- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

SUCCESS STORY

Robot automates sandwich production

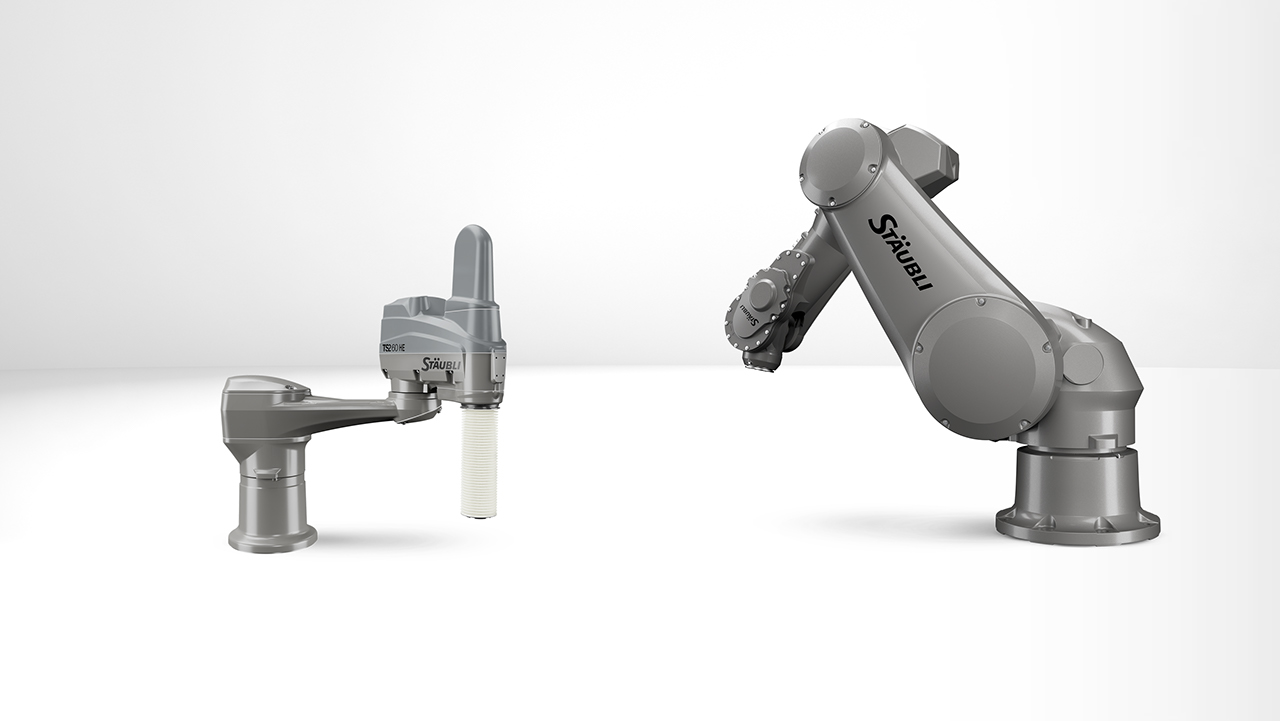

An American manufacturer of equipment for food production has succeeded in developing a fully automated line for sandwich production. At the heart of the system is a Stäubli TX2-60 HE six-axis robot.

CUSTOMER BENEFITS

- Fully automated production of different sandwich variants

- Reliable, hygiene-compliant design

- Highly dynamic robot to HE specification (Humid Environment)

- Maximum flexibility

TASK

Automated production of sandwiches

U.S.-based Grote Company Inc. specializes in automating production lines that slice, fill and cut sandwiches. Until recently, the upper and lower halves of the sandwich were put together manually. Now Grote has managed to automate this process using a Stäubli TX2-60 HE six-axis robot with wash-down capability.

Filling a sandwich is not a particularly arduous task. That is, unless it is being done on an industrial scale with a throughput of thousands of sandwiches per hour. The raw materials – slices of sausage, cheese, tomatoes and lettuce – can be difficult to handle and process. Furthermore, stringent hygiene measures have to be put in place.

Headquartered in Columbus, Ohio, Grote sees itself as a technology leader in this area of food processing. Its design team has recently launched a ground-breaking innovation on the market, the Robotic Sandwich Assembly Line, an automated system for sandwich production.

SOLUTION

Sandwich production at a rate of one per second

At the heart of the assembly line is a six-axis robot, the Stäubli TX2-60 HE. A conveyor belt delivers the sandwiches to it as two halves – the bottom slice, already buttered and filled, and the top slice, which is only buttered. The robot picks up the top slice and places it on the filling on the bottom slice. The sandwich is now whole. Next, the robot rotates the sandwich 45 degrees so that it is positioned diagonally on the conveyor belt. It then proceeds to the last station, where the sandwich is pressed and cut longitudinally to form the two customary triangular halves. Up to 60 sandwiches per minute on each of the two lines can be produced in this way. An operation that was previously performed manually is now automated.

The entire production line complies with the principles of hygienic design. All edges are rounded, so there are no dead spaces where debris can build up, and the sandwich production line can withstand even the harshest cleaning procedures. To ensure maximum availability, Grote opted firmly for a Stäubli HE (Humid Environment) robot. As an added bonus, the TX2-60 HE complies with protection class IP67.

CUSTOMER USAGE

Fully automated, highly dynamic production

Bob Grote, CEO of Grote Company, explains why this innovative system is equipped with a Stäubli robot: “In addition to the hygienic design, the high speed on the sixth axis also spoke in favor of the TX2-60 HE. The target was 60 sandwiches per minute. The robot reaches its limits here because it has to perform several motion sequences.”

The Robotic Sandwich Assembly Line can be integrated into existing production systems or operated as a stand-alone cell. In either case, the user benefits from a high degree of automation combined with high flexibility. The robot can take on additional tasks and produce different types of sandwiches without any changes to the hardware.

Using a variety of pneumatic and mechanical grippers, the system achieves an impressive level of flexibility and is capable of handling both rectangular and round sandwiches as well as wraps. Bob Grote: “We are convinced that robotics will play a major role in automated food production in the future. We see ourselves as pioneers in this regard, and we intend to apply this principle in other areas, for example in the topping and handling of frozen pizzas.”