- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

AUTOMOTIVE INDUSTRY

Process quality enhanced for passive and active safety components

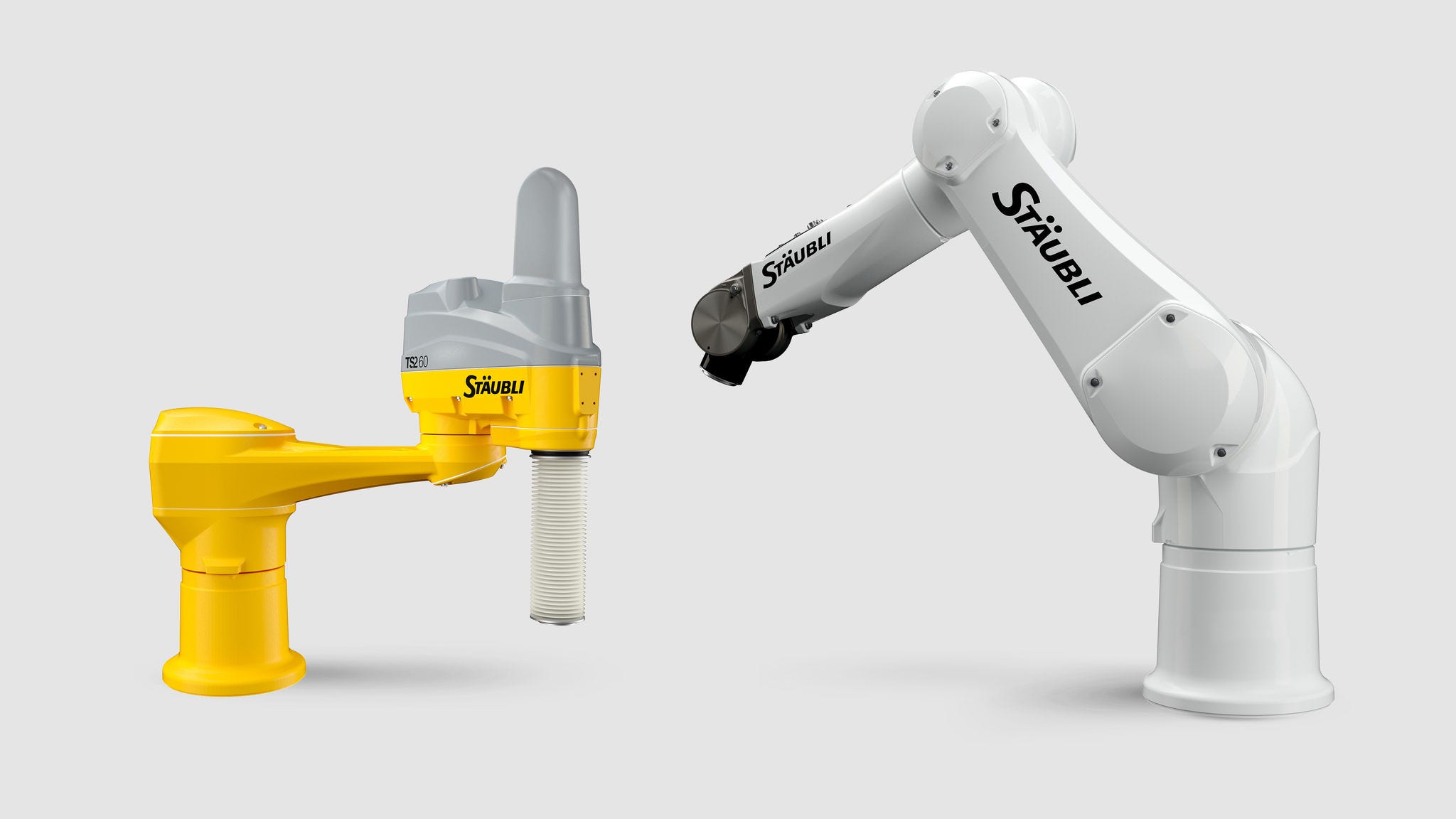

Led by the premium segment, the volume and capabilities of safety devices in a vehicle never ceased to increase. With production quality as a major requirement, the drive towards robotics seems obvious. Stäubli benefits from a long-lasting expertise in major applications such as assembly and inspection but also enabled demanding applications that were considered challenging to automate.

Success stories

-

Production of ABS systems

Automotive manufacturers are demanding greater precision from anti-lock braking systems. These exacting specifications can no longer be met with manual assembly lines. Robot-based automation solutions opened up new dimensions in terms of quality. -

Coating headlamp lenses

Currently, all plastic headlamp lenses come with a protective coating. Thanks to the latest generation of robots, transparent micrometer-thin protective layers can be accurately applied under cleanroom conditions. -

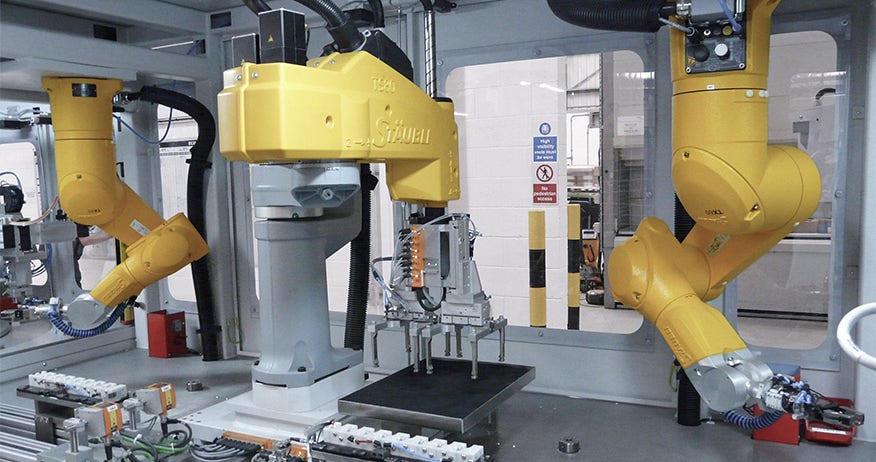

Production of airbag control sensors

Until recently, the production of airbag modules at ZF TRW in County Durham, England, relied largely on manual labor. Today, the assembly line is fully automated and the work is done by Stäubli industrial robots.