- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

SUCCESS STORY

State of emergency in the cell

For deburring and cleaning vehicle components, German cleaning specialist Maschinenbau Silberhorn uses Stäubli HE robots specially designed for applications in humid environments and wet spray areas.

CUSTOMER BENEFITS

- Short process times

- Easy deburring of hard-to-reach areas

- Highly reliable under extreme conditions

- Deburring and cleaning in one step

TASK

Deburring and cleaning vehicle precision components

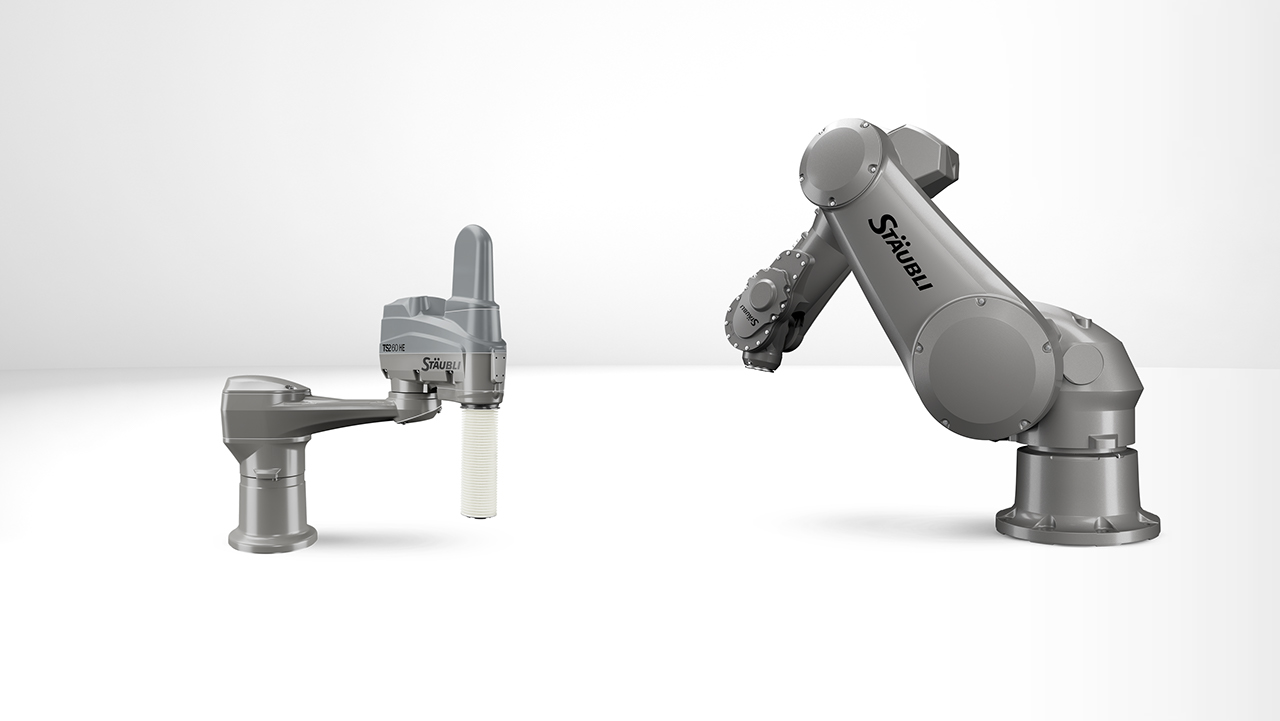

Innovative robotic deburring cells use waterjets at up to 2,000 bar to simultaneously deburr and clean vehicle components. Plants rely on Stäubli six-axis HE robots, which are perfectly designed to handle the tough conditions in the cell.

Maschinenbau Silberhorn has made a name for itself in the development, design and production of systems used in high-pressure waterjet deburring, cleaning and electroplating. Silberhorn's most popular products include the REZ automated deburring cells, which are mainly used in the automotive industry for deburring workpieces with a technically complex geometry.

Depending on the material, the machines can debur aluminum at pressures of 300 bar and stainless steel parts at up to 2,000 bar.

SOLUTION

Parts handling by robots under extreme conditions

The job of the robot is to handle the parts. The six-axis model picks up the waiting components, moves them along a precisely predetermined path to facilitate deburring and cleaning by the high-pressure waterjet, and then returns them to the production line. Working in the cells is a tough job for the robots. At water pressures of up to 2,000 bar, the conditions in the cell are extreme. The amount of kinetic energy just in the waterjet that bounces off the deburring part is phenomenal. When programming the course, you must always ensure that the robot's wrist never crosses the waterjet and is largely protected from side impacts.

To ensure maximum flexibility of the cells, several deburring tools can be installed in the deburring chamber, so that the only setup needed is to select the program in the control panel. All parts of the system are made of stainless steel. Depending on the size of the system, either a Stäubli TX90 HE or the larger RX160 is used. The suffix HE stands for Humid Environment and refers to Stäubli models extensively modified for applications exposed to spray water.

CUSTOMER USAGE

Deburring and cleaning in one step

Deburring with a high-pressure waterjet has two key advantages: even in difficult-to-reach locations such as deep drill-holes and blind holes, components can be effectively deburred compared to conventional methods and at the same time, cleaned to a high standard due to the high kinetic energy of the waterjet. A minimal amount of chemical additive improves the cleaning effect and prevents corrosion on the components.

For the robots, it is and remains a real endurance test. The machines are often expected to function perfectly for years in their stainless steel cells, working to a 3-shift cycle under 100% humidity and constant exposure to spray water. The HE robots from Stäubli are the only way to guarantee high availability and process reliability under these conditions.

The HE models are designated protection class IP65 as standard, which can be further enhanced by the use of a Stäubli overpressure unit. The robot's wrist is rated as IP67 and can be immersed in liquids. Then there is the vertical cable bushing which ensures all connections are located under the base of the robot and therefore protected from spray water.