du bridage magnétique et des connexions centralisées.

Découvrez comment nous aidons nos clients

Success stories de nos clients

Stäubli va au-delà des attentes de ses clients du secteur de la plasturgie en proposant des solutions innovantes et fiables qui améliorent la productivité et l’efficacité. Nos clients nous font confiance pour notre expertise inégalée et notre engagement envers la qualité, assurant leur succès et leur satisfaction à long terme. Découvrez nos success stories !

Prenez contact avec notre spécialiste !

Contactez notre spécialiste pour obtenir des informations détaillées sur les systèmes de connexion rapide dans le processus de fabrication du plastique.

Obtenir des documentations

Inscrivez-vous pour recevoir du contenu exclusif !

Gardez une longueur d’avance, inscrivez-vous pour recevoir les dernières innovations et informations Stäubli !