- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

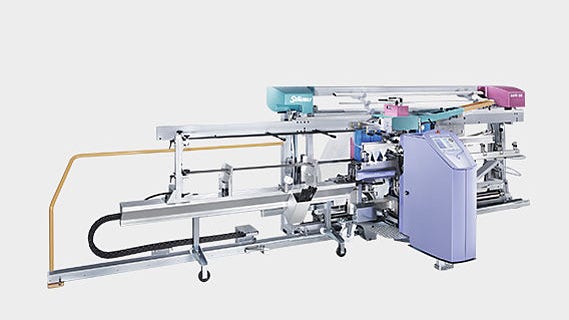

SAFIR S80 for complex 2-beam applications

The SAFIR S80 automatic drawing-in system is the right choice for the production of fabrics that are highly complex in terms of color & material and made using one or two warp sheets, such as seersucker fabrics for clothing or bed linens. This system gives users the possibility of creating the most complex weave structures with e.g. multiple yarn materials in up to 4 yarn layers – while simultaneously meeting the highest quality standards for the drawn-in weaving harness.

Consisting of a stationary drawing-in machine and one, or, as a rule, two mobile drawing-in trucks, the system draws the yarn into the reed, drop wires, and healds with up to 28 weaving frames – fully automatically and exactly according to the repeat. The machine control takes over the transport of the mobile drawing-in trucks during the drawing-in process. The final product is the warp with yarn sheet completely drawn into the healds, drop wires, and reed.

This system design provides very high drawing-in performance and, most importantly, error-free drawing in.

Main features of the SAFIR S80

- Optimal ergonomics, pictograms, and context-sensitive assistance messages support operating personnel in handling and programming.

- The system can be individually configured and forms the heart of the drawing-in department.

Yarn types

- Cotton and blended yarns (carded, combed)

- Wools (worsted yarns, woolen yarns)

- Silk, mono- and multifilaments

- Special yarns on request (e.g. ribbons, knop yarn, bouclé yarn)

- 3–250 tex, Ne 197–2.4, 30–2,500 dtex, 27–2,250 den, Nm 333–4

Stäubli also offers you...

-

SAFIR S32 drawing-in machine

The SAFIR S32 automatic drawing-in machine is perfect for weaving mills that process filament yarns. -

SAFIR PRO S47 high-speed drawing-in machine

The SAFIR PRO S47 high-speed automatic drawing-in machine is the ideal solution for mills producing a variety of standard applications. -

SAFIR PRO S67 high-speed drawing-in machine

The SAFIR PRO S67 high-speed automatic drawing-in machine is designed for universal use in producing various fabric types of medium complexity. -

TIEPRO warp tying machine

The TIEPRO warp tying machine is dedicated to operating standard yarn types. -

Cam motions series S1600 and S1700

Positive cam motions for weaving basic weaves from plain weaves to heavy fabrics in rapier and air-jet weaving machines. -

Rotary dobby series S3000

High-speed electronically controlled rotary dobbies for all types of patterned fabrics in water-jet, air-jet or rapier weaving machines depends on the application.