- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

Pharma offering

Dedicated industrial robots for each pharma grade environment

Our customers and leading pharmaceutical companies place trust in our solutions. This gives our engineers an advantage when adapting our well-known range of robots dedicated to pharma production environments.

Our 30 years of experience in the pharmaceutical market have enabled Stäubli to develop the widest range of 4- and 6-axis Stericlean and cleanroom robots on the market to meet the multiple constraints of the pharma market. Robots have become more and more popular due to their flexibility and to trends in personalized medicine and small batch production.

Our pharma offering includes the Stericlean range for aseptic environments and the Stericlean+ range, which address the ever-increasing demands of the pharma sector by providing validated solutions that meet the highest hygiene and cleanliness standards.

A robot in the industry is defined according to payload, reach and speed. In pharma, a fourth factor is also considered, related to the production environment and cleaning processes used on equipment. Stäubli offers flexible solutions in these market-specific areas.

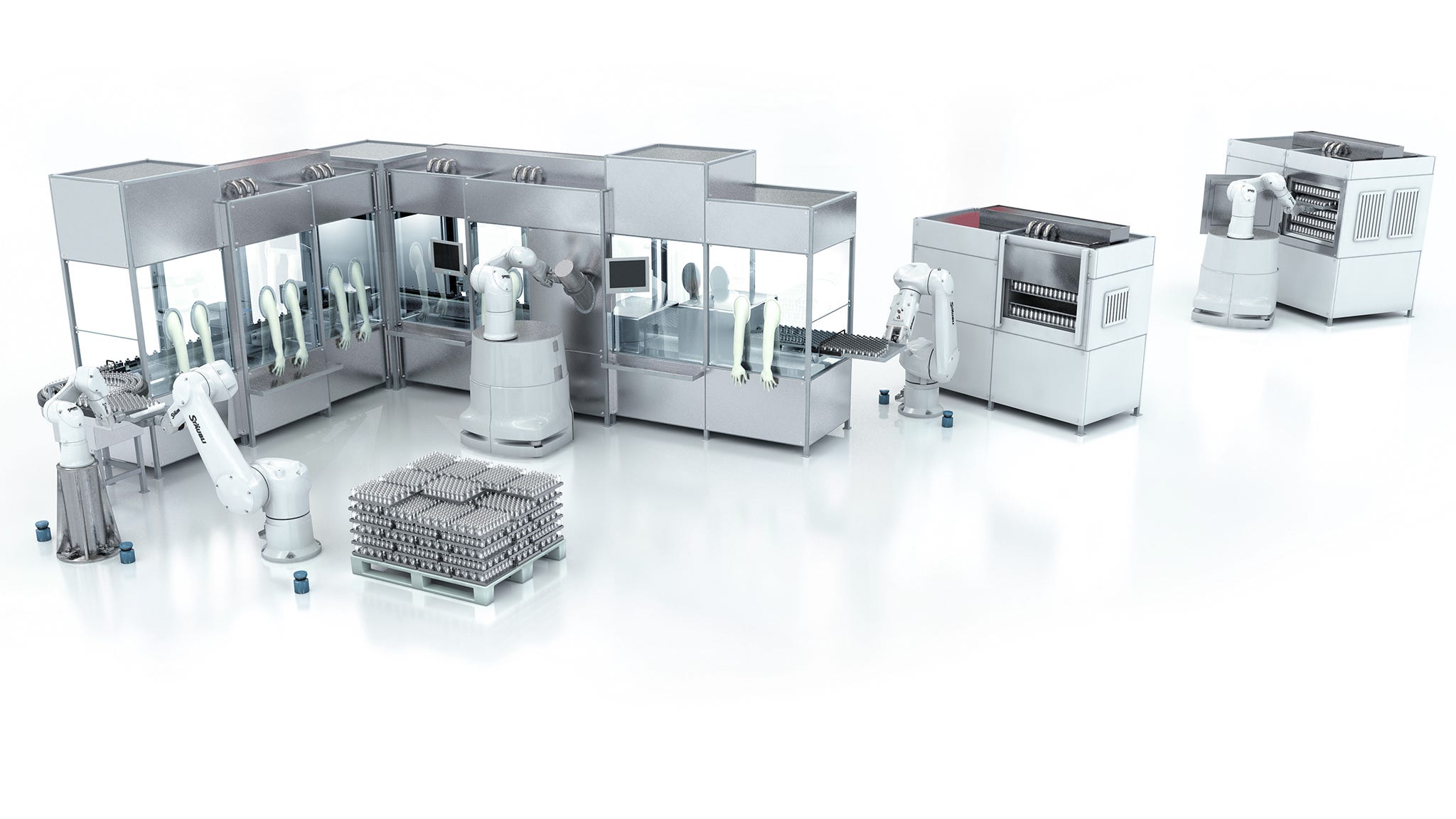

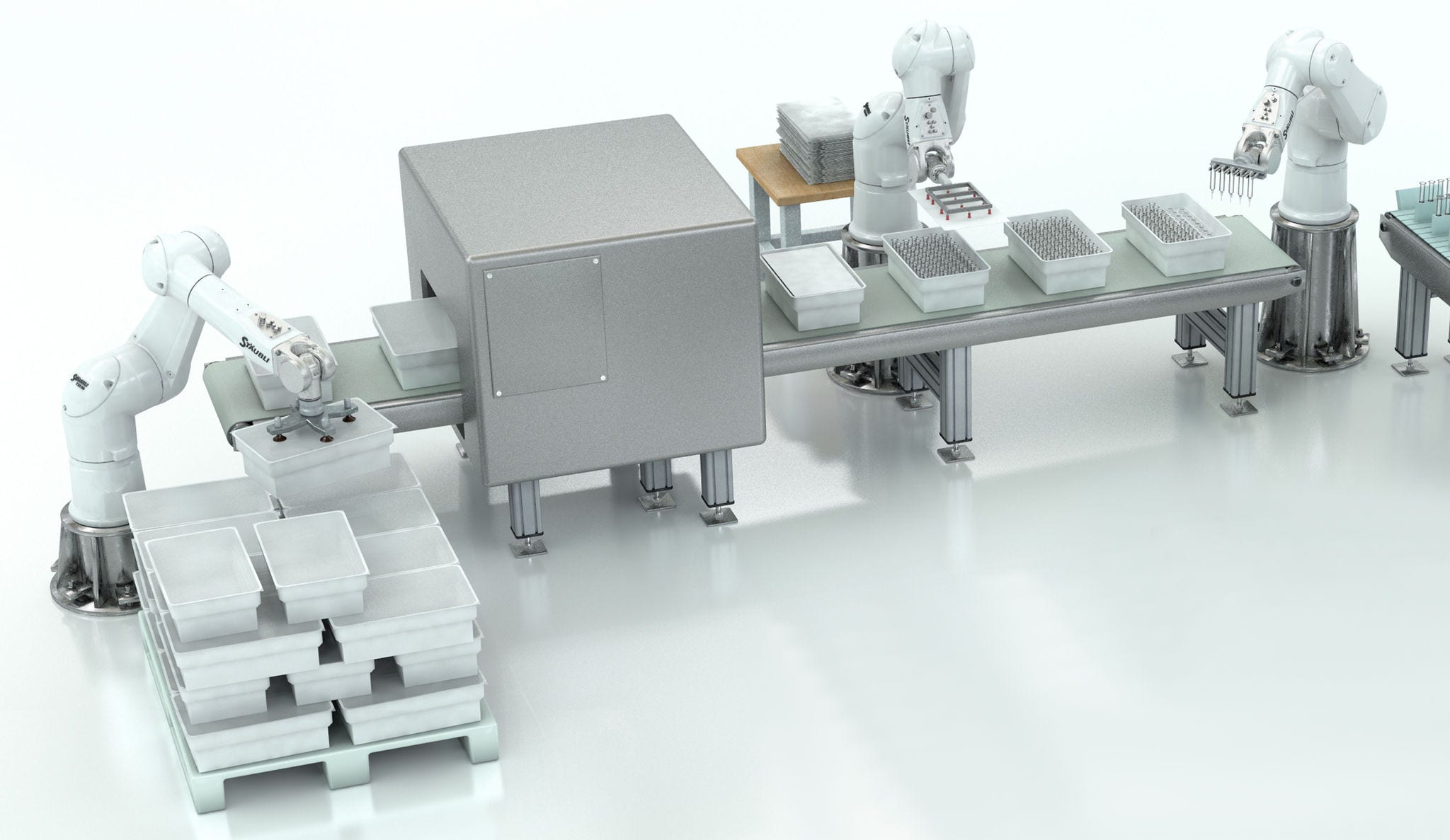

Pharma factory areas

A pharma factory is divided into several areas that require different specifications in terms of cleaning processes and particle emissions. Stäubli defines four levels of requirements, from the most restrictive, isolators in Grade A, subjected to aggressive H₂O₂ cleaning, to logistics areas, intermediate levels of inspection, RABs, and secondary packaging, where equipment is cleaned with alcohol wipes.

Isolator - Grade A (ISO5)

- Highly monitored fill/finish process lines of high potency and toxic drugs

- Highest hygienic standards in design, material and components

- Regular VHP cleaning

Vials filling by TX2-40 Stericlean+ within isolator

TX2-60 Stericlean+ placing filled vials into trays

RABS, freeze fryers and autoclaves - Grade A/B (ISO 5)

- Auxiliary process around isolators

- Hygienic design required

- May requires lower VHP concentration rates, liquid H₂O₂ cleaning or sterilization/decontamination with alcohol or other media

Loading isolator with empty containers. TX2-160 Stericlean robot taking the tray /Akylux box. TX2-40 pushing the product into the filling line.

Unloading of filled containers from isolator and moving to secondary packaging, autoclaves or freeze dryer

Secondary packaging - Grade C (ISO 6/7)

- Inspection and individual packaging

- Easy to clean design

- Generally requires disinfection with alcohol (IPA)

Palletizing by TX2-90 robot

TUBs loading by TX2-60

Final packaging - Grade D/E & CNC (ISO 8)

- Conditioning, cartoning & palletizing

- Sleek white robots with suitable pharma appearance

- Lower cleaning requirement

TX2-60 robot placing filled syringes into blisters.

Palletizing with TX2-160 robot, automated forklift moves pallet to logistics area.

Stericlean+

A unique hygienic robot range for aseptic processes in pharma

To stay in line with the new requirements, Stäubli partnered with SKAN, the world leader in manufacturing isolator systems, and specialized in pharma and aseptic environments.

„Through our SKANalytix service, we provide our customers with analytical support for their questions and concerns around aseptic processing“ Gregor Hommes, Head of Research and Strategic Business Development at SKAN.

The Stericlean+ is easily integrated in pharma automation thanks to its complete documentation, which supports the pharmaceutical industry in qualification of the entire machine. Stäubli offers a full range of validated robots including the documentation package required to ensure compatibility, safety and consistency and ease final acceptance of the entire machine.

Decontamination processes are key within the pharmaceutical sector, especially within an isolator environment. Stäubli and SKAN’s collaboration has resulted in the development of new features for the Stericlean+ package that ensure that the robots are suitable for aseptic manufacturing conditions.

Testing resulted in two major benefits. For Stäubli, greater progress in R&D design, and for clients, greater transparency about robot performance.

- V&D package

- Pharma offering robots

- Stericlean+ robots made for isolator

- Skan

Technical specifications

Coming soon...

Stericlean robot range

| 6 axis robots | ||||||

|---|---|---|---|---|---|---|

| Model |

|

|

|

|

|

|

| Degrees of freedom | 6 | 6 | 6 | 6 | 6 | 6 |

| Load capacity (kg) | 2 | 4.5 / 3.7 | 14 / 12 / 7 | 40 | 40 / 25 | 170 / 110 |

| Reach at wrist (mm) | 515 | 670 / 920 | 1000 / 1200 / 1450 | 1510 | 1710 / 2010 | 2209 / 2609 |

| Repeatability (mm) | ±0.02 | ±0.02 / ±0.03 | ±0.03 / ±0.035 / ±0.04 | ±0.05 | ±0.05 | ±0.045 / ±0.055 |

Cleanroom standard: ISO 14644-1 |

Class 4 Class 10 |

Class 4 Class 10 |

Class 4 Class 10 |

Class 4 Class 10 |

Class 4 |

Class 5 |

| GMP | Grade A/B | Grade A/B | Grade A/B | Grade A/B | Grade A/B | Grade A/B |

Protection class (*wrist) | IP65 (*IP67) | IP65 (*IP67) | IP65 (*IP67) | IP67 | IP67 | IP65 (*IP67) |

| Attachment methods | 360° mounting possibility | Floor or ceiling | Floor / Ceiling* | |||

| Stäubli controller | CS9 | CS9 HP | ||||

*Ceiling consult us

| SCARA robots | ||||

|---|---|---|---|---|

| Model |

|

|

|

|

| Degrees of freedom | 4 | 4 | 4 | 4 |

| Load capacity (kg) | 8.4 | 8.4 | 8.4 | 8.4 |

| Reach at wrist (mm) | 460 | 620 | 800 | 1000 |

| Repeatability (mm) | ±0.01 | ±0.01 | ±0.015 | ±0.02 |

| Stroke (mm) | 200 or 400 (option) | 200 or 400 (option) | 200 or 400 (option) | 200 or 400 (option) |

| Protection class | IP65 | IP65 | IP65 | IP65 |

| Attachment methods | Floor or ceiling | |||

| Stäubli controller | CS9 | |||

Stericlean+ robot range

| 6 axis robots | |||

|---|---|---|---|

| Model |

|

|

|

| Degrees of freedom | 6 | 6 | 6 |

| Load capacity (kg) | 2 | 4.5 / 3.7 | 14 |

| Reach at wrist (mm) | 515 | 670 / 920 | 1000 |

| Repeatability (mm) | ±0.02 | ±0.02 / ±0.03 | ±0.03 |

Cleanroom standard: ISO 14644-1 FS 209E |

Class 5 Class 100 |

Class 5 Class 100 |

Class 5 Class 100 |

| GMP | Grade A | Grade A | Grade A |

| Protection class | IP65 | IP65 | IP65 |

| Attachment methods | 360° mounting possibility | ||

| Stäubli controller | CS9 | ||

Available options | Stericlean H₂O₂ harness Hygienic box | ||