- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

- PLASTICS

- WHITE PAPER

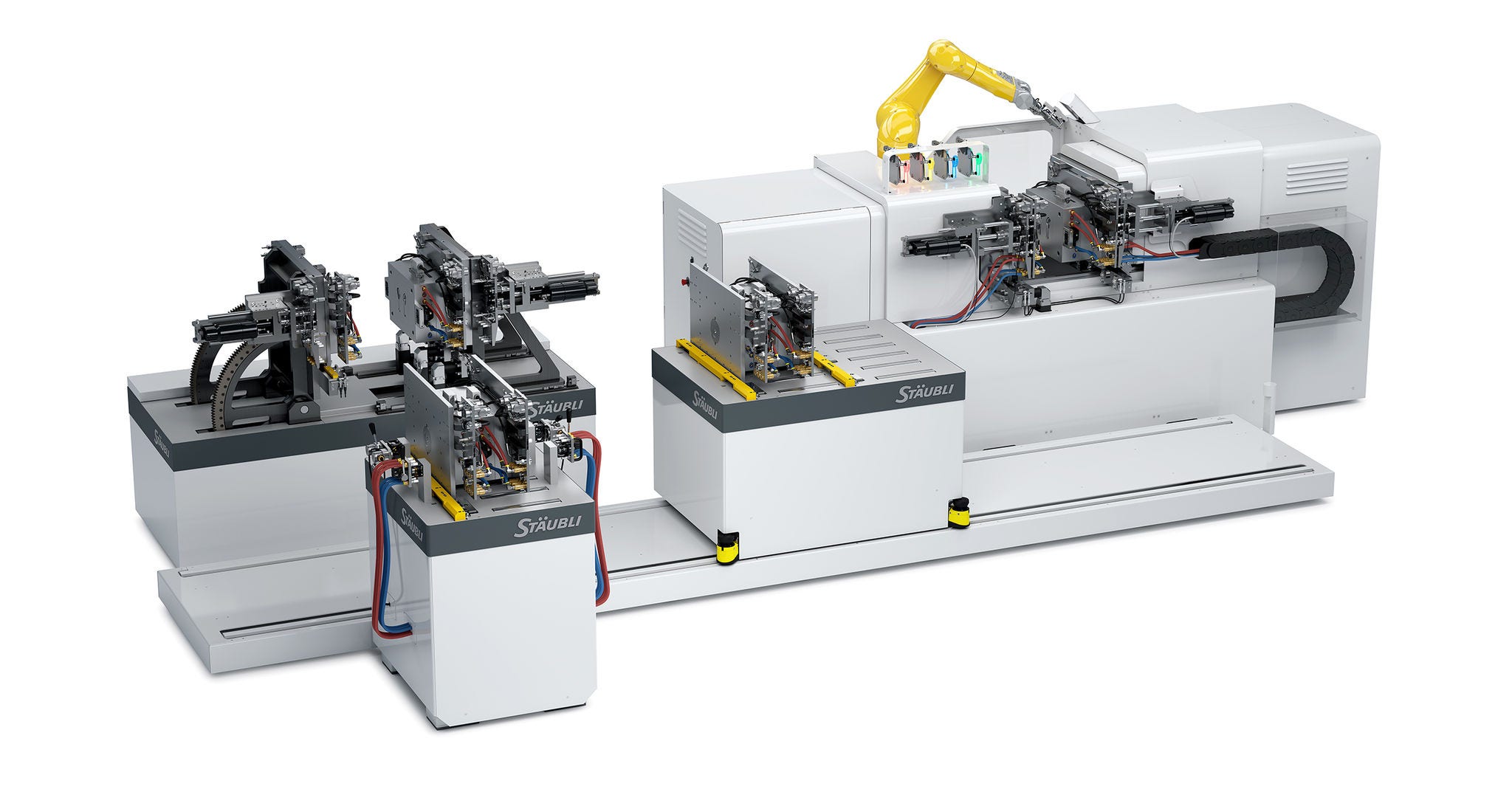

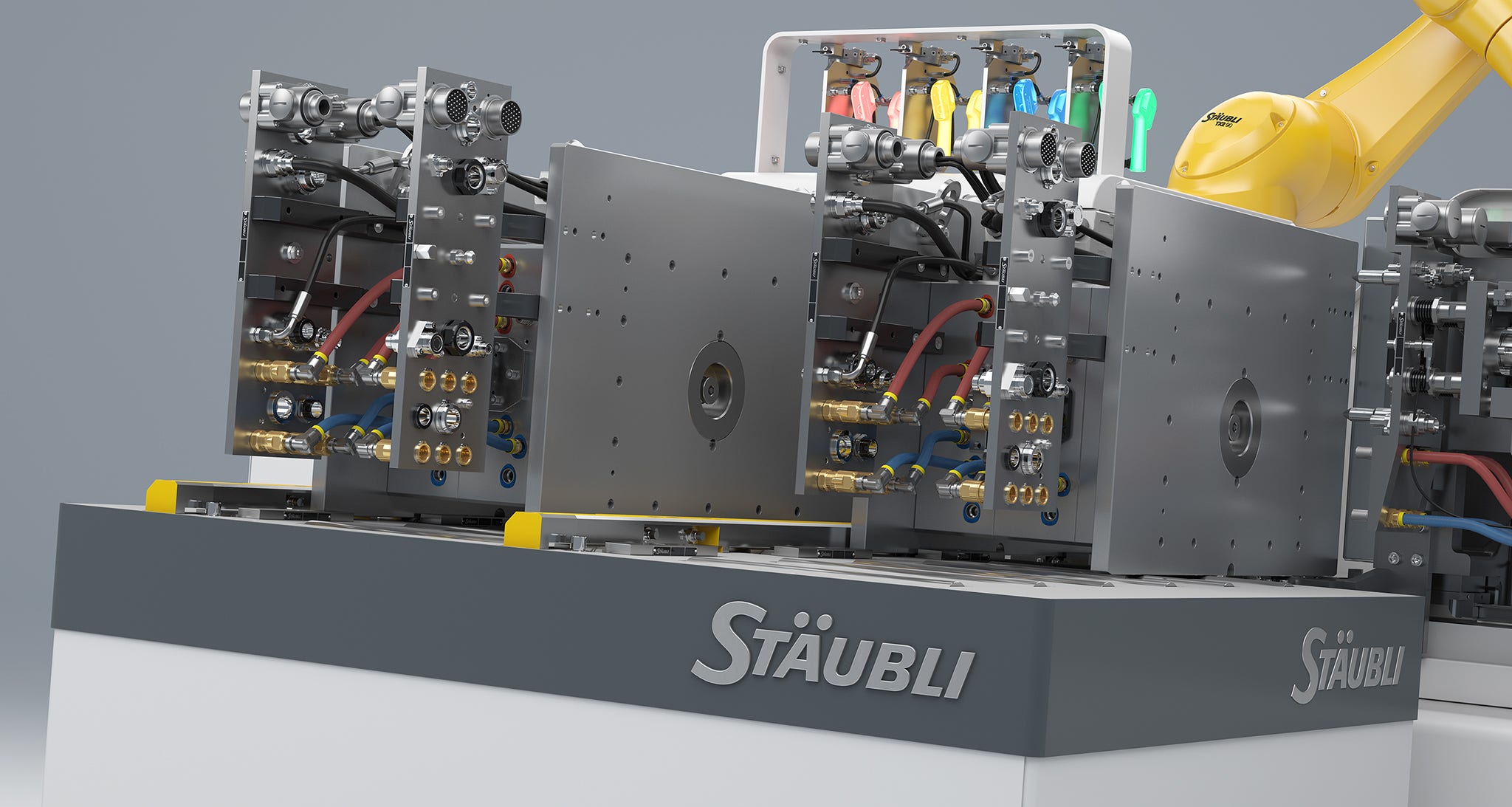

Quick Mold Change solutions for the plastics industry

Reducing the time taken to change a die is fundamental to the SMED process — Single-Minute Exchange of Dies. Process automation, performance, reliability and innovation are the main criteria detailed in the QMC (Quick Mold Change) solutions from Stäubli in its quality program and productivity optimization.

These considerably reduce downtime and offer a much needed and flexible approach to frequent die changes, cost reduction, time wasted and stock redudancy.

Stäubli’s expertise in loading and mold clamping, energy connection, and robotic systems for the plastics industry mean we can offer targeted or global solutions.

SMED Analysis

Mold change times are synonymous with unproductive times. Solutions allow them to be reduced to a minimum.

Applications

- Mold connecting

- Mold clamping

- Mold loading

- Mold inspection

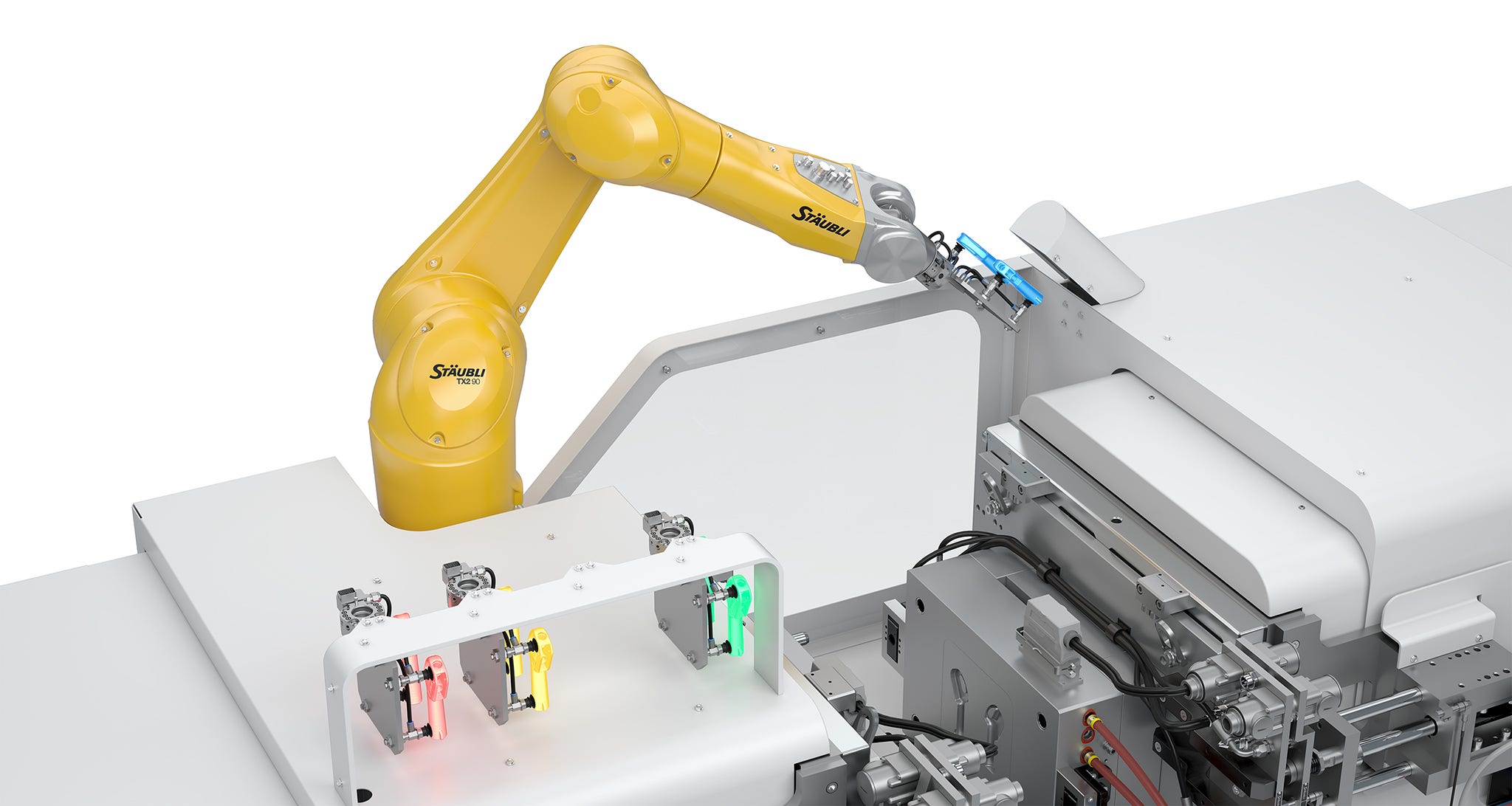

- Robot tool changer

Product finder

Watch our videos - Expert minutes

Overall automatized solutions | Mold change in single minute

Mold inspection

Stäubli workstations make it easier and safer to work on very large molds.

Parts handling

With increasing demands for multiple mold changes, flexibility is essential for remaining competitive. For robotic industrial processes, modular solutions allow the robot to change tools in a fully automated and timely manner.

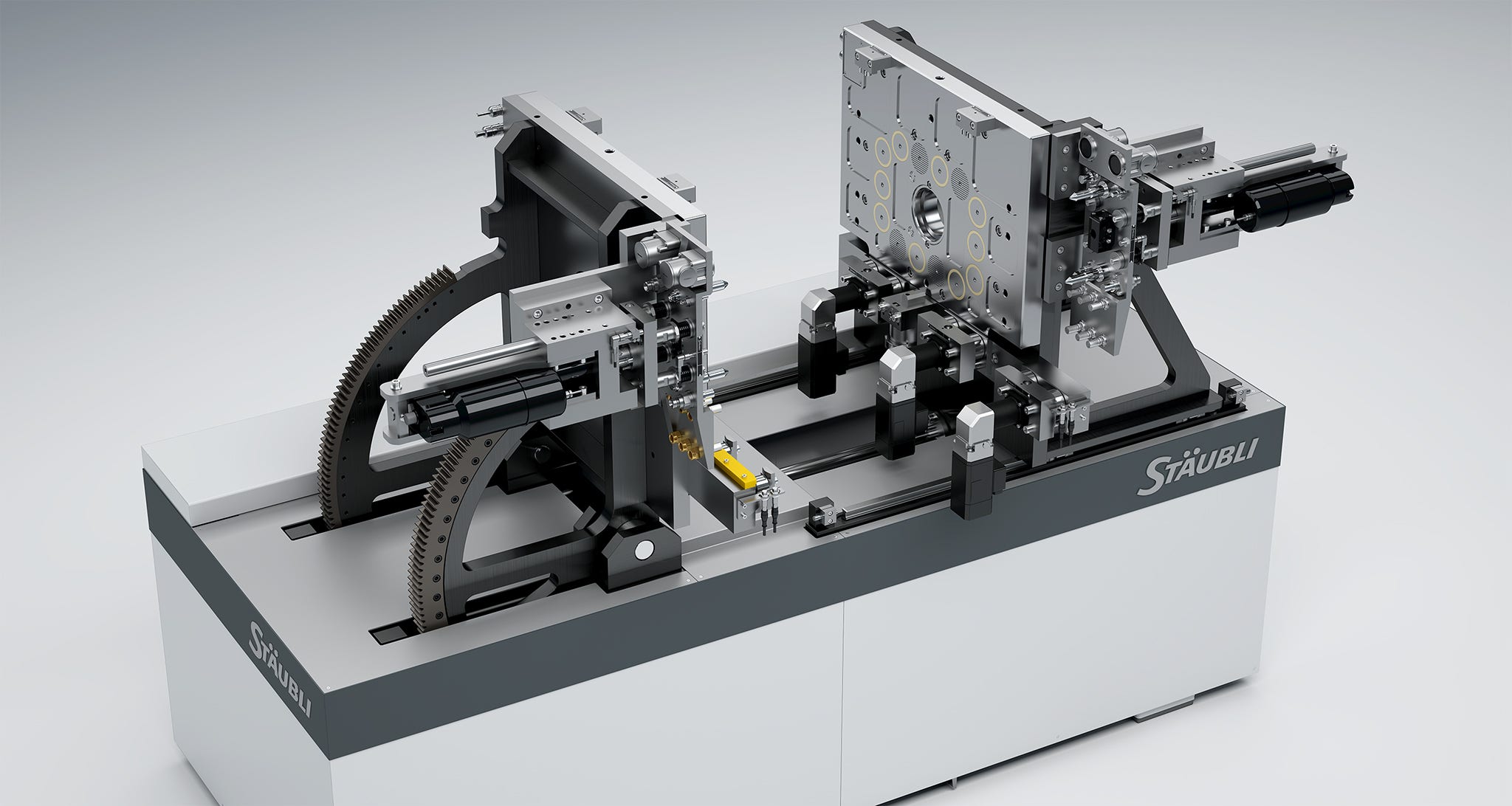

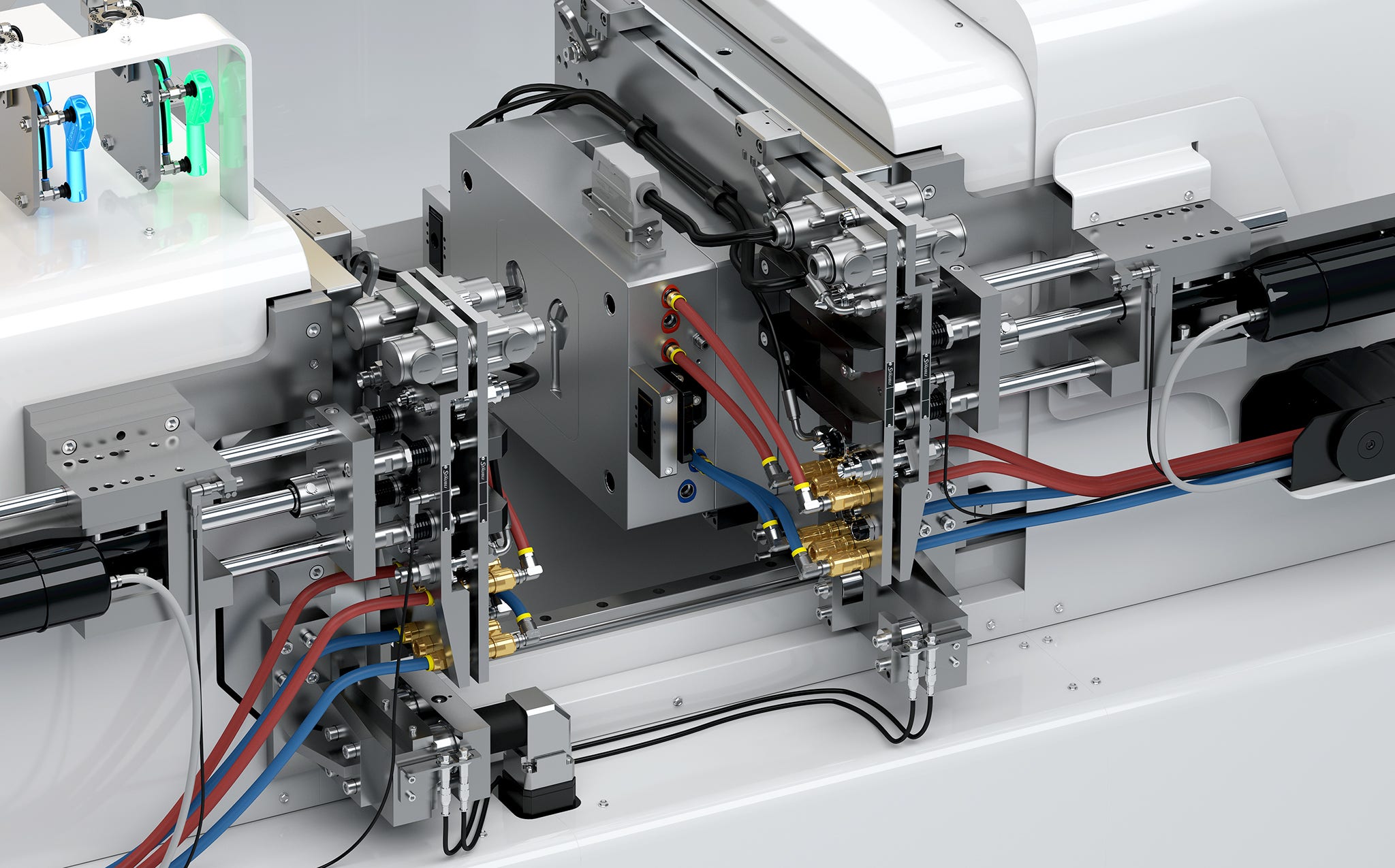

Mold transfer and loading

Fixed workstations and shuttle carts: customized solutions according to the specification of tools, machines and production processes.

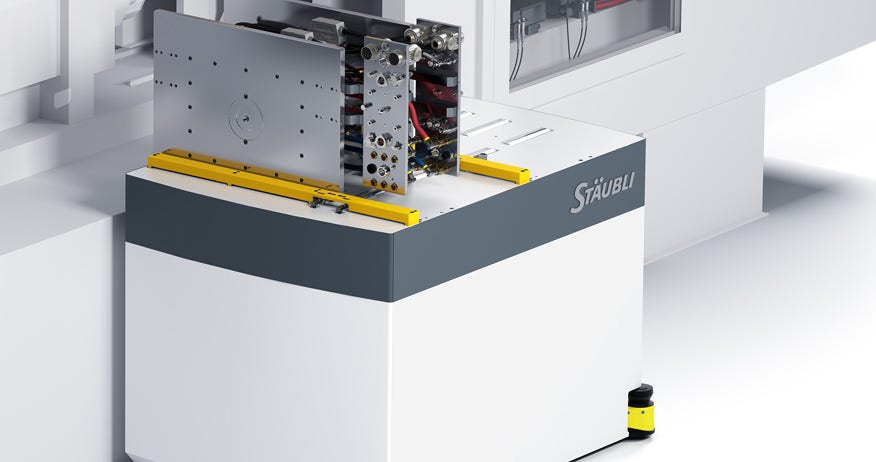

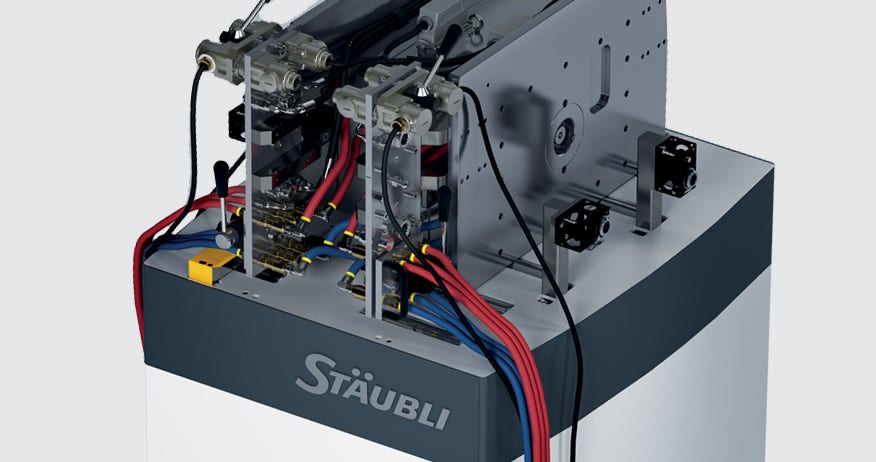

Connection of energy circuits

Quick couplings and centralized connections for the thermal management of molds, hydraulic applications and electric circuits.

Mold clamping

Mechanical, hydraulic or magnetic: three available Staubli clamping technologies that guarantee you the appropriate solution.

Mold preheating

Preheating stations enable the next mold to reach operational temperature while the current mold is still in use. This reduces downtime between mold changes to a minimum.