- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

Plastics

Solutions and applications for the plastics industry

To remain competitive and conquer new markets, plastics processors design and manufacture products with a high added value. They are increasingly integrating automated operations during the press cycle time and seeking to reduce mold change times.

Compatible with clean environments and offering simple, easy and compact integration, the Stäubli range of four and six-axis robotic arms is specially designed for the plastics industry. Our robots thus play a role in increasing the added value of the product.

Features and benefits

Performance

Stäubli plastics robots are the fastest 6-axis robots on the market in terms of speed and acceleration (for example, 0.8 second demold time inside a 4-second cycle).

Cleanliness

Class 100 comes standard.

Flexibilty

Simply re-program the robot when the mold changes, and fully utilize the machine’s capacity by grouping various molds together. Our plastics robots can easily be integrated and moved to other injection molding machines (IMMs). New molds or processes are easily accommodated by our extensive plastics range.

Success stories

-

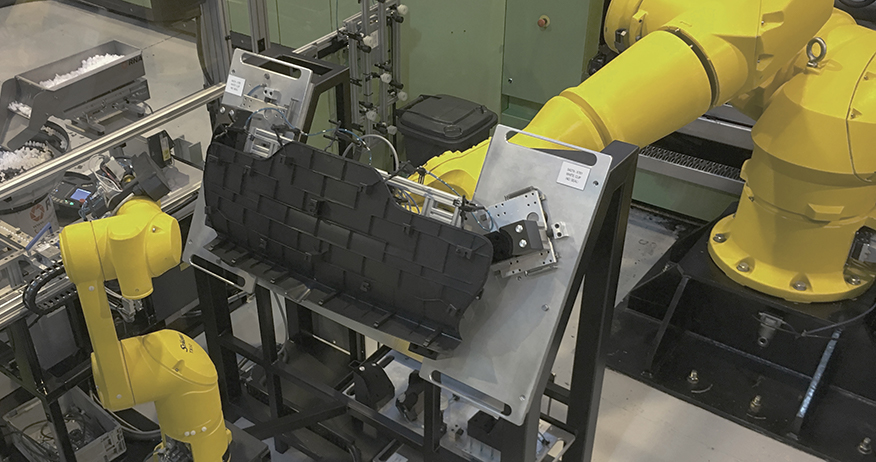

Processing of injection-molded parts

A British plastics processor has invested heavily in the full processing of components by robots alongside the presses. The concept has been so successful that the robot is now part of the package with every new injection molding machine ordered. -

Automation of injection molding machines with mobile robotics solution

The production of injection molding machines is automated with the help of Stäubli mobile robots, that can lift up to 80 tons. -

A robotic solution to guarantee hygiene and quality

Thanks to Stäubli, Plastibell is meeting the most stringent standards in terms of hygiene, traceability and quality across the entire production process. -

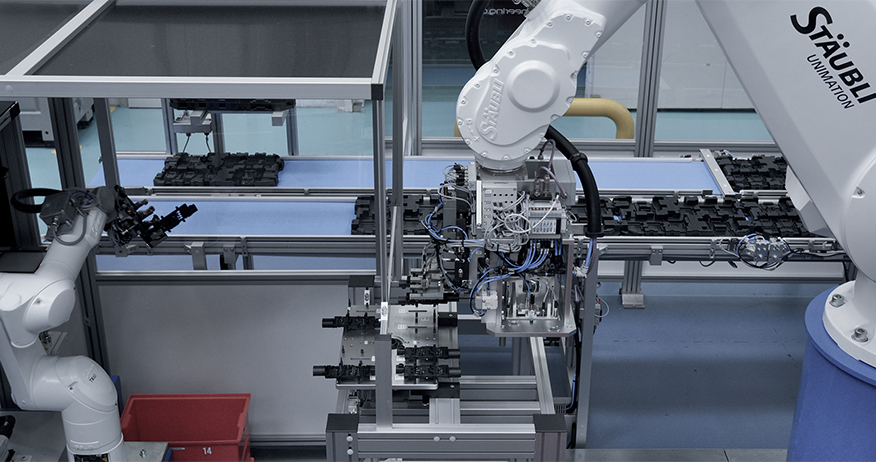

Production of sensors & PCB

For the overmolding of an electronic circuit board, specialist plastics manufacturer Adatis has opted for full automation with Stäubli industrial robots. In this way, the company can continue producing in the high-wage economy that is Switzerland. -

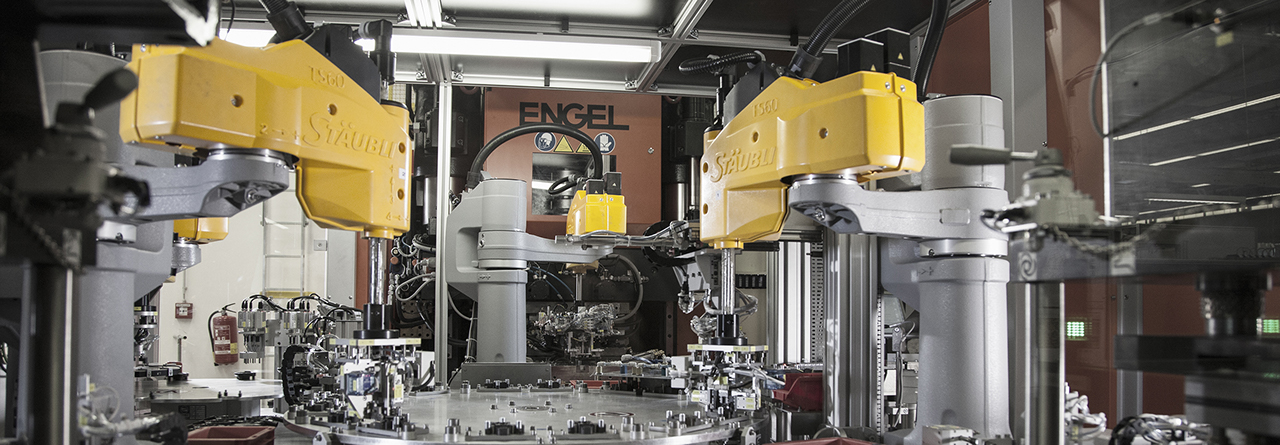

Production of oil level sensors

Four Stäubli SCARAs prove their worth in the production of oil level sensors. These highly dynamic four-axis machines pick up punched parts and connectors, insert metal parts, remove the finished injection-molded parts and clear away the sprue. -

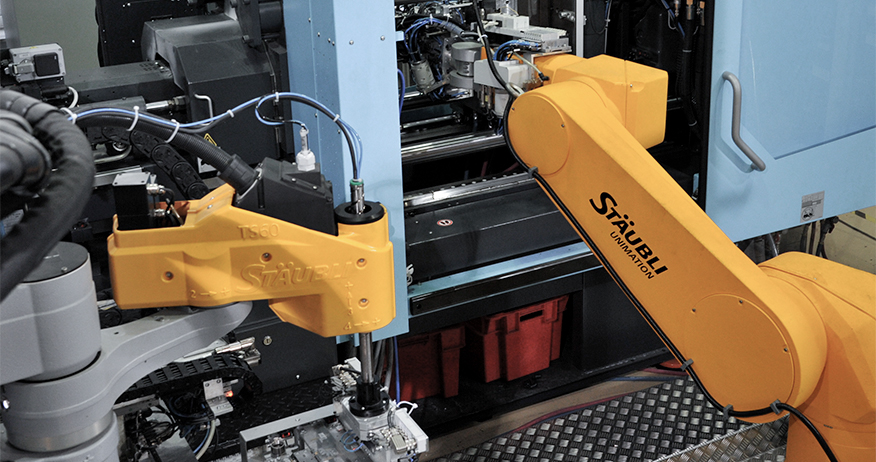

Production of brake light switches

Automotive supplier TRW produces eight million brake light switches a year for Volkswagen Group. To optimize production, TRW turned to Stäubli for its expertise as well as its TS60 SCARA and RX160 6-axis robots, two ultra-high-precision robots. -

Additive manufacturing Fiber Patch Placement (FPP)

The Fiber Patch Placement (FPP) systems developed by a Bavarian technology company constitute a step change in additive manufacturing. Thanks to high-performance robotics, the process has the potential to revolutionize the series production of geometrically complex lightweight parts in the automotive industry. -

Processing exterior parts

While the development of composite exterior parts for vehicles takes place on computer systems, production is still dominated by manual labor. An Austrian manufacturer has made the switch to robot processing and is delighted with the results. -

Robot-assisted machining of CFRP parts

A Spanish manufacturer of lightweight components for motor racing was reaching the limits of what could be achieved with its existing three-axis machine. The solution, which adds flexibility, cost-effectiveness and design freedom, came with the purchase of a Stäubli robot. -

Coating headlamp lenses

Currently, all plastic headlamp lenses come with a protective coating. Thanks to the latest generation of robots, transparent micrometer-thin protective layers can be accurately applied under cleanroom conditions.