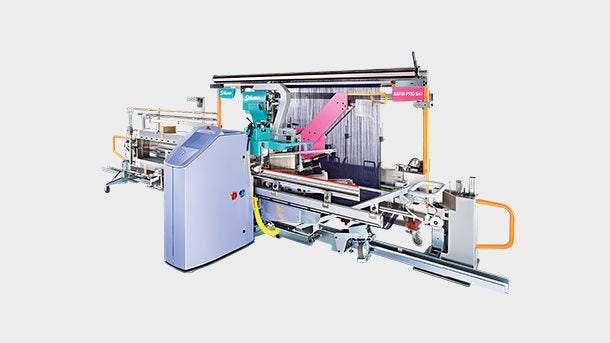

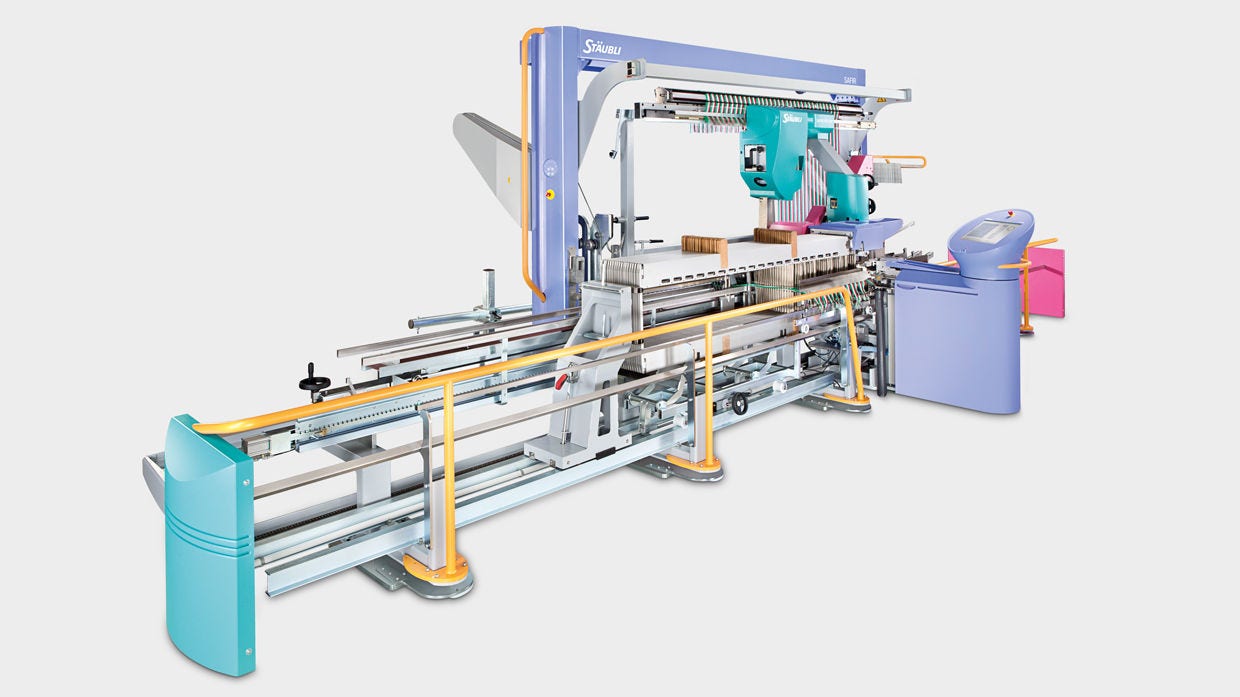

High-speed automatic drawing-in machine for filament applications - SAFIR PRO S37

The SAFIR PRO S37 automatic drawing-in system is ideal for processing filament yarns to make fabrics for awnings, leisure wear, and linings as well as technical textiles.

Consisting of a mobile drawing-in machine and one or ideally more stationary drawing-in stations, the system fully automatically draws the yarn into the reed and healds. SAFIR PRO S37 is available with up to 8, 12, or 16 heald carrier rods. The final product is the warp with yarn sheet completely drawn into the healds and reed. Using a suitable harness truck, the compact unit is transported to the weaving machine and laid in or temporarily parked in a storage area.

This system design provides very high drawing-in performance while allowing maximum flexibility in the placement of the system within the existing space. Adaptation to the material flows within the mill is optimal.

Main features of the automatic warp drawing-in machine SAFIR PRO S37

- Whether at top speed of 280 cycles per minute or in non-stop 24/7 operation – the drawing-in machine SAFIR PRO S37 delivers constantly perfect results.

- Optimal ergonomics, pictograms, and context-sensitive assistance messages support operating personnel in handling and programming.

- The system can be integrated into any weaving mill. The space requirements are minimal, and the system can be optimally positioned in a variety of set ups.

- For 2-beam filament applications, a Layer- & Offset Management option with four clamping rails is available; supporting highest performance in the warp processing.

Yarn types

- Multifilaments and fine monofilaments, tecnical yarns like glass

- 0.8-250 tex, 8-2’500 dtex, 7-2’250 den

Main features

Solution for double warp beam applications

Stäubli Textile also offers you...

-

SAFIR PRO S47 high-speed drawing-in machine

The SAFIR PRO S47 high-speed automatic drawing-in machine is the ideal solution for mills producing a variety of standard applications. -

SAFIR PRO S67 high-speed drawing-in machine

The SAFIR PRO S67 high-speed automatic drawing-in machine is designed for universal use in producing various fabric types of medium complexity. -

SAFIR S80 drawing-in machine

The SAFIR S80 automatic drawing-in machine is the perfect solution for manufacturing complex fabrics woven with 1 or 2 warp beams. -

TIEPRO warp tying machine

The TIEPRO warp tying machine is dedicated to operating standard yarn types. -

TOPMATIC warp tying machine

The TOPMATIC warp tying machine supports operating versatile and finest yarn types. -

MAGMA warp tying machine

The MAGMA warp tying machine is the ideal solution for coarse and technical yarn types.