- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

Denis & Fils masters challenges of the future with the SX PRO Jacquard machine

Denis & Fils was established near Lyon in 1956 and is now being run by the third generation. Originally a silk manufacturer, the company has become a prestigious weaving workshop that specializes in luxury textiles for women's clothing and top French fashion brands. The beautiful fabrics are woven in silk, wool and cotton.

The challenge

Chairman Bruno Denis is proud of the company’s heritage and its rise to success: “Stäubli has accompanied us throughout our journey, and the arrival of a new Stäubli machine has always been an auspicious event. We received our first Stäubli machine in 1987, when I was only eleven years old. We were in awe of its capabilities. Two years later, in 1989, a famous French design house entrusted us with weaving their collection, which allowed us to enter the luxury market.” Denis & Fils has relied on Stäubli machinery to meet the stringent demands of its luxury customers ever since. State-of-the-art, precision machinery is essential to handle the delicate and expensive yarns and avoid wastage. The machinery must be able to produce complex design patterns and offer great versatility in order to weave fine silks, delicate wools, and complex lamé threads into fabric collections of the highest quality.

Customer benefits

- Precise, high-quality weaving

- Allows complex designs and handles challenging fabrics

- Robust & resilient with easy maintenance for optimal production

- Higher power efficiency for reduced energy consumption

The solution

Denis & Fils is now counting on the new Stäubli SX PRO Jacquard machine to meet the next challenges of the future. Weaving Mill Manager Patrick Seyve explains the choice: “Not only does the SX PRO give us the highest quality and design versatility, it will lower our energy costs and optimize production time. Its robust, low-maintenance design, combined with NOEMI electronic data transmission and the user-friendly intuitive controller, will save us downtime and thereby dramatically reduce our operating costs.”

- Meeting the need of luxury apparel with a high performing machine

- SX PRO Jacquard machine – Respond to the need to reduce energy consumption in weaving mills

- Stop wasting raw materials thanks to the precision of the SX PRO Jacquard machine

What does the customer say?

"The new electronics have already been tried and tested on new formats which combine new modules that enable us to save energy, both mechanically, and in the hook selection system for the shed. All the strong points of the SX have been kept or improved. So this machine will certainly serve us for a long time and save us money in both energy and maintenance."

Patrick Seyve,

Weaving Mill Manager of Denis & Fils

Product solution for this type of application

-

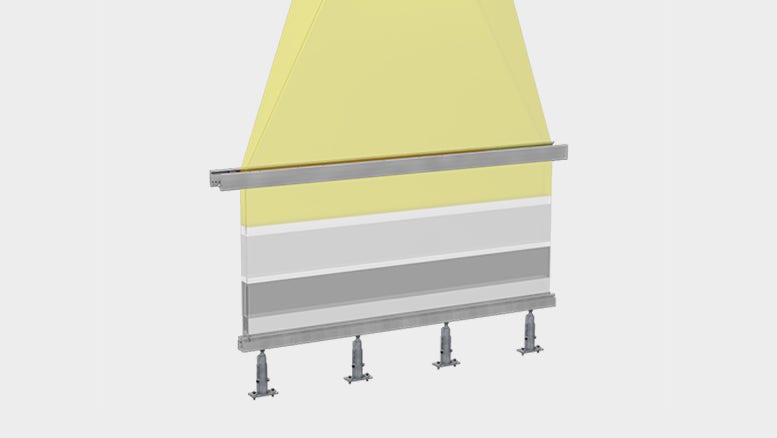

SX PRO Jacquard machine

Electronic Jacquard machine is ideal for weaving flat fabrics, terry cloth and technical fabrics on all types of air-jet, rapier and water-jet machines, up to 2,688 hooks. -

LX PRO Jacquard machine

The LX PRO electronic Jacquard machine is ideal for weaving terry cloth, silk fabrics, tapestry, fabrics for apparel, upholstery or car seat covers, and technical fabrics on all types of air-jet, rapier and water-jet weaving machines, up to 7,680 hooks. -

Harnesses

Stäubli high quality harnesses and harness accessories make the perfect link between the Jacquard machine and the warp threads of the weaving machine.