- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

The Stäubli UNI-LINK system

Our UNI-LINK system for process optimization between warp beam stock and weaving machine assures quick style changes, short down times for the weaving machines, and a rational sequence in production. The system components can be used together with all Stäubli drawing-in installations, for all types of weaving machines and “Quick Style Change” systems, and all transport equipment.

Stäubli also offers you...

-

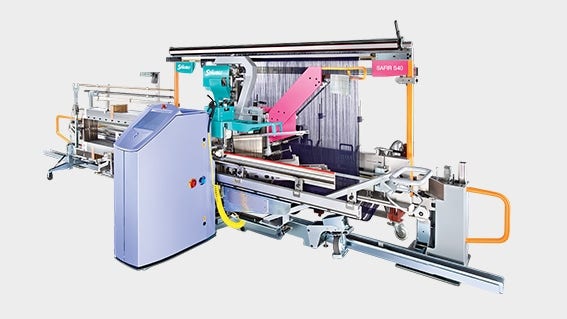

SAFIR S40 drawing-in machine

The SAFIR S40 automatic drawing-in machine is the ideal solution for mills producing a variety of standard applications. -

TIEPRO warp tying machine

The TIEPRO warp tying machine is dedicated to operating standard yarn types. -

Cam motions series S1600 and S1700

Positive cam motions for weaving basic weaves from plain weaves to heavy fabrics in rapier and air-jet weaving machines. -

Rotary dobby series S3000

High-speed electronically controlled rotary dobbies for all types of patterned fabrics in water-jet, air-jet or rapier weaving machines depends on the application.