- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

SUCCESS STORY

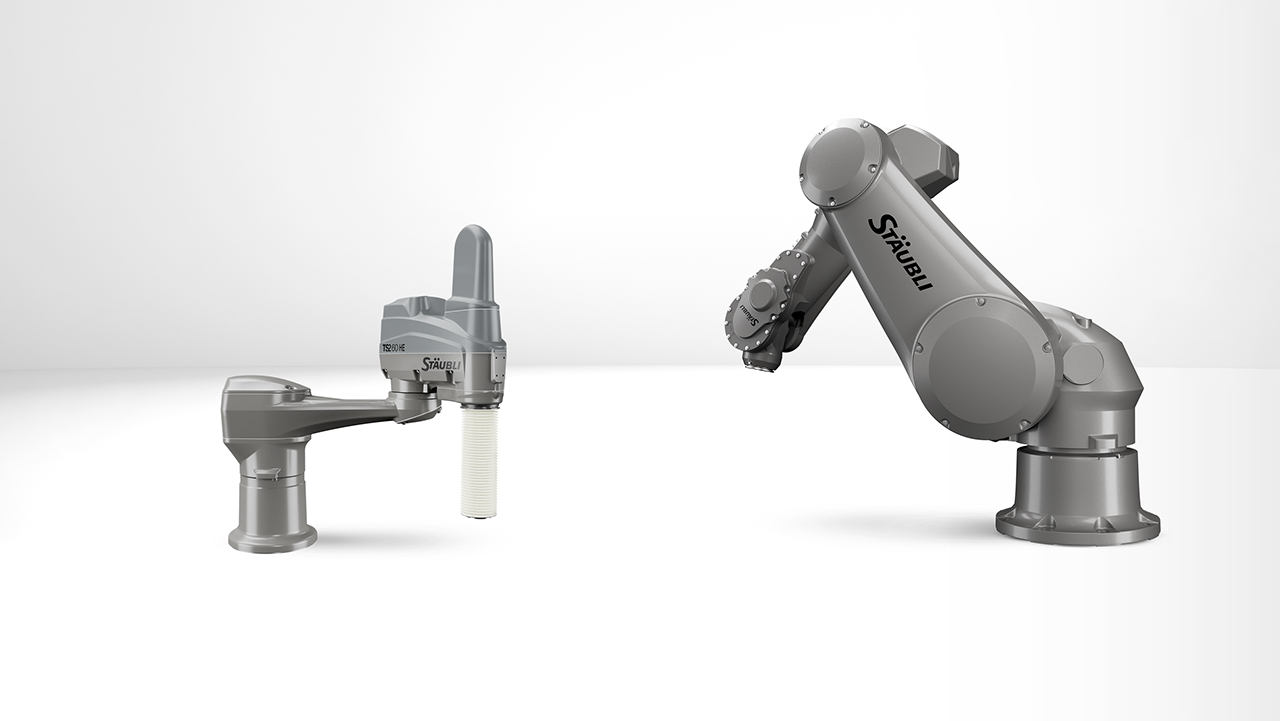

HE robots excel where others fail

The management at the Nissan Dongfeng engine plant in China found out the hard way that standard robots are not at all suitable for inline parts cleaning. It was only when they made the switch to the six-axis TX200 HE from Stäubli that they found an efficient and reliable solution.

CUSTOMER BENEFITS

- Efficient and reliable cleaning processes

- Maximum availability under adverse conditions

- Compliance with clearly defined residual contamination criteria

- Short cycle times thanks to inline cleaning

TASK

Six-axis machines for inline parts cleaning

100 percent humidity and a pH of 9: in such conditions, the deployment of robots poses real challenges. These are the very parameters under which Stäubli robots are delivering reliable service on the parts cleaning line at the Nissan Dongfeng engine plant in China. Component cleanliness plays an extremely important role in modern engines. Even the most minimal contamination can lead to damage with severe consequences, which is why parts cleaning is considered so crucial. In the automotive industry, clearly defined residual contamination criteria apply, which can only be permanently adhered to when reliable processes are in place.

On this basis, an efficient and highly automated parts cleaning line was installed at the plant in Huadu. When it first went into operation, though, the six-axis robots installed were not supplied by Stäubli but rather by another manufacturer. However, these were not able to cope with the tough conditions. Frequent breakdowns and high maintenance costs eventually persuaded the management to completely replace the robots with high-performance Stäubli TX200 HE six-axis machines.

SOLUTION

An indefatigable robot for harsh environmental conditions

The cylinder blocks and heads are manufactured on four lines. At the end of each line, there is a cleaning station, with one cell for the precleaning and one for the final cleaning. The cycle time per station must not exceed 65 seconds.

The TX200 HE hoists the cylinder block weighing up to 30 kilos (the cylinder heads weigh up to 18 kilos) with a gripper from a roller conveyor, swings it across to a bath and lowers it until it is submerged. To ensure that the nooks and crannies are reliably flushed, the six-axis robot follows a meticulously programmed motion profile.

The robot arm is immersed no further than its wrist, yet even so, the housing is permanently wet from being splashed with cleaning fluid; this is because the cleaning medium itself is also agitated, which is the only way to ensure optimal cleaning results. Subsequently, the thoroughly cleansed part is passed through a drying unit.

CUSTOMER USAGE

Positive outcome in an unfavorable environment

The Nissan Dongfeng management are highly satisfied with the performance of the Stäubli robots on the inline parts cleaning lines. These large six-axis machines have operated reliably for a number of years now, despite the extremely adverse environmental conditions. Wang Meng, Divisional Head of Technology: “The robots are very precise and reliable.”

The Stäubli TX200 HE was developed for such applications and has a package of specifications that includes resistant surface treatment and special seals at the joints. The wrist is IP67 rated and even able to withstand immersion in liquid media. Furthermore, all connections are located under the robot pedestal where they are well protected from

moisture.

News of the positive outcome has meanwhile spread to other sites: 16 Stäubli HE robots are now used in parts cleaning at the Zhengzhou plant, where Dongfeng manufactures vehicles under its own brand name.