- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

SUCCESS STORY

The modern way of testing printed circuit boards (PCBs)

Control units for automotive safety systems must function perfectly under all conditions. For this reason, one-hundred percent testing of the circuit boards used is mandatory. Thanks to robotics, this is now faster and more flexible than ever.

CUSTOMER BENEFITS

- Exceptional level of flexibility

- High output

- Simultaneous testing of different types of PCB

- Reliable protection from electrostatic discharge

TASK

Robot-assisted testing of printed circuit boards

Human lives depend on the reliable functioning of electronic assistance systems.This has led one renowned automotive supplier to install a state-of-the-art, ultra-flexible inspection system for the 100% testing of PCBs destined for use in sensitive electronics applications. The system is even able to perform high-temperature tests at 140°C.

Electronic components and systems in motor vehicles are exposed to extreme temperatures. In order to ensure the proper functioning of components, these environmental conditions must be replicated in various test procedures. Early on, Amberg-based automation specialist Baumann GmbH focused on the design and construction of test systems for this purpose.

Baumann generally prefers to rely on the highly modular standard cells it develops in house. This was the case when the supplier received an enquiry from a multinational Tier 1 manufacturer about a fully automated line for circuit board testing at room temperature and above. Baumann’s engineers came up with an individualized standard solution.

SOLUTION

Impressive plant technology with many sophisticated features

They chose the te|box, a flexible standardized platform for PCB test applications on either side of room temperature, i.e. from a low of -40°C to a high of +140°C. Thanks to exceptionally flexible features and design, this multipurpose system is able to test PCBs of widely varying types. In this specific case, 100% room temperature and high temperature tests must be conducted under rigorous cycle time criteria.

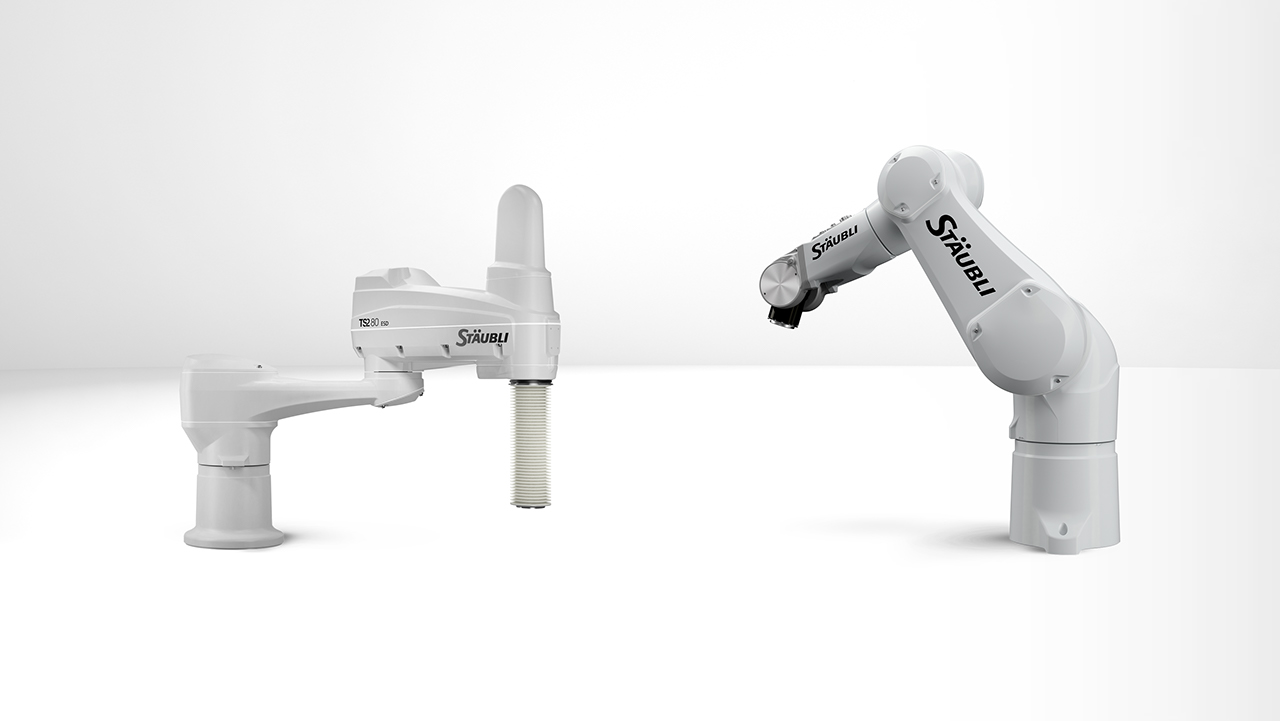

Just how flexible the setup is in practice is impressively demonstrated by the customer-specific test line. The complete system consists of two fully automated test cells on either side of an oven, each equipped with the ESD (electrostatic discharge) version of the Stäubli TX90L six-axis robot. In the first cell, the PCBs are tested at room temperature. The high-temperature tests (140°C) take place in the second cell.

This system’s sophisticated features are what make it so powerful. These include the ability to:

- Retool without any interruption to cycle times

- Perform high-temperature tests with minimal energy consumption

- Vary the number of test stations

- Reliably eliminate electrostatic discharge

- Test two different types of PCB at the same time.

CUSTOMER USAGE

Flexibility guaranteed with Stäubli ESD robots

The deployment of six-axis robots in the te|box just under a decade ago marked the start of a new era in electronics testing. It spelled the end for rigidly linked process steps and the dawn of flexibility. Protection from electrostatic discharge played as crucial a role then, as it does now, and without Stäubli ESD robots, the development of such highly flexible standard test equipment would not have been possible.

Today, all Stäubli robot series are available as ESD (electrostatic discharge) versions. In these machines all arm segments are grounded from tool to the pedestal. In addition, the robots are given a special ESD-compatible coating. All accessible elements and surfaces are electrically conductive.

The two Stäubli TX90L ESDs in the line’s two test cells have consistently proven that in complex handling processes, their performance is in no way inferior to that of standard robots. Using these machines guarantees maximum process reliability and prevents damage to electronic components. The six-axis robots manage handling of the PCBs in the test cells and make a decisive contribution to maintaining the entire line’s short cycle times and high availability.