Robotic tool changer model overview

Robotic tool changing systems from the MPS product line are impressive due to their multifunctional technology applications and cover the entire bandwidth of customer-specific applications.

MODEL OVERVIEW

MODEL | MAX. PAYLOAD (kg) | MAX. STATIC MOMENT (Nm) | MAX. DYN. MOMENT (Nm) | PNEU. BALL LOCKING (MPa) | REPEAT-ABILITY (mm)

| OPERATING TEMPERATURE (°C) | HEIGHT (COUPLED, mm) | PITCH CIRCLE DIAMETER (PCD) ROBOT ADAPTER FLANGE | MODULE PLACES |

|---|---|---|---|---|---|---|---|---|---|

10 | 15 | 52 | 0.45 - 1.0 | 0.0015 | 0 - +50 | 46 | ISO 9409-1-31,5-4-M5 | 4 | |

20 | 34 | 119 | 0.45 - 1.0 | 0.0015 | 0 - +50 | 46 | ISO 9409-1-40-4-M6 | 4 | |

20 | 40 | 100 | 0.3 - 0.8 | 0.0015 | +5 - +60 | 46 | ISO 9409-1-50-4-M6 | 4 | |

35 | 80 | 280 | 0.35 - 1.0 | 0.0015 | 0 - +50 | 46 | ISO 9409-1-50-4-M6 | 6 | |

55 | 106 / 145 | 371 / 507 | 0.35 - 1.0 | 0.0015 | 0 - +50 | 46 | ISO 9409-1-63-4-M6 | 6 | |

MPS 080 | 80 | 286 | 1.001 | 0.45 - 1.0 | 0.01 | +5 - +60 | 67 | ISO 9409-1-80-6-M8 | 5 -10 |

MPS 130 | 100 | 800 / 900 | 2,800 / 3,150 | 0.45 - 0.8 | 0.01 | +5 - +60 | 67 | ISO 9409-1-100-6-M8 | 6 - 12 |

MPS 260 | 350 | 2,000 | 7,000 | 0.5 - 1.0 | 0.01 | +5 - +60 | 67 | ISO 9409-1-125-11-M10 | 7- 14 |

MPS 260S | 350 | 2,500 | 8,750 | 0.5 - 1.0 | 0.01 | +5 - +60 | 67 | ISO 9409-1-125-11-M10 | 7 - 14 |

MPS 631 | 630 | 3,200 | 11,200 | 0.45 - 1.2 | 0.01 | 0 - +50 | 100 | ISO 9409-1-160-11-M10 / ISO 9409-1-160-11-M12 / ISO 9409-1-200-11-M12 / ISO 9409-1-200-12-M12 / ISO 9409-1-200-11-M16 / ISO 9409-1-200-12-M16 / | 5 - 14 |

MPS 631S | 630 | 5,000 | 17,500 | 0.45 - 1.2 | 0.01 | 0 - +50 | 100 | ISO 9409-1-160-11-M10 / ISO 9409-1-160-11-M12 / ISO 9409-1-200-11-M12 / ISO 9409-1-200-12-M12 / ISO 9409-1-200-11-M16 / ISO 9409-1-200-12-M16 / | 5 - 14 |

MPS 1531 | 1,530 | 15,000 / 12,500 | 37,500 / 30,000 | 0.45 - 1.2 | 0.01 | +5 - +60 | 100 | ISO9409-1-200-12-M12 / ISO9409-1-200-12-M16 | 7 - 14 |

| MPS 2531 | 2,500 | 33,000 / 44,000 | 66,000 / 110,000 | 0.45 - 0.8 | 0.01 | +5 - +60 | 110 | ISO 9409-1-315-16-M16 | 10 - 20 |

Related products

This might interest you

-

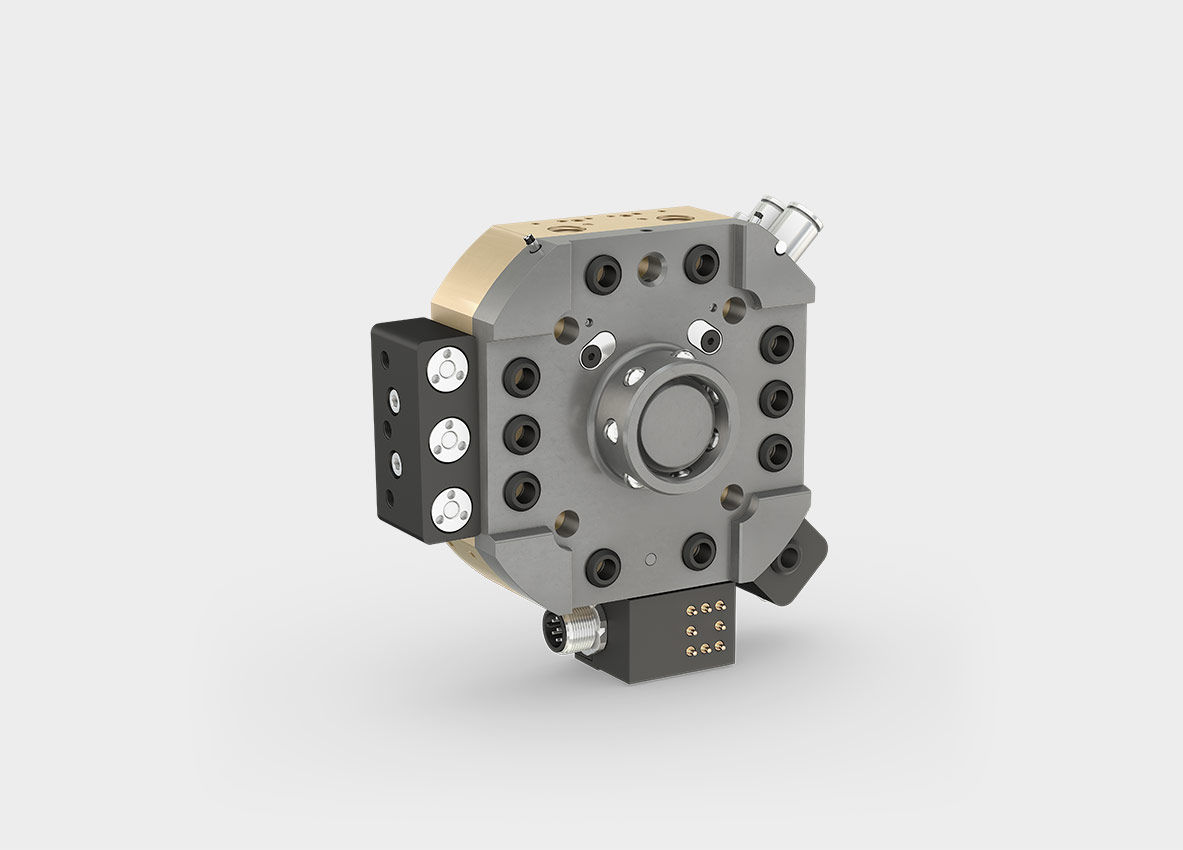

MPS Small payload

Models by payload: 10 kg / PCD31.5 20 kg / PCD40 20 kg / PCD50 35 kg / PCD50 55 kg / PCD63 -

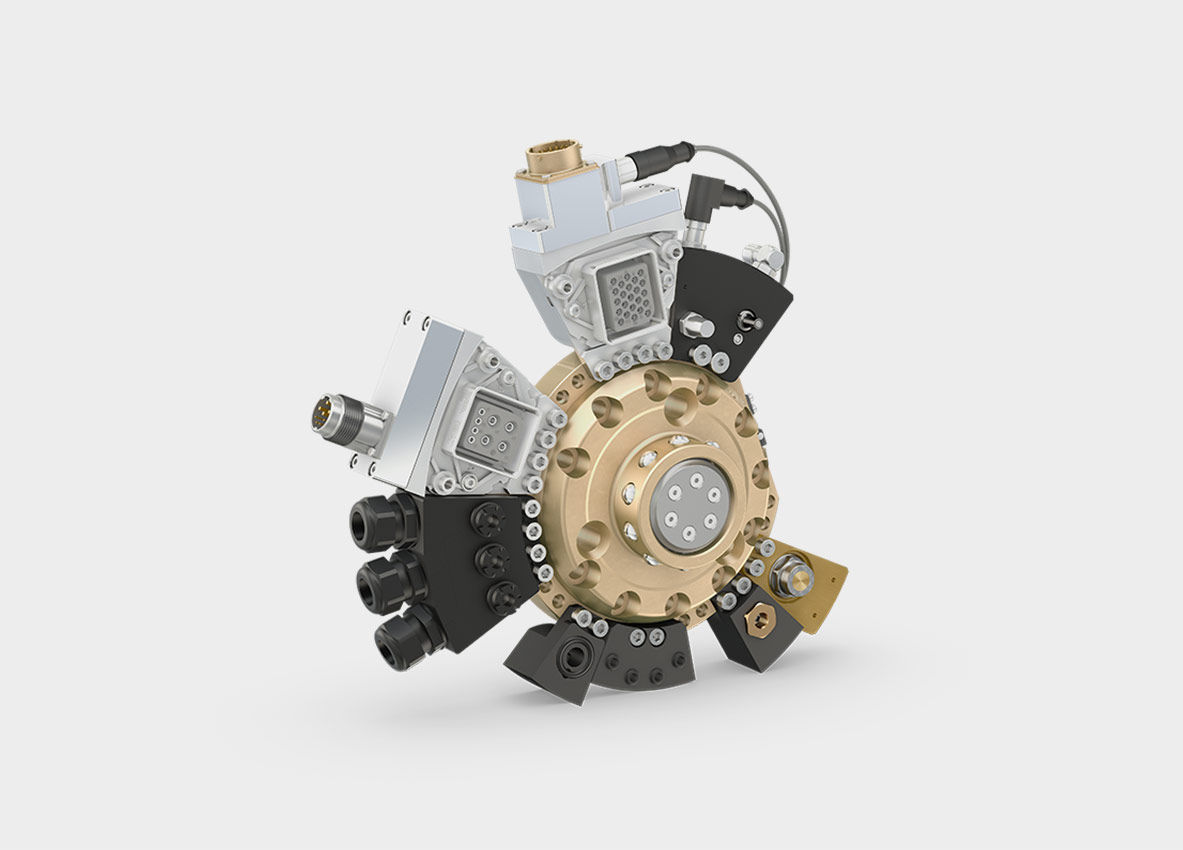

MPS Medium payload

Models by payload: 80 kg / PCD80 100 kg / PCD100 350 kg / PCD125 -

MPS High payload

Models by payload: 630 kg / PCD160 630 kg / PCD160 + 200 1530 kg / PCD200 2500 kg / PCD315