- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

SUCCESS STORY

Making short work of crumbly products

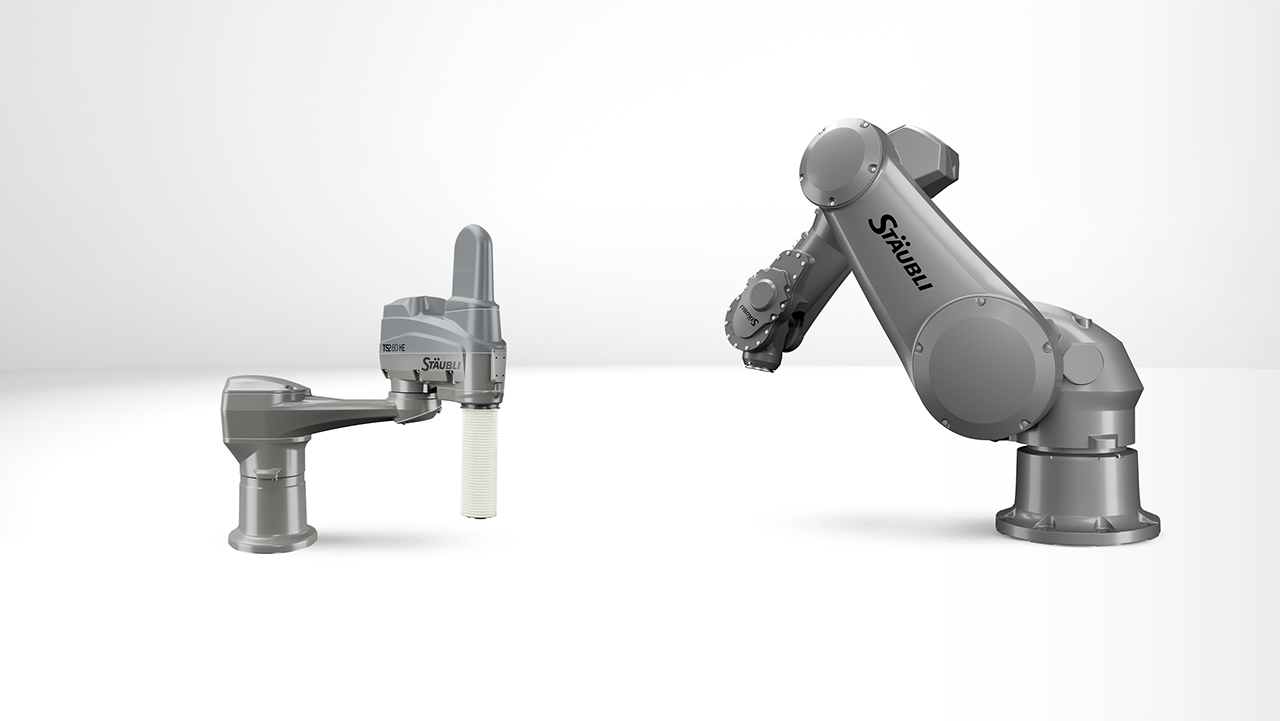

The speed and reliability of these robots makes them well-suited to the conditions of the ready-made foods industry. Stäubli’s TX90L HE robot can easily handle the delicate products and consecutive cleaning cycles involved.

CUSTOMER BENEFITS

- Cost-effective, highly productive solution

- High reliability of the robots despite adverse operating conditions

- Short cycle times, high output

- Strict compliance with hygiene requirements

TASK

Packaging of fish sticks

The standard pack of 15 breadcrumb-coated fish sticks is a classic in the frozen products range. In order to stay competitive within tight margins, seafood specialist TST opted for automation throughout with Stäubli industrial robots.

TST (The Seafood Traders) is committed to the volume production of fish products at the best possible price. A prerequisite for this is rapid processing, which is no longer conceivable in the food sector without automation. The value chain of the seafood specialist starts with sawing frozen blocks of raw fish and then continues through baking, coating with breadcrumbs and freezing, culminating in the packaging of the finished products.

One particular challenge is the packaging of fish sticks. Even in a frozen state, these natural products with their bread coating are crumbly to the touch and can push any automated system to its limits. For the realization of a robot-based packaging line, TST called on the services of ECONO-PAK in Flonheim, an equipment manufacturer specializing in the primary packaging of foodstuffs.

SOLUTION

Criteria only manageable with Stäubli robots

At the planning stage, it soon became apparent that a linear system with a sideload cartoning machine would be the right way to optimize the cycle times for getting the finished products packed in boxes. The sorting and grouping of fish sticks beforehand was to be handled by six-axis robots. However, the specified capacity of five tonnes of fish per hour and per packaging line proved to be an impossible challenge for almost all of the robot manufacturers consulted. Only Stäubli Robotics was able to guarantee that its high-speed six-axis robots (Type TX90L) working in shifts around the clock would be up to the task.

The Stäubli TX90L HE also scores top marks for its enclosed construction with internal cabling and the fact that it has been specifically designed for humid environments (hence the HE suffix). It therefore does not require any additional protective cover to comply with the strict hygiene regulations in the food industry and with all the other requirements for use in direct contact with frozen products. Four Stäubli TX90L HE robots work in concert on each of the two packaging lines for high-grade fillets and fish sticks. They form the core of the automated systems, assuming responsibility for grouping prior to packaging – five gourmet fish fillets or 15 fish sticks depending on the line. Each robot handles the contents of one package, and does so 50 times per minute.

The robots are tasked with moving the fish sticks in batches of 15 off the four belts onto a centrally located product cassette belt which leads to the packaging station. The four robots are capable of shifting 3,000 fish sticks per minute, enough for packing into 200 cardboard boxes. The synchronization of the robots with the fast-moving product cassette belt is effected by means of rotary encoder signals in the conveyor tracking process and works well even at the relatively high belt speed of 30 meters per minute.

CUSTOMER USAGE

High output while complying with hygienic standards

With these systems, TST achieves excellent output at high speed despite the problematic handling properties of the product. The target figure of five tonnes of fish per hour and packaging line is consistently maintained under normal operating conditions.

Strict mandatory hygiene standards require an approximately two-hour cleaning cycle of the packaging line performed once per day, which involves the use of cleaning substances with pH values ranging from 2 to 10. With their smooth surfaces, stainless steel components and special seals, the HE-spec Stäubli robots suffer no ill effects from the aggressive chemical compounds or the high-pressure jet washing.

At TST, they are highly satisfied with the quality of the robots as well as with the speed of response from Stäubli Robotics and ECONO-PAK. The total output of up to 300 tonnes of fish per day in three-shift operation also meets expectations. Almost all large supermarket chains and discounters stock TST products under different brand names in either cardboard box or plastic pouch format.