- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

Fluid Connectors

Advanced connection solutions for every industry

As one of the leading manufacturers of quick connector systems, Stäubli covers connection needs for all types of fluids, gases and electrical power. Our standard and customized products, including quick and dry disconnect couplings, multiconnection solutions, safety break-away couplings, tool changers and quick mold change systems, combine performance, quality, safety, dependability and durability.

-

Industries

Each sector has its own challenges. Find out more about specific solutions for a broad range of industries. -

Success Stories

Read how our solutions have benefited customers around the world. -

White papers

New industrial challenges, economic and social issues arise all the time. Take advantage of our expertise in different industries by downloading our white papers. -

Downloads

Access to the 3D CAD library and brochure pdf-download section.

Our solutions

-

Quick and dry disconnect couplings

Pneumatics, hydraulics, fluid logistics, cooling, breathing air, alternative fuel and other applications. -

Safety breakaway couplings

Safety components for industrial and marine applications. -

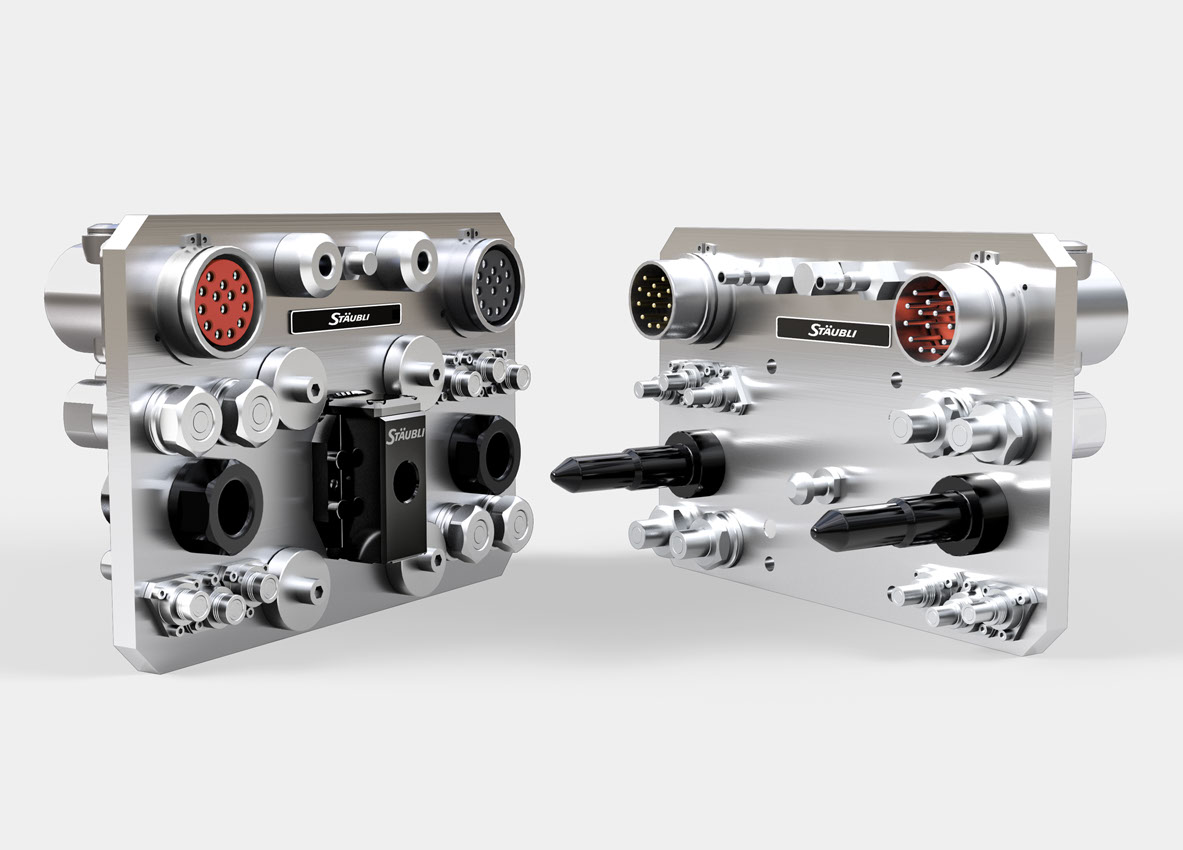

Multi-couplings / multi-pole connectors

All-in-one solutions for simultaneous fluid and electrical connections. -

Robotic tool changers & EOAT

Stäubli solutions for tool changer and end-of-arm tooling unlock the full productivity potential. -

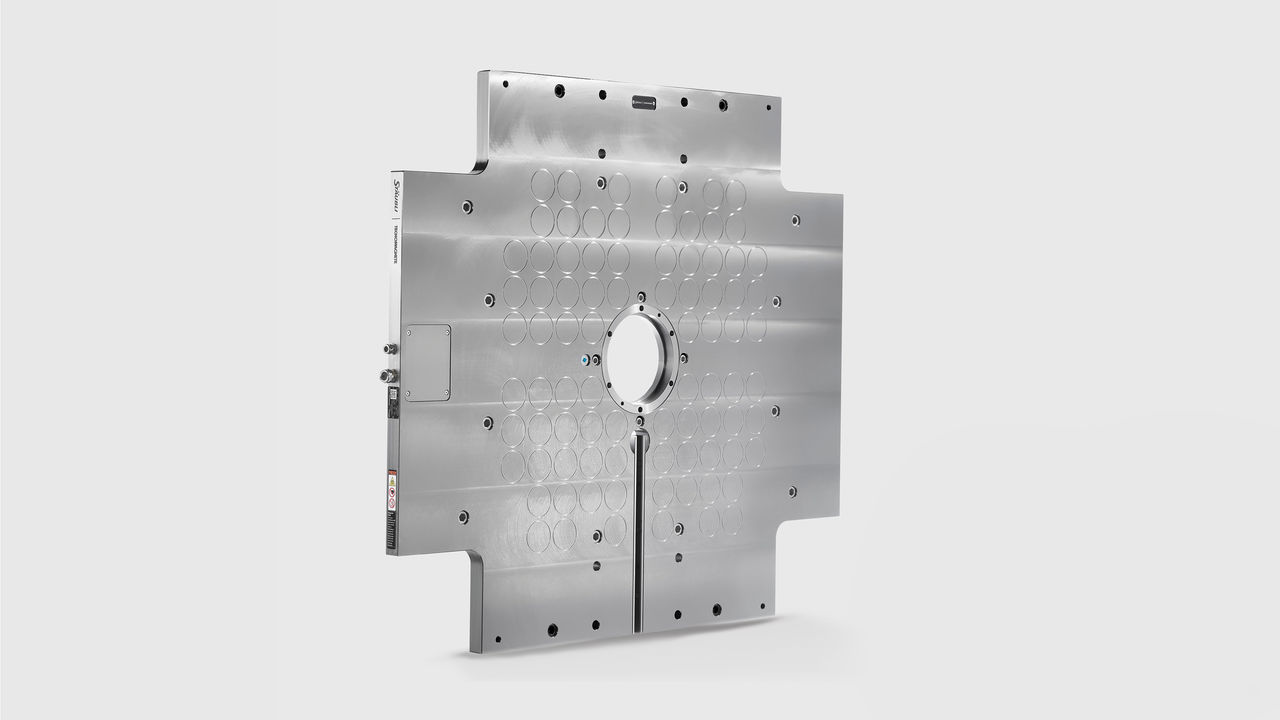

Mold clamping systems

Targeted or global solutions for safe and efficient mold clamping, transfer and maintenance in the plastics industry. -

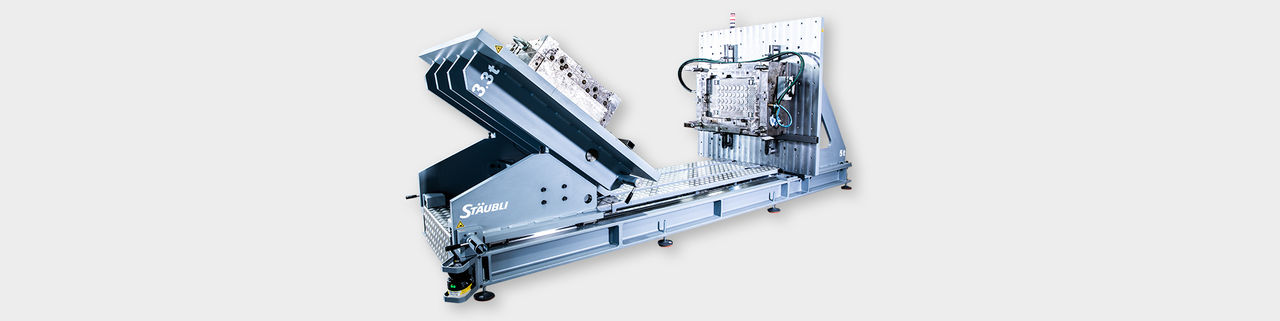

Mold loading tables

For optimizing setup times. -

Mold maintenance stations

Ensure efficient maintenance while adhering to the highest quality and safety standards.

NEWS